Compound binder of silicon-based negative electrode for lithium ion batteries and preparation method thereof

A lithium-ion battery, silicon-based negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of inconspicuous conductive structure effect, inability to meet silicon-based negative electrodes, etc., to avoid binder structure breakage, suitable for The effect of mass production, maintaining electrical connectivity and mechanical integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

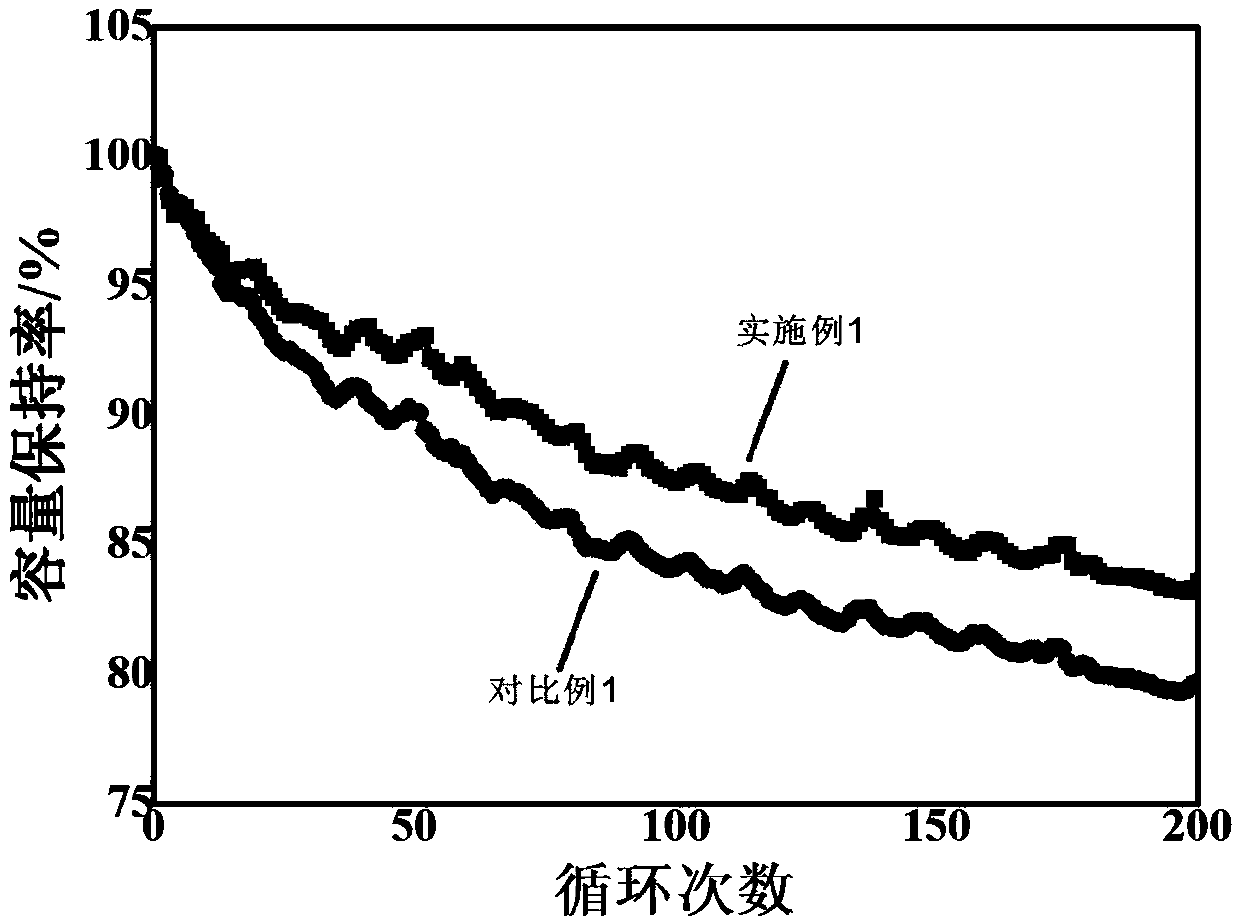

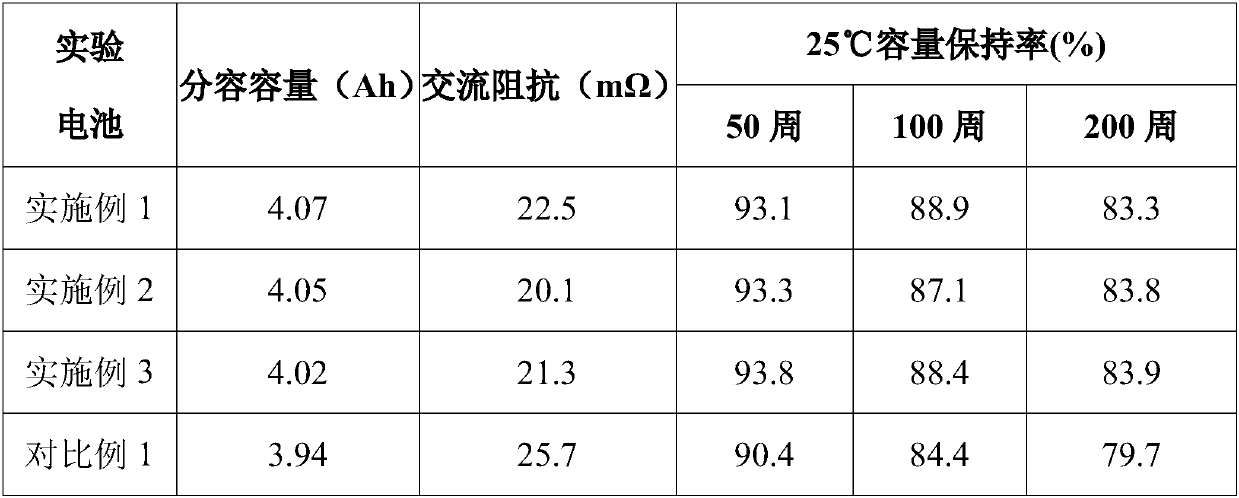

Embodiment 1

[0020] A composite binder for a silicon-based negative electrode of a lithium-ion battery, the raw materials of which include: polyamide-imide and polyaniline, wherein the weight ratio of polyamide-imide and polyaniline is 4:1.

[0021] The preparation method of the composite binder for the silicon-based negative electrode of the lithium-ion battery comprises the following steps: stirring the polyimide copolymer, the conductive polymer, and N-methylpyrrolidone at room temperature for 5 hours, and then heating up to 60° C. Medium-baking for 5 hours to remove N-methylpyrrolidone, then high-speed ball milling for 3 hours, heating up to 60° C., and drying in an oven for 5 hours to obtain a composite binder for silicon-based negative electrodes of lithium-ion batteries.

Embodiment 2

[0023] A composite binder for a silicon-based negative electrode of a lithium ion battery, the raw materials of which include polyimide and polypyrrole, wherein the weight ratio of polyimide and polypyrrole is 10:1.

[0024] The preparation method of the composite binder of the silicon-based negative electrode of the lithium-ion battery comprises the following steps: stirring the polyimide copolymer, the conductive polymer, and N-methylpyrrolidone at room temperature for 10 hours, and then raising the temperature to 80° C. Medium-baked for 10 hours to remove N-methylpyrrolidone, then high-speed ball milled for 5 hours, heated to 80° C., and baked in an oven for 5 hours to obtain a composite binder for silicon-based negative electrodes of lithium-ion batteries.

Embodiment 3

[0026] A composite binder for silicon-based negative electrodes of lithium-ion batteries, the raw materials of which include: polyetherimide and polyethylenedioxythiophene, wherein the weight ratio of polyetherimide and polyethylenedioxythiophene is 6 :1.

[0027] The preparation method of the composite binder of the silicon-based negative electrode of the lithium-ion battery comprises the following steps: stirring the polyimide copolymer, the conductive polymer, and N-methylpyrrolidone at room temperature for 8 hours, and then raising the temperature to 70° C. Medium-baked for 8 hours to remove N-methylpyrrolidone, then high-speed ball milled for 4 hours, heated to 70°C, and baked in an oven for 8 hours to obtain a composite binder for silicon-based negative electrodes of lithium-ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com