Preparation method of metal coating on surface of carbon fiber composite material

A composite material and surface metal technology, which is applied to the device, coating, epoxy resin coating and other directions of coating liquid on the surface, can solve the problems of decreasing the strength of carbon fiber composite materials, damaging the surface of the substrate, reducing the bonding strength, etc. The effect of improving bond strength, avoiding thermal damage, and increasing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

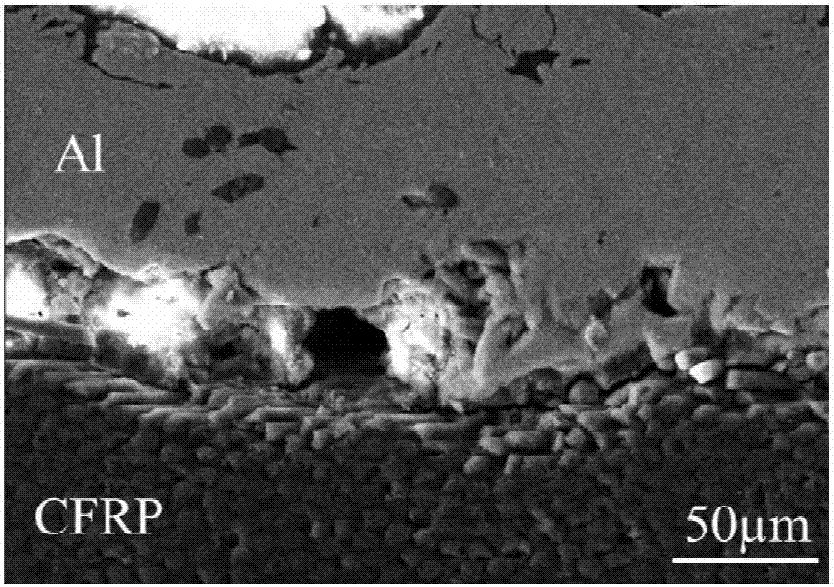

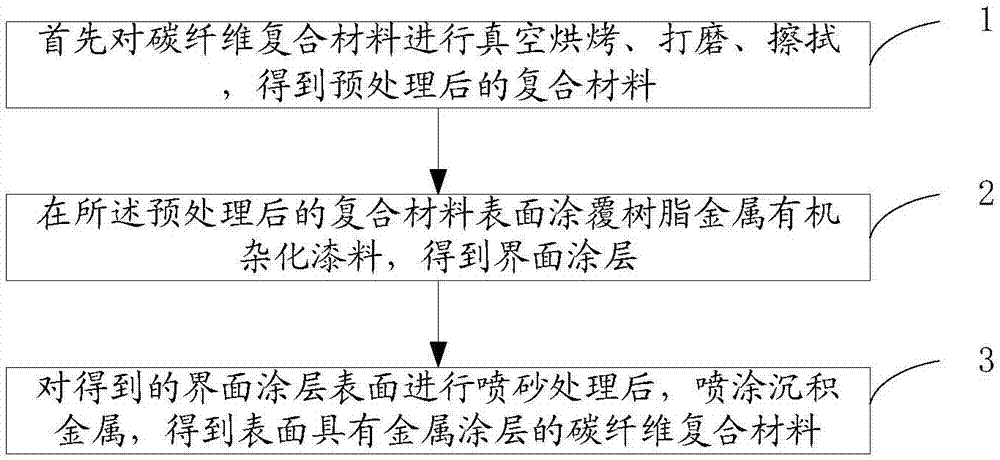

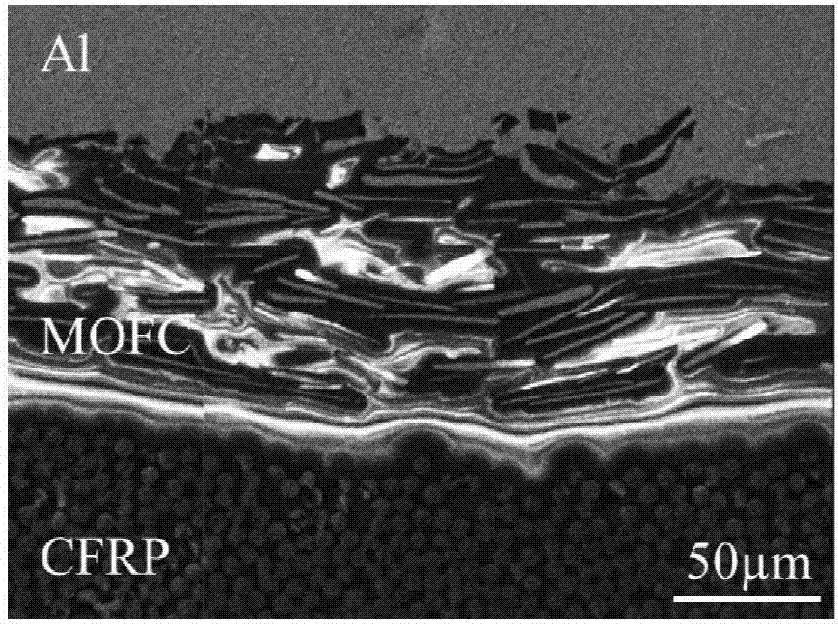

[0033] see figure 2 , the embodiment of the present invention provides a method for preparing a metal coating on the surface of a carbon fiber composite material, comprising the following steps:

[0034] Step 1. First, vacuum bake, polish and wipe the carbon fiber composite material to obtain the pretreated composite material;

[0035] Specifically, the carbon fiber composite material may be carbon fiber / epoxy 648 resin-based composite material, carbon fiber / cyanate resin-based composite material, carbon fiber / phenolic resin-based composite material, etc., which are not limited in the present invention;

[0036] Step 2, coating resin-metal-organic hybrid paint on the surface of the pretreated composite material to obtain an interface coating;

[0037] Specifically, the resin metal-organic hybrid paint is a paint obtained by organic hybridization of resin and metal; the resin can be epoxy resin, phenolic resin, polyester resin, etc., preferably the matrix resin of carbon fibe...

Embodiment 1

[0054] This embodiment provides a carbon fiber composite material with a metal coating, and its preparation method includes:

