Acid-base reversible crosslinking organic silicon resin and preparation method thereof

A technology for cross-linking organosilicon and organosilicon, which is applied in the field of acid-base reversible cross-linking organosilicon resin and its preparation, can solve the problem that organosilicon resin is not recycled, and achieves the effect of excellent processing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

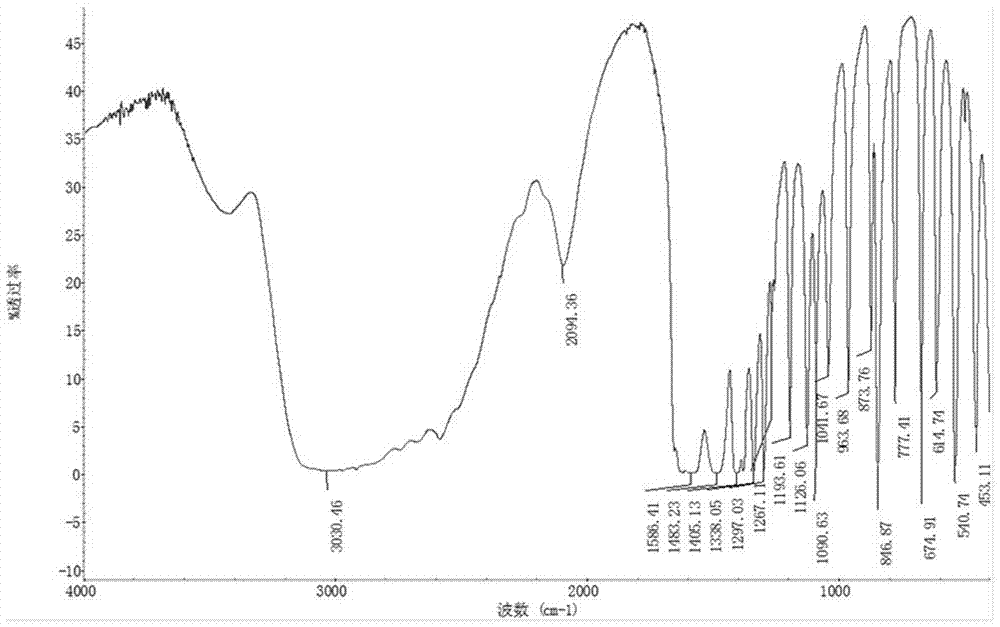

Image

Examples

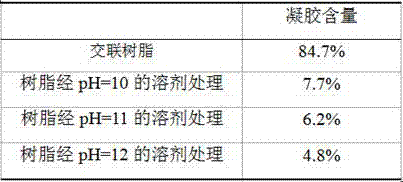

Embodiment 1

[0019] Epoxy-terminated silicone oil and L-cystine were dissolved in γ-(2,3-glycidyloxy)propyltrimethoxysilane at a mass ratio of 100:5, and 5wt‰ of sodium ethylate was added as a catalyst at room temperature. After 1 hour of ring-opening reaction, an acid-base reversible cross-linking silicone resin is obtained. The acid-base reversible cross-linking silicone resin device or film is formed at 75°C, and can be formed through additive manufacturing technology, molding and other processing techniques.

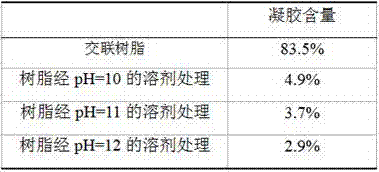

Embodiment 2

[0021] Dissolve vinyl-terminated silicone oil and diallyl disulfide in γ-methacryloxypropyltrimethoxysilane at a mass ratio of 100:3, add 10wt‰ of dibenzoyl peroxide as catalyst, 80°C The free radical reaction was carried out for 2 hours to obtain an acid-base reversible cross-linking silicone resin. The acid-base reversible cross-linking silicone resin device or film is formed at 80°C, and can be formed through additive manufacturing technology, molding and other processing techniques.

Embodiment 3

[0023] Amino-terminated silicone oil and L-homocystine were dissolved in the medium at a mass ratio of 100:6, 10wt‰ of sodium bromide was added as a catalyst, and the reaction was carried out at 70°C for 2.5 hours to obtain an acid-base reversible cross-linked silicone resin. The acid-base reversible cross-linking silicone resin device or film is formed at 60°C, and can be formed through additive manufacturing technology, molding and other processing techniques.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com