Laser strengthening alloying method for railway rail

A laser strengthening and alloying technology, which is applied in the coating process and coating of metal materials, can solve the problems of wear failure, limitation, wear resistance and contact fatigue resistance, etc., so as to improve the service life and performance , the effect of extensive use of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

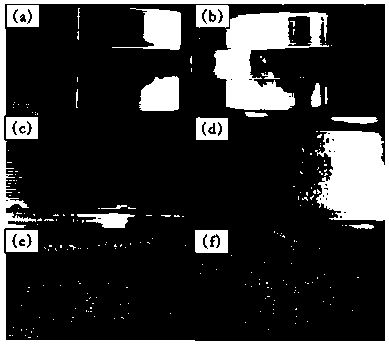