[0055] Step 1. Put the carbon fiber / epoxy 648 resin-based composite material into a vacuum oven for pretreatment, with a heating temperature of 100°C and a heating time of 12 hours.

[0056] Step 2. Polish the surface of the carbon fiber composite material pretreated in step 1 to a matte state with 600# sandpaper, and then gently wipe the surface with absolute ethanol for use.

[0057] Step 3. Prepare the aluminum powder-resin metal-organic hybrid paint material. The configuration process is as follows: dissolve 70g of epoxy resin in 70g of butyl acetate, and stir for 1 hour at the stirring speed of 350r / min to obtain component A; Dissolve 30g of aluminum powder in 60g of butyl acetate, and stir for 1 hour at a stirring paddle speed of 350r / min to prepare component B; mix components A and B, and stir for 3 hours at a stirring paddle speed of 350r / min ...

Embodiment 2

[0063] This embodiment provides a carbon fiber composite material with a metal coating, and its preparation method includes:

[0064] Step 1. Put the carbon fiber / cyanate resin-based composite material into a vacuum oven for pretreatment, with a heating temperature of 120°C and a heating time of 10 hours.

[0065] Step 2. Polish the surface of the carbon fiber composite material pretreated in step 1 to a matte state with 400# sandpaper, and then gently wipe the surface with absolute ethanol for use.

[0066] Step 3. Prepare aluminum powder-resin metal hybrid paint. The configuration process is as follows: Dissolve 50g of epoxy resin in 50g of butyl acetate, and stir for 1 hour at a stirring speed of 400r / min to obtain component A; Dissolve 50g of aluminum powder in 60g of butyl acetate, and stir for 1 hour at a stirring paddle speed of 400r / min to prepare component B; mix components A and B at a stirring paddle speed of 400r / min for 3 hours An interface coating paint is prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com