A kind of negative pole piece of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative pole pieces, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of heavy electrode materials and achieve the effects of small thickness, effective lithium ion exchange, and large number of thin-layer structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 10g of carboxymethylcellulose aqueous solution with a concentration of 1%, 0.1g of conductive carbon and 0.3g of graphite, and place them in a ball mill for ball milling for 15min. Pour the ground slurry into 10 weighing bottles respectively, and freeze into ice cubes at low temperature. Under the low pressure of 5 Pa, the moisture in the ice cubes is evaporated. The obtained spongy cylinder can be used as a pole piece.

[0018] The lithium sheet is used as the counter electrode and the prepared pole piece is packaged in a 2032 battery case, and the cycle performance test is carried out at a current density of 50mA / g in the battery test system. The test results show that the specific capacity of the pole piece is 300mAh / g , but a 0.5g pole piece can store 150mAh of electricity. And charge and discharge 500 times, the capacity remains unchanged.

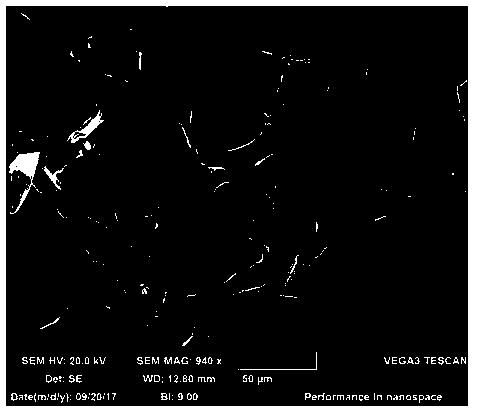

[0019] figure 1 For the thin layer structure when no conductive carbon and active material are added in this embodim...

Embodiment 2

[0022] Take 15g of 2% sodium alginate aqueous solution, 0.3g of conductive carbon and 0.4g of silicon powder, and put them in a ball mill for 15min. Pour the ground slurry into 10 weighing bottles respectively, and freeze into ice cubes at low temperature. Under the low pressure of 5 Pa, the moisture in the ice cubes is evaporated. The obtained spongy cylinder can be used as a pole piece.

[0023] The lithium sheet is used as the counter electrode and the prepared pole piece is packaged in a 2032 type battery case, and the cycle performance test is carried out at a current density of 50mA / g in the battery test system. The test results show that the specific capacity of the pole piece is 1200mAh / g , and the specific capacity remains above 800 mAh / g after 100 charge-discharge cycles.

Embodiment 3

[0025] Take 20g of carboxysodium alginate aqueous solution with a concentration of 0.5%, 0.1g of conductive carbon and 0.3g of graphite, and put them in a ball mill for 15min. Pour the ground slurry into 10 weighing bottles respectively, and freeze into ice cubes at low temperature. Under the low pressure of 5 Pa, the moisture in the ice cubes is evaporated. The obtained spongy cylinder can be used as a pole piece.

[0026] The lithium sheet is used as the counter electrode and the prepared pole piece is packaged in a 2032 battery case, and the cycle performance test is carried out at a current density of 50mA / g in the battery test system. The test results show that the specific capacity of the pole piece is 300mAh / g , but a 0.5g pole piece can store 150mAh of electricity. And charge and discharge 500 times, the capacity remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com