Lifetime prolonging method for crankshaft bending upsetting forming die

A technology for forming molds and bending, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. It can solve the problem of poor stress conditions of thin-walled structures, affecting product production progress, and poor mold working conditions. and other problems, to achieve the effect of improving the working conditions of continuous high temperature and high load, outstanding flexibility, and improved impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

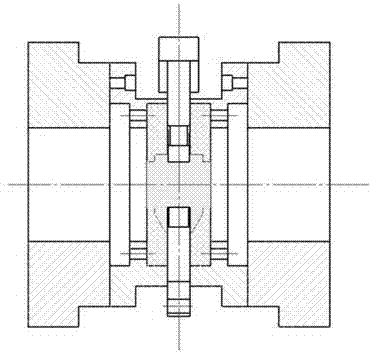

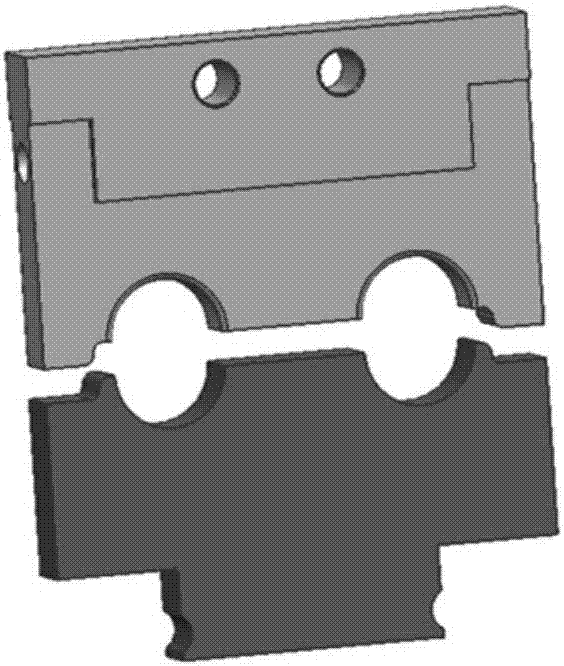

[0040] A method for extending the life of an RSV92-C crankshaft bending upsetting forming die, comprising the following steps:

[0041] 1. Forge the H13 steel ingot with a forging ratio of 3.7 to the approximate size of the mold core of φ500mm×130mm;

[0042] 2. Anneal the core forging blank at a temperature of 1050°C±20°C;

[0043] 3. Reserve 2mm for the annealed mold core forging blank according to the cavity size to the mold core size;

[0044] 4. The rough-processed mold core shall be processed according to the "double cycle quenching + tempering (1160℃±20℃×1h quenching + 600℃×2h tempering) + (1040℃±20℃×1h quenching + 600℃×2h quenching) Fire)" process for quenching and tempering;

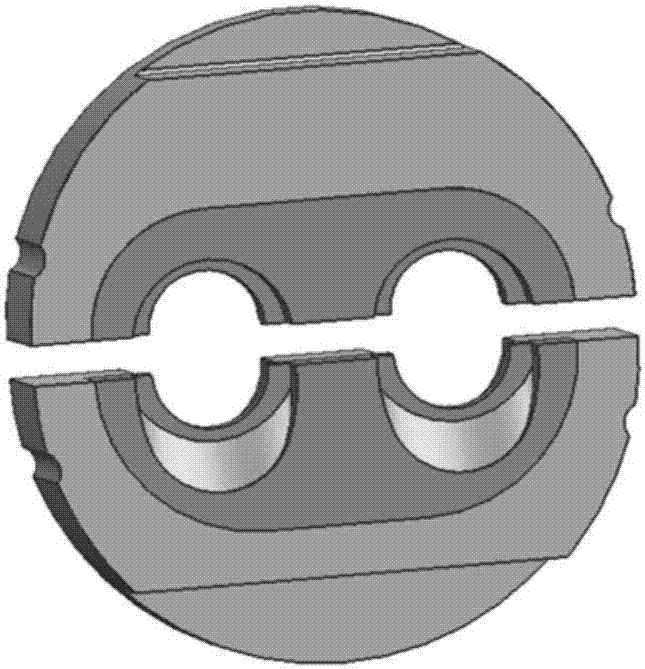

[0045] 5. The quenched and tempered mold core is finished according to the size of the cavity, and the two cavities have the same size and are symmetrically distributed along the center;

[0046] 6. Double surface strengthening treatment is carried out on the finished mold by surface nitridin...

Embodiment 2

[0053] A method for extending the life of a JDB26-C crankshaft bending upsetting forming die, comprising the following steps:

[0054] 1. Forge the H13 steel ingot with a forging ratio of 3.6 to the approximate size of the mold core of φ500mm×150mm;

[0055] 2. Anneal the core forging blank at a temperature of 1050°C±20°C;

[0056] 3. Reserve 2mm for the annealed mold core forging blank according to the cavity size to the mold core size;

[0057] 4. The rough-processed mold core shall be processed according to the "double cycle quenching + tempering (1160℃±20℃×1h quenching + 600℃×2h tempering) + (1040℃±20℃×1h quenching + 600℃×2h quenching) Fire)" process for quenching and tempering;

[0058]5. The quenched and tempered mold core is finished according to the size of the cavity, and the two cavities have the same size and are symmetrically distributed along the center;

[0059] 6. Double surface strengthening treatment is carried out on the finished mold by surface nitriding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com