Aluminum alloy oxidation liquid recovery and cooling equipment crystal elimination system and process

A technology of cooling equipment and cleaning system, applied in the field of aluminum product processing, can solve problems such as waste of tap water, and achieve the effects of reducing labor intensity, eliminating the risk of high-level operations, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

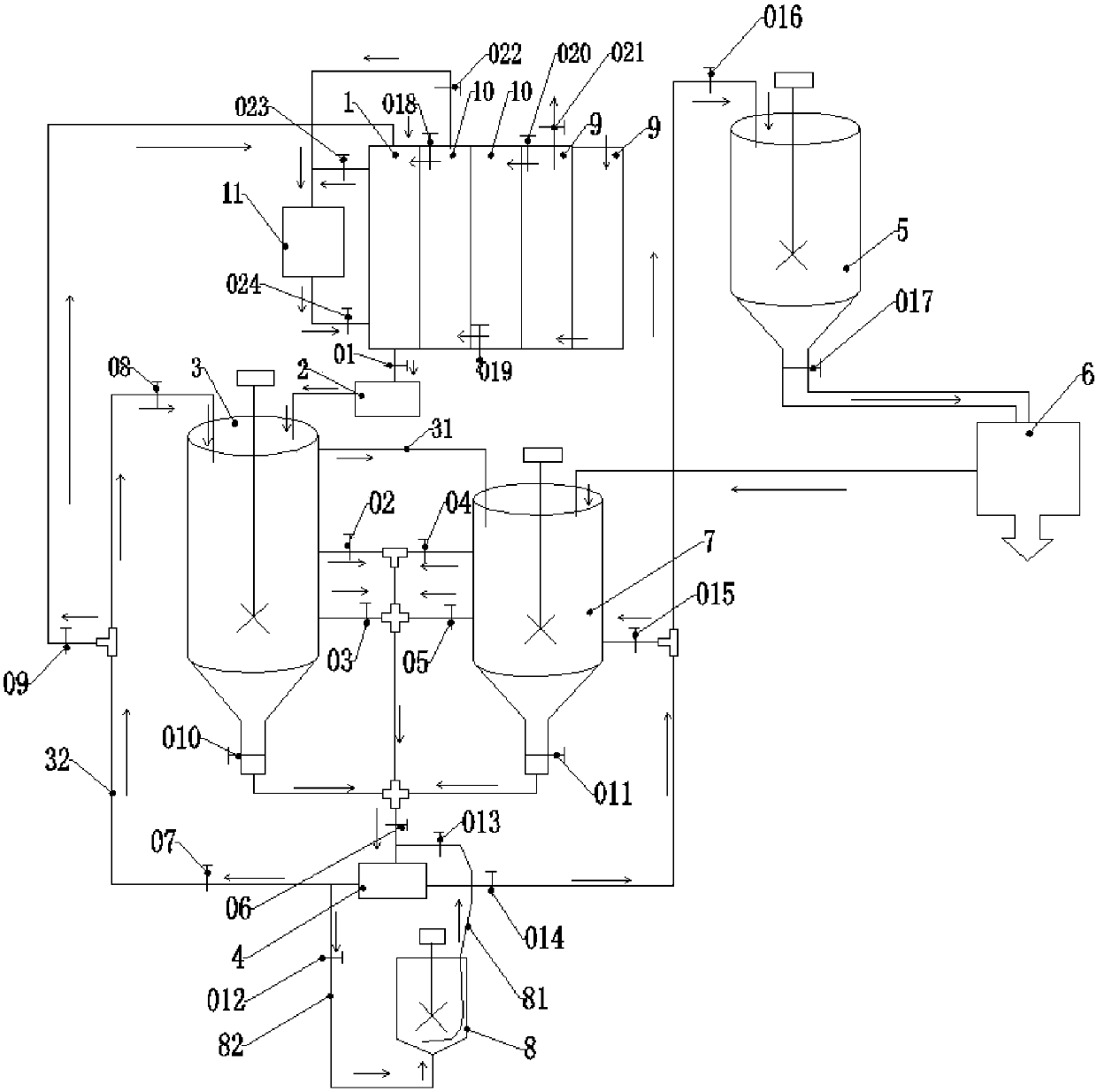

[0068] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0069] 1. Theoretical basis for the recovery of aluminum ions and sulfuric acid in the anodizing solution

[0070] When the aluminum alloy is oxidized, according to formula (3), part of the oxide film is dissolved, and about 4Kg / T (400m2) of aluminum is dissolved into the sulfuric acid oxidation solution. Ammonium sulfate is added to this oxidizing solution, and the following reaction takes place:

[0071] Al 2 (SO 4 ) 3 +(NH 4 ) 2 SO 4 +12H 2 O=2NH 4 Al(SO 4 ) 2 12H 2 O↓ (5)

[0072] Under the conditions of 160-200g / L sulfuric acid, containing aluminum and ammonium ions, ammonium aluminum sulfate NH 4 Al(SO 4 ) 2 12H 2 O crystallizes out, and the amount of residual aluminum ions is related to the crystallization temperature and time.

[0073] 2. Quantitative analysis of experimental results

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com