Method for producing sodium gluconate by fermenting aspergillus niger

A fermentation technology of sodium gluconate and Aspergillus niger, which is applied in the field of bioengineering, can solve the problems of affecting the output and quality of sodium gluconate, yellowing, and smelling, and achieve the effects of shortening fermentation time, increasing yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take a piece of Aspergillus niger, scrape the upper spores, insert it into the culture medium, cultivate it at 30°C until the spores are covered, and prepare a bacterial suspension for later use; the culture medium is a modified Martin agar medium;

[0030] Add 2.0kg of pure glucose, 2.2g of bran, 2.0g of potassium dihydrogen phosphate, 2.0g of magnesium sulfate, 6.2g of diammonium hydrogen phosphate, and 2.6ml of antifoaming agent to a 15L culture tank, make up to 10L, and sterilize at 115°C 20 minutes, then drop to 36°C, add 250ml bacterial suspension, control the temperature of the seed solution to 30°C; keep the pH of the seed solution at 5.2; control the dissolved oxygen (DO) ≥ 30%, and cultivate for 20 hours.

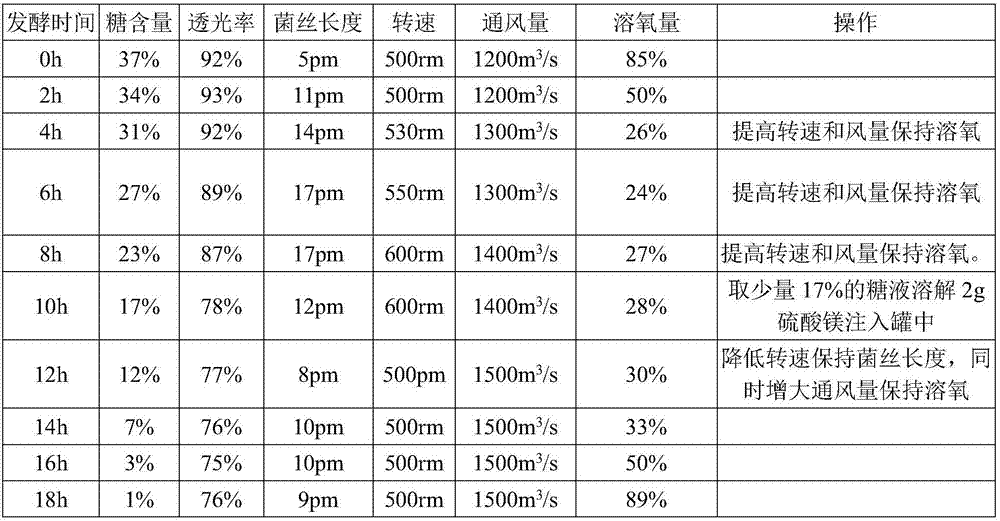

[0031]Add 5.4kg of pure glucose, 2.13g of potassium dihydrogen phosphate, 1.43g of magnesium sulfate, 1.11g of urea, 0.032g of diammonium hydrogen phosphate, and 7.02ml of defoamer to a 50L fermenter (first-level fermenter), and set the volume to 27L , ster...

Embodiment 2

[0039] Take a piece of Aspergillus niger, scrape the upper spores, insert it into the culture medium, cultivate it at 30°C until the spores are covered, and prepare a bacterial suspension for later use; the culture medium is a modified Martin agar medium;

[0040] Add 1.85kg of pure glucose, 2.1g of bran, 1.9g of potassium dihydrogen phosphate, 1.9g of magnesium sulfate, 6g of diammonium hydrogen phosphate, and 2.6ml of defoamer into a 15L culture tank, make up to 10L, and sterilize at 115°C for 20 minutes, then lowered to 36°C, added 250ml of bacterial suspension, controlled the temperature of the seed solution to 30°C; kept the pH of the seed solution at 5.2, controlled dissolved oxygen (DO) ≥ 30%, and cultivated for 20 hours.

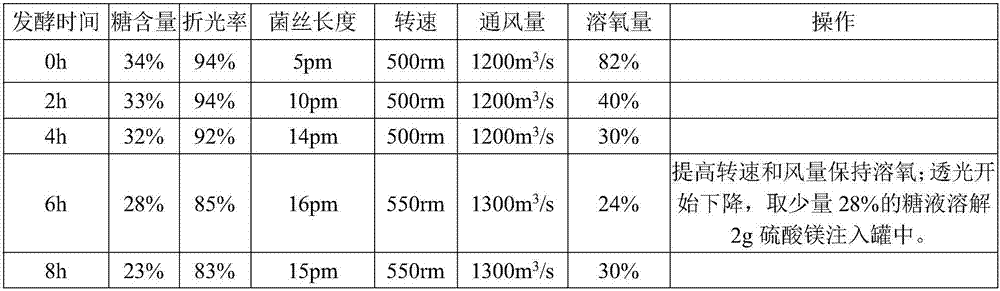

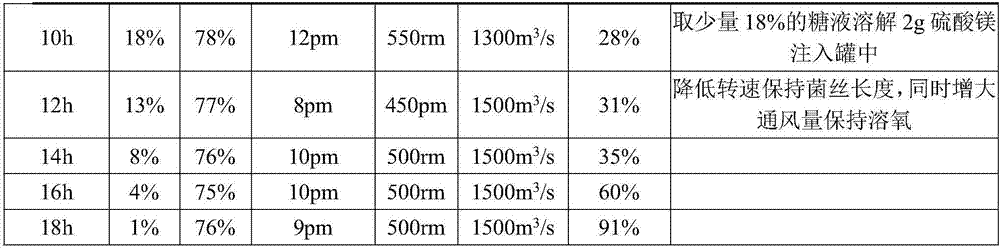

[0041] The second step, fermentation: add 5kg of pure glucose, 2.11g of potassium dihydrogen phosphate, 1.40g of magnesium sulfate, 1.08g of urea, 0.28g of diammonium hydrogen phosphate, and 7.02ml of defoamer to the 50L fermenter (first-level ferment...

Embodiment 3

[0050] Take a piece of Aspergillus niger, scrape the upper spores, insert it into the culture medium, cultivate it at 30°C until the spores are covered, and prepare a bacterial suspension for later use; the culture medium is a modified Martin agar medium;

[0051] Add 2.15kg of pure glucose, 2.4g of bran, 2.2g of potassium dihydrogen phosphate, 2.2g of magnesium sulfate, 6.4g of diammonium hydrogen phosphate, and 2.6ml of defoamer into a 15L culture tank, make up to 10L, and sterilize at 115°C 20 minutes, then drop to 36°C, add 250ml of bacterial suspension, control the temperature of the seed solution to 30°C; keep the pH of the seed solution at 5.2, control dissolved oxygen (DO) ≥ 30%, and cultivate for 20 hours.

[0052] The second step, fermentation: add 5.8kg of pure glucose, 2.06g of potassium dihydrogen phosphate, 1.46g of magnesium sulfate, 1.13g of urea, 0.38g of diammonium hydrogen phosphate, and 7.02ml of defoamer to the 50L fermenter (first-level fermenter). , dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com