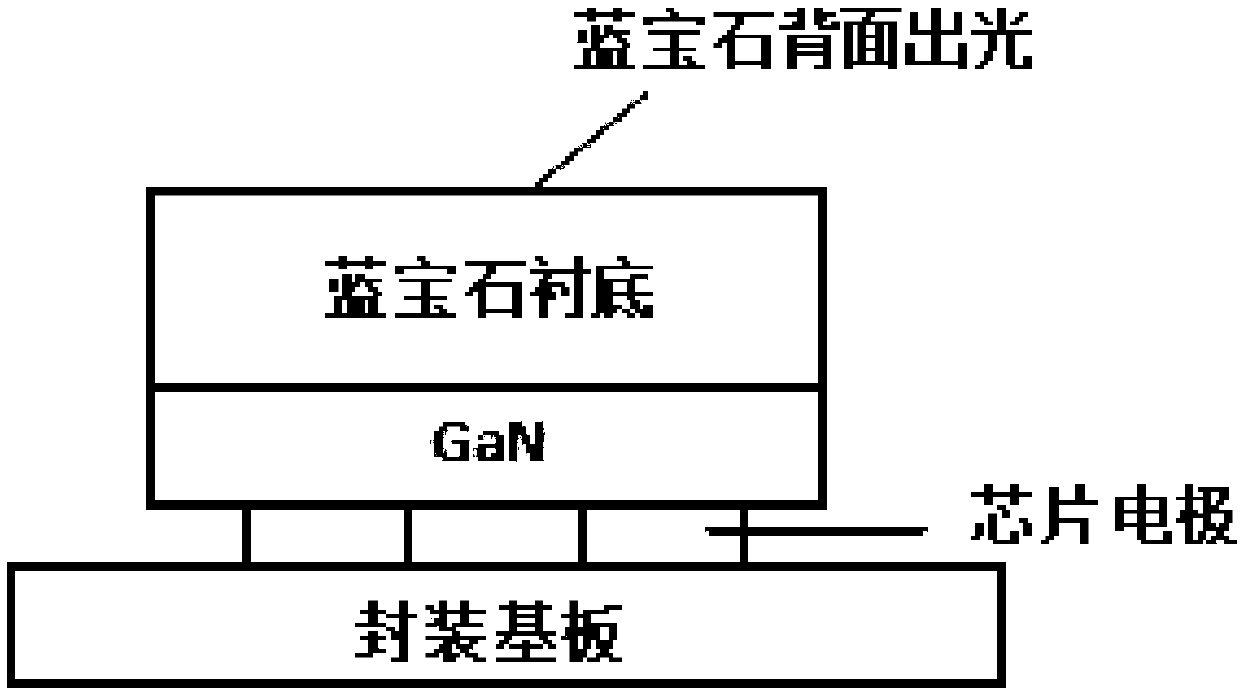

Fabrication method for patterning sapphire light giving-out surface of LED flip chip

A technology of flip chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as difficult application of nanoimprinting technology, sapphire fragmentation, etc., and achieve improved light extraction efficiency, easy operation, and tolerance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

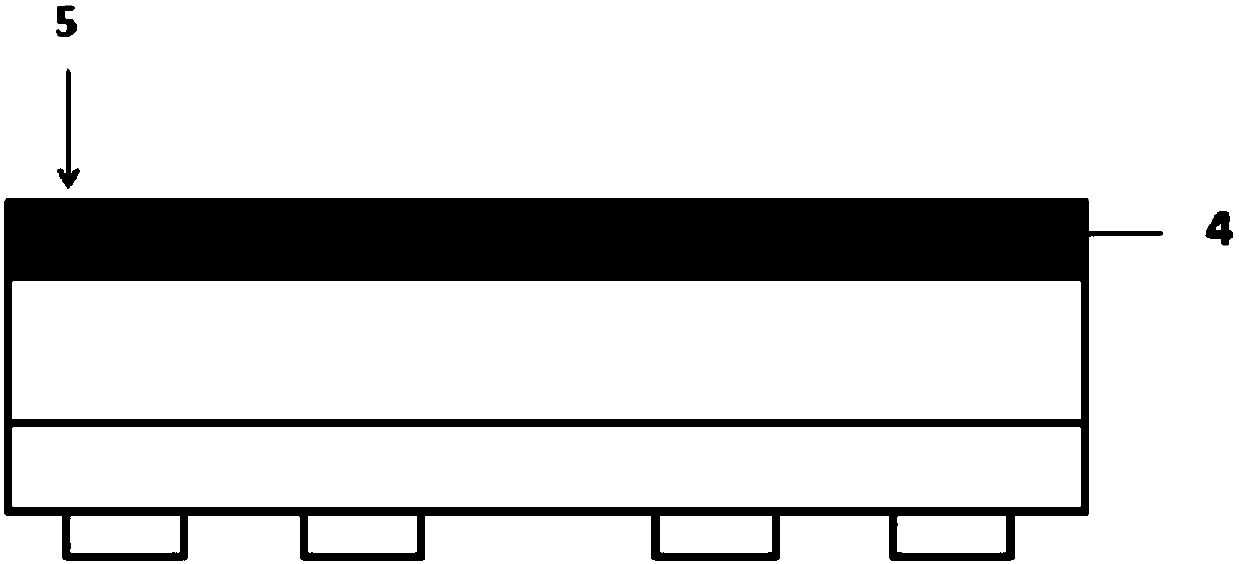

[0027] For the patterning of the sapphire light-emitting surface of LED flip chips, after research, laser direct writing is another feasible lithography method. Its working principle is to control the high-precision laser beam scanning by computer, and directly expose and write Arbitrary graphics designed, so that the design graphics can be directly transferred to the substrate. Laser direct writing lithography, no mask plate required, high graphics resolution, fast lithography writing efficiency, high repeat alignment accuracy, adaptive to changes in the environment and substrate thickness, and easy to operate.

[0028] The specific steps of this process method are as follows:

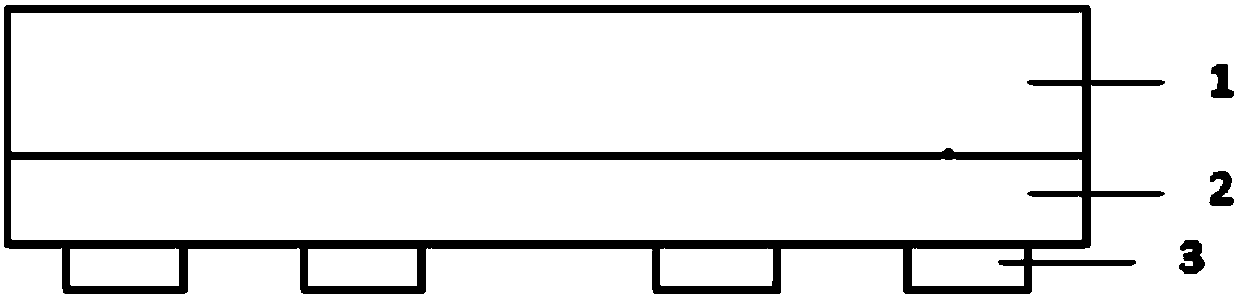

[0029] Step S1, such as figure 2 As shown, the LED chip front-end process is completed by the normal flip-chip process until the sapphire substrate thinning and polishing process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com