Paraffin-hydrophobic polysilsesquioxane aerogel composite sized phase-change material and preparation method thereof

A technology of polysilsesquioxane and shape-setting phase-change materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, and can solve the problems of large volume changes of polymer carriers, low load capacity of phase-change materials, low temperature resistance and Inflammable and other problems, achieve low cost, simple preparation process, and improve heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

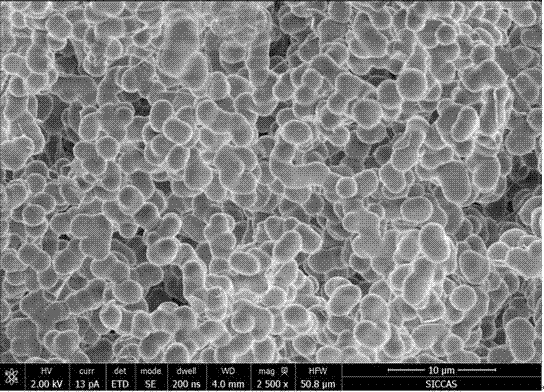

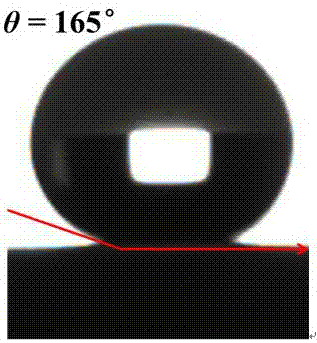

[0036] Hydrophobic polysilsesquioxane airgel is prepared by mixing and stirring alkyl group-containing trialkoxysilane with distilled water to obtain a transparent solution, wherein the content of alkyl group-containing trialkoxysilane is 16wt %, and then add concentrated ammonia water to adjust the pH value of the solution to 11.5 to make the solution gel to obtain a gel; soak the gel in distilled water and age it at 70°C for 20 h, and then dry the aged gel naturally under normal pressure Or heating and drying to prepare bulky hydrophobic polysilsesquioxane airgel. The prepared hydrophobic polysilsesquioxane airgel has a contact angle of 175° and a density of 0.07 g cm -3 , the porosity is 96%, and the pore size distribution is 200~1200 nm.

[0037] Heat the paraffin to melt to a temperature of 100°C.

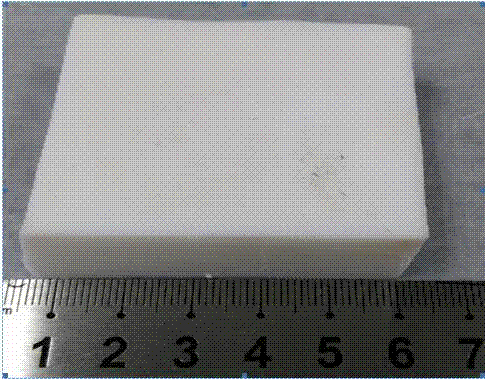

[0038] The hydrophobic polysilsesquioxane airgel is immersed in the molten paraffin liquid to fill the pores of the airgel with paraffin, and the paraffin / hydrophobic polysi...

Embodiment 2

[0040] Hydrophobic polysilsesquioxane airgel is prepared by mixing and stirring alkyl group-containing trialkoxysilane with distilled water to obtain a transparent solution, wherein the content of alkyl group-containing trialkoxysilane is 20wt %, then add concentrated ammonia water to adjust the pH value of the solution to 11.0 to gel the solution to obtain a gel; soak the gel in distilled water and age it at 60°C for 16 h, and then dry the aged gel naturally under normal pressure Or heating and drying to prepare bulky hydrophobic polysilsesquioxane airgel. The prepared hydrophobic polysilsesquioxane airgel has a contact angle of 165° and a density of 0.12 g cm -3 , the porosity is 92.9%, and the pore size distribution is 120~1000 nm.

[0041] Heat the paraffin to melt to a temperature of 120°C.

[0042]The hydrophobic polysilsesquioxane airgel is immersed in the molten paraffin liquid to fill the pores of the airgel with paraffin, and the paraffin / hydrophobic polysilsesquio...

Embodiment 3

[0044] Hydrophobic polysilsesquioxane airgel is prepared by mixing and stirring alkyl group-containing trialkoxysilane with distilled water to obtain a transparent solution, wherein the content of alkyl group-containing trialkoxysilane is 24wt %, and then add concentrated ammonia water to adjust the pH value of the solution to 10 to make the solution gel to obtain a gel; soak the gel in distilled water and age it at 50°C for 14 h, and then dry the aged gel naturally under normal pressure Or heating and drying to prepare bulky hydrophobic polysilsesquioxane airgel. The prepared hydrophobic polysilsesquioxane airgel has a contact angle of 154° and a density of 0.18 g cm -3 , the porosity is 89.3%, and the pore size distribution is 60~760 nm.

[0045] The paraffin is heated and melted so that its temperature reaches 160°C.

[0046] The hydrophobic polysilsesquioxane airgel is immersed in the molten paraffin liquid to fill the pores of the airgel with paraffin, and the paraffin / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com