Process and equipment for recycling waste engine oil

A technology of waste oil and reuse, applied in the direction of lubricating compositions, etc., can solve the problems of tower blockage, high viscosity and short operating cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

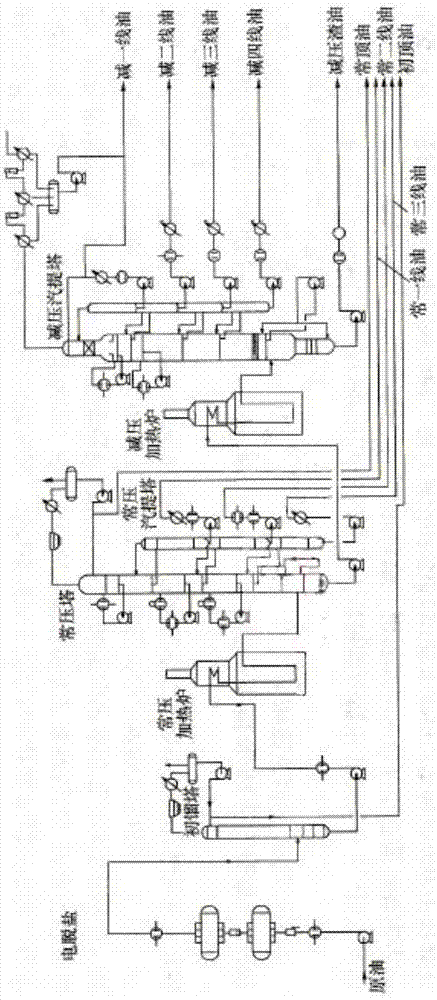

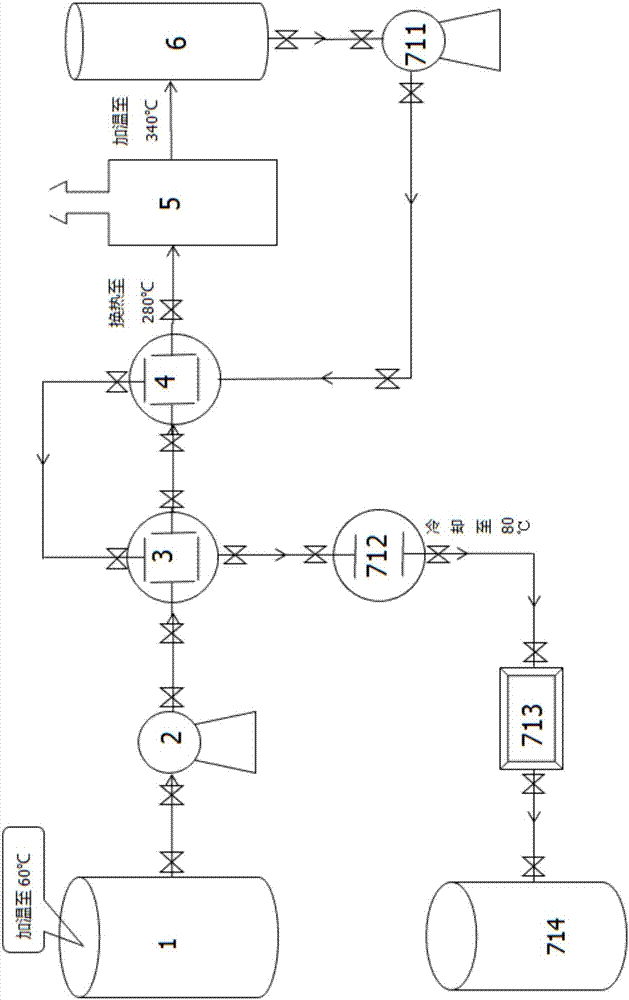

[0037] A process for recovering and reusing waste engine oil, comprising an atmospheric and vacuum distillation process, the atmospheric and vacuum distillation process including electric desalination, initial distillation, atmospheric distillation and vacuum distillation, and also including The pretreatment process, the pretreatment process includes the following steps: as figure 2 As shown, the waste engine oil is heated to 60°C in the storage tank 1, then heated to 280°C by the crude oil pump 2 to the first heat exchanger 3, then to the second heat exchanger 4, and then heated to 280°C by the vertical tubular heating furnace 5. 330-350°C, enter the flash tower 6, the bottom material of the flash tower is sent to the second heat exchanger 4 through the tower bottom pump 711, passes through the first heat exchanger 3, and then is cooled to 70-90°C by the water cooler 712 , filter out impurities through filter 713 to obtain raw material oil.

[0038] Preferably, it is heated...

Embodiment 2

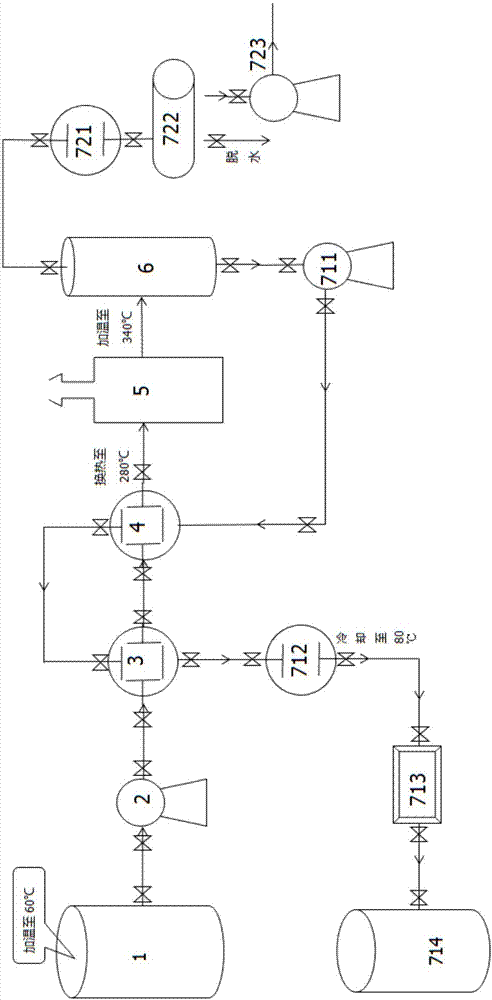

[0043] The difference from Example 1 is that, as image 3 As shown, it also includes that the overhead material of the flash tower passes through the third heat exchanger 721 to the overhead fractionation tank 722 to obtain dehydrated and light component-removed oil products.

[0044]The waste engine oil recovery and reuse process in this embodiment also includes a recovery and utilization device for the tower top gas. The mixed gas of gasoline and diesel components is evaporated from the top of the flash tower, and after recovery, it is cooled, exported, separated, stored and transported, and then sold. This is another income product of waste engine oil recycling and reuse.

Embodiment 3

[0046] A waste engine oil recovery and reuse equipment, including atmospheric and vacuum distillation equipment, also includes pre-processing equipment, the pre-processing equipment includes: a storage tank 1, a crude oil pump 2, a first heat exchanger 3, a second heat exchanger 4. Vertical tubular heating furnace 5, flash tower 6, second heat exchanger 4, water cooler 712, filter 713, finished product tank 714, connecting pipes and valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com