Anti-static peelable protective glue composition and preparation method thereof

An antistatic and composite technology, which is applied in the field of antistatic peelable protective glue composition and its preparation, can solve the problems of static electricity and dust adsorption of electronic circuit boards, and achieve better protection performance, superior film-forming performance, and coating The method is simple and convenient, and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

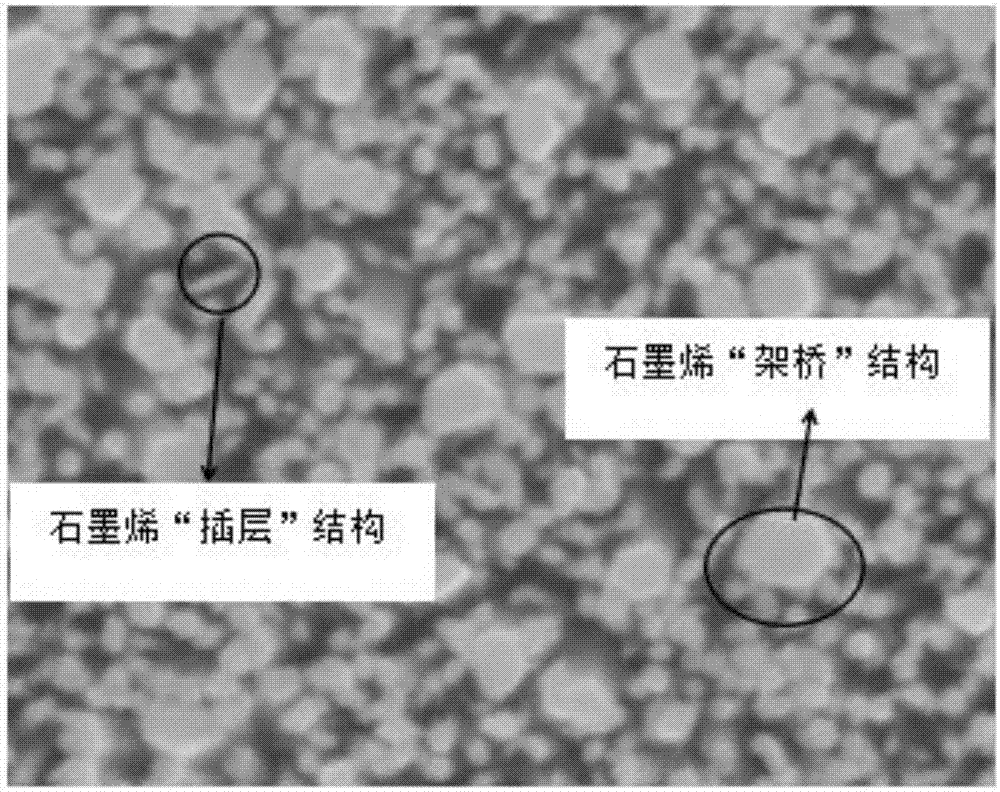

Image

Examples

Embodiment 1

[0038] This embodiment relates to a preparation method of a graphene / ZnO synergistic antistatic peelable protective glue composition, which specifically includes the following steps:

[0039] 1. According to the following ratio of raw materials for batching:

[0040]

[0041] The film-forming resin is composed of chlorinated polyethylene and high-chlorinated polyethylene in a weight ratio of 1:3;

[0042] 2. Add the solvent into a 20L temperature-controllable reaction kettle, raise the temperature to 65°C, start the agitator to stir at a stirring speed of 100r / min, add the film-forming resin and stir for 0.5h until the film-forming resin is completely dissolved in the solvent, and then After adding thickener, anti-sedimentation agent, coupling agent, leveling agent, defoamer, and stripping agent, adjust the stirring speed to 200r / min, and finally add graphene and ZnO, and discharge after stirring evenly to obtain graphite Oxene / ZnO synergistic antistatic peelable protectiv...

Embodiment 2

[0046] This embodiment relates to a preparation method of a graphene / ZnO synergistic antistatic peelable protective glue composition, which specifically includes the following steps:

[0047] 1. According to the following ratio of raw materials for batching:

[0048]

[0049] The film-forming resin is composed of chlorinated polyethylene and high-chlorinated polyethylene in a weight ratio of 1:4;

[0050] 2. Add the solvent into a 20L temperature-controllable reaction kettle, raise the temperature to 65°C, start the agitator to stir at a stirring speed of 100r / min, add the film-forming resin and stir for 0.5h until the film-forming resin is completely dissolved in the solvent, and then After adding thickener, anti-sedimentation agent, coupling agent, leveling agent, defoamer, and stripping agent, adjust the stirring speed to 200r / min, and finally add graphene and ZnO, and discharge after stirring evenly to obtain graphite Oxene / ZnO synergistic antistatic peelable protectiv...

Embodiment 3

[0053] This embodiment relates to a preparation method of a graphene / ZnO synergistic antistatic peelable protective glue composition, which specifically includes the following steps:

[0054]1. According to the following ratio of raw materials for batching:

[0055]

[0056]

[0057] The film-forming resin is composed of chlorinated polyethylene and high-chlorinated polyethylene in a weight ratio of 1:5.

[0058] 2. Add the solvent into a 20L temperature-controllable reaction kettle, raise the temperature to 65°C, start the agitator to stir at a stirring speed of 100r / min, add the film-forming resin and stir for 0.5h until the film-forming resin is completely dissolved in the solvent, and then After adding thickener, anti-sedimentation agent, coupling agent, leveling agent, defoamer, and stripping agent, adjust the stirring speed to 200r / min, and finally add graphene and ZnO, and discharge after stirring evenly to obtain graphite Oxene / ZnO synergistic antistatic peelabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com