Durable antibacterial water-based acrylic resin and preparation method thereof

A water-based acrylic acid and acrylic acid technology, which is applied in the preparation of carboxylic acid halide, the preparation of imino compounds, antifouling/underwater coatings, etc., can solve the problems of poor durability of antibacterial effect, easy degradation, and easy elution, and achieves applicability Wide, good adhesion, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

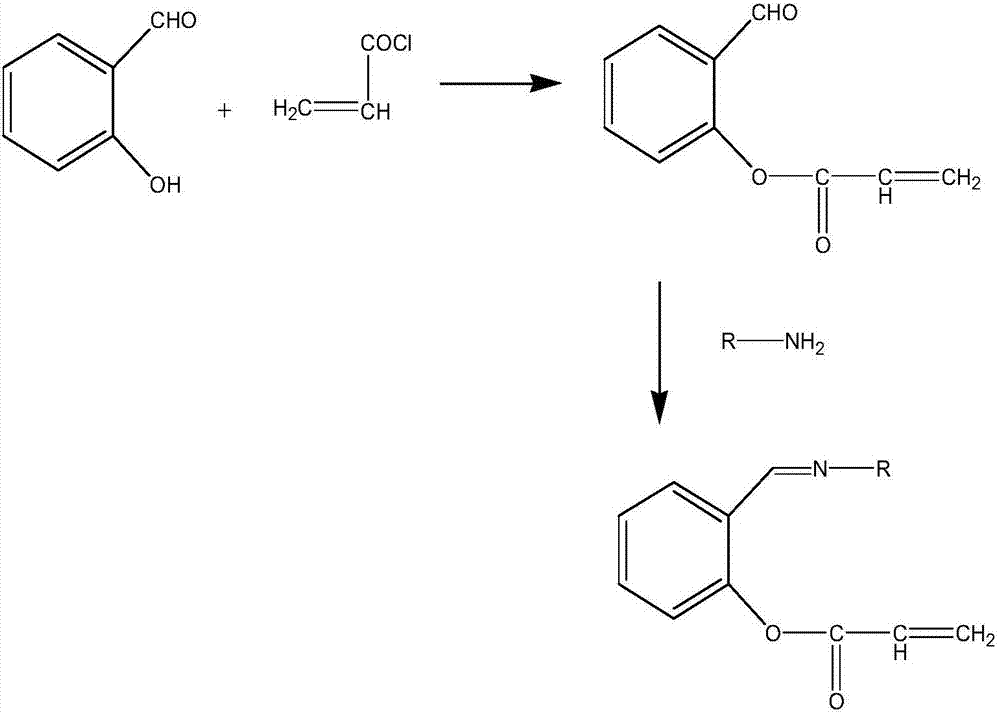

[0032] A kind of Schiff base acrylic acid monomer A, prepared by the following steps:

[0033] a) Weigh 18.0 parts of salicylaldehyde and 10.2 parts of potassium carbonate in the reaction kettle in sequence, add 5.0 parts of N,N-dimethylformamide, stir to dissolve evenly, raise the temperature to 80°C for 1 hour, and then add 13.3 parts of acryloyl chloride part and 0.06 part of potassium iodide, keep reflux reaction for 12h, then cool, wash with water until neutral, dry, and recrystallize to obtain the reactant intermediate I;

[0034] b) In a reaction kettle equipped with a thermometer, agitator, and condenser, add reactant intermediate I and 10.0 parts of ethanol, heat up to 80°C and stir to dissolve evenly; in addition, weigh 27.3 parts of dodecylamine and 15.44 parts of ethanol to dissolve After uniformity, add dropwise to the reaction kettle at a uniform speed. After the dropwise addition, add 0.7 parts of glacial acetic acid, keep the reflux reaction for 4-5 hours, cool...

Embodiment 2

[0036] A kind of Schiff base acrylic acid monomer B, prepared by the following steps:

[0037] a) Weigh 20.0 parts of salicylaldehyde and 11.4 parts of potassium carbonate in the reaction kettle in sequence, add 6.0 parts of N,N-dimethylformamide, stir to dissolve evenly, raise the temperature to 80°C for 1 hour, and then add 14.8 parts of acryloyl chloride part and 0.05 part of potassium iodide, keep reflux reaction for 12h, then cool, wash with water until neutral, dry, and recrystallize to obtain the reactant intermediate I;

[0038] b) In a reaction kettle equipped with a thermometer, agitator, and condenser, add the reactant intermediate I and 20.0 parts of ethanol, heat up to 80°C and stir to dissolve evenly; in addition, weigh 15.2 parts of aniline and 11.85 parts of ethanol to dissolve evenly , dropwise into the reaction kettle at a uniform speed, after the dropwise addition, add 0.7 parts of glacial acetic acid, keep the reflux reaction for 4 to 5 hours, cool to room ...

Embodiment 3

[0040] A kind of Schiff base acrylic acid monomer C, prepared by the following steps:

[0041]a) Weigh 25.0 parts of salicylaldehyde and 14.2 parts of potassium carbonate in the reaction kettle in sequence, add 8.0 parts of N,N-dimethylformamide, stir to dissolve evenly, raise the temperature to 80°C for 1 hour, and then add 18.5 parts of acryloyl chloride part and 0.06 part of potassium iodide, keep reflux reaction for 12h, then cool, wash with water until neutral, dry, and recrystallize to obtain the reactant intermediate I;

[0042] b) In a reaction kettle equipped with a thermometer, a stirrer, and a condenser, add the reactant intermediate I and 10.0 parts of ethanol, heat up to 80°C and stir to dissolve evenly; in addition, weigh 15.4 parts of isopropanolamine and 7.94 parts of ethanol After the solution is evenly dissolved, add it dropwise into the reaction kettle at a uniform speed. After the dropwise addition, add 0.9 parts of glacial acetic acid and keep it under ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com