Production method of magnesium alloy etching plate by using protective film instead of back anticorrosion paint

A production method and technology of magnesium alloys, which are applied in the direction of temperature recording method, metal processing equipment, grinding machines, etc., can solve the problems of time-consuming and laborious, physical health injury of operators, environmental pollution, etc., so as to reduce environmental pollution, shorten production time, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

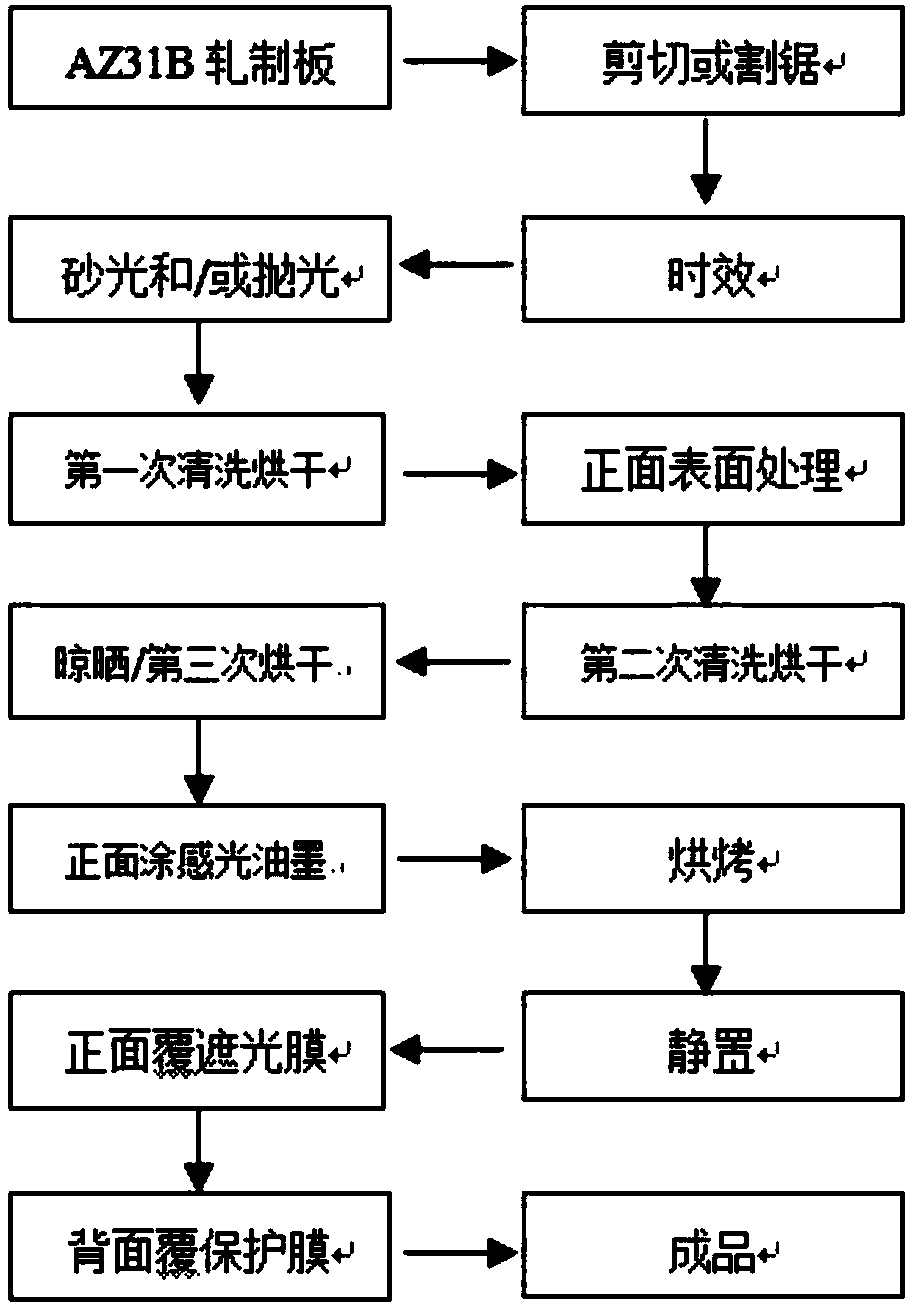

[0034] 1000mm×500mm×7.0mm pre-coated magnesium alloy etching plate production process, such as figure 1 Shown:

[0035]Qualified 7.3-7.5mm thick AZ31B magnesium alloy rolling strip (mass percentage content of manganese is less than 0.25%, calcium content is 0.002%, grain size≤10μm) is cut to a width of 500mm and The length is 1000mm, and the tolerance of length and width is ±3mm. Then stack them together and put them into a box-type aging furnace, apply a uniform force, heat the aging furnace to 280°C, store for 4 hours, and then cool with the furnace.

[0036] After aging, the magnesium alloy plate is sanded with an 80-mesh sander until the thickness is between 7.10 and 7.15 mm, and then sanded with a 240-mesh and 600-mesh sander until the thickness is between 7.01 and 7.07 mm. The plate after sanding is directly sent to the washing and drying machine for washing and drying, and the drying temperature is set at 150°C; this process must ensure that the surface roughness of t...

Embodiment 2

[0042] 1000mm×500mm×7.0mm pre-coated magnesium alloy etching plate production process:

[0043] Qualified 7.3-7.5mm thick AZ31B magnesium alloy rolling strip (mass percentage content of manganese is less than 0.25%, calcium content is 0.004%, grain size≤10μm) is cut to a width of 500mm and The length is 1000mm, and the tolerance of length and width is ±3mm. Then stack them together and put them into a box-type aging furnace, apply a uniform force, heat the aging furnace to 250°C, store for 6 hours, and then cool with the furnace.

[0044] After aging, the magnesium alloy plate is sanded with an 80-mesh sander until the thickness is between 7.10 and 7.15 mm, and then sanded with a 240-mesh and 600-mesh sander until the thickness is between 7.01 and 7.07 mm. The plate after sanding is sent directly to the washing and drying machine for washing and drying, and the drying temperature is set at 180°C; in this process, the surface roughness of the front side, that is, the photosens...

Embodiment 3

[0050] 1000mm×500mm×7.0mm pre-coated magnesium alloy etching plate production process:

[0051] Qualified 7.3-7.5mm thick AZ31B magnesium alloy rolling strip (the mass percent content of manganese is less than 0.25%, the mass percent content of calcium is 0.06%, grain size≤10μm) is cut to a width of 500mm and The length is 1000mm, and the tolerance of length and width is ±3mm. Then stack them together and put them into a box-type aging furnace, apply a uniform force, heat the aging furnace to 320 ° C, store for 1 hour, and then cool with the furnace.

[0052] After aging, the magnesium alloy plate is sanded with an 80-mesh sander until the thickness is between 7.10 and 7.15 mm, and then sanded with a 240-mesh and 600-mesh sander until the thickness is between 7.01 and 7.07 mm. The plate after sanding is sent directly to the washing and drying machine for washing and drying, and the drying temperature is set at 180°C; in this process, the surface roughness of the front side, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com