3D printed fang implant with multisection structure

A 3D printing and implant technology, which is applied in the fields of implantology, dentistry, and dental prosthetics, etc., can solve problems such as poor mechanical compatibility, implantation success rate, long-term life expectancy, high manufacturing cost, etc., and achieve improved stability , Improve the cutting performance and bone grip performance, and increase the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

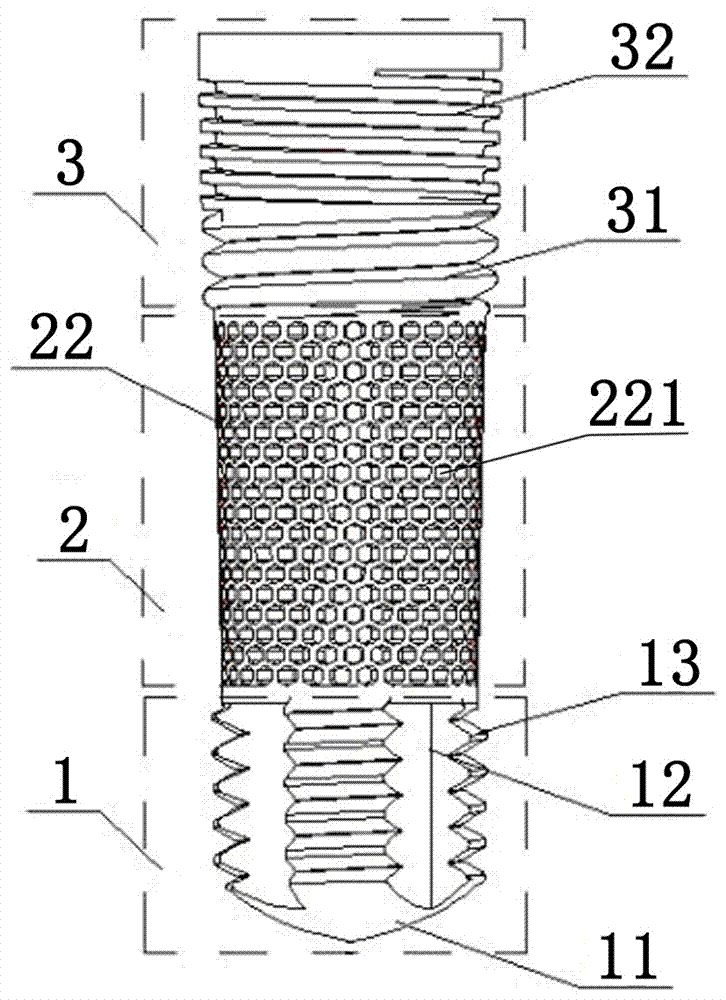

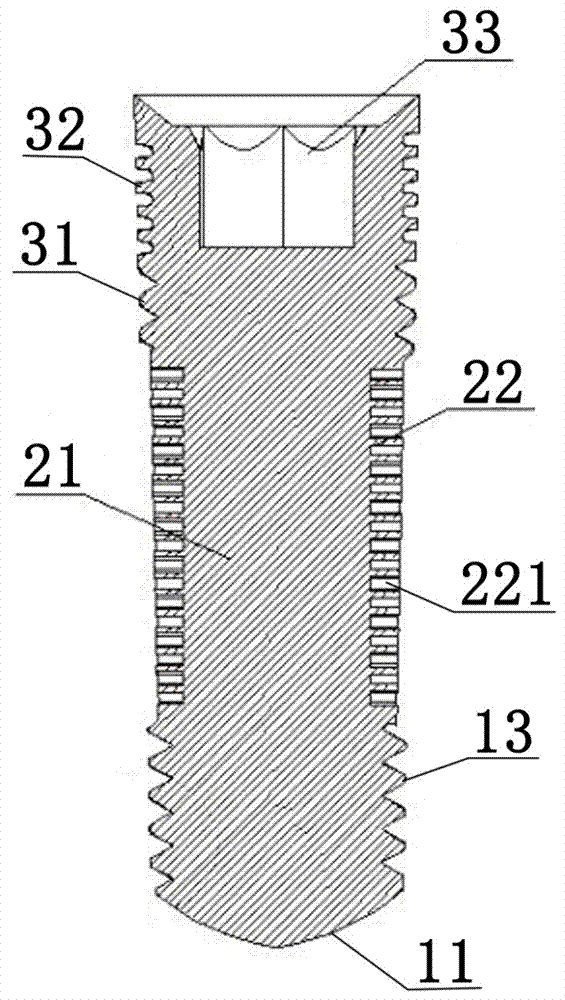

[0020] like Figure 1-Figure 2 As shown, the 3D printed root implant with multi-segment structure of the present invention is formed by one-time printing by 3D laser melting (SLM), so no processing or cutting is required. Furthermore, the root implant comprises a lower threaded section 1 , an intermediate body section 2 and an upper threaded section 3 .

[0021] Wherein, the intermediate section 2 is a connecting area between the upper threaded section 3 and the lower threaded section 1 with a stable hollow shell-like structure, which is the core part of the present invention. It includes a solid cylinder 21 and a honeycomb shell structure 22 wrapped on the outer surface of the solid cylinder 21, and the densely distributed holes 221 on the honeycomb shell structure 22 are regular polygonal holes or circular holes. When the hole 221 is a regular polygonal hole, a circular arc transition is required at the sharp corner to reduce stress concentration. Also, the regular polygon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com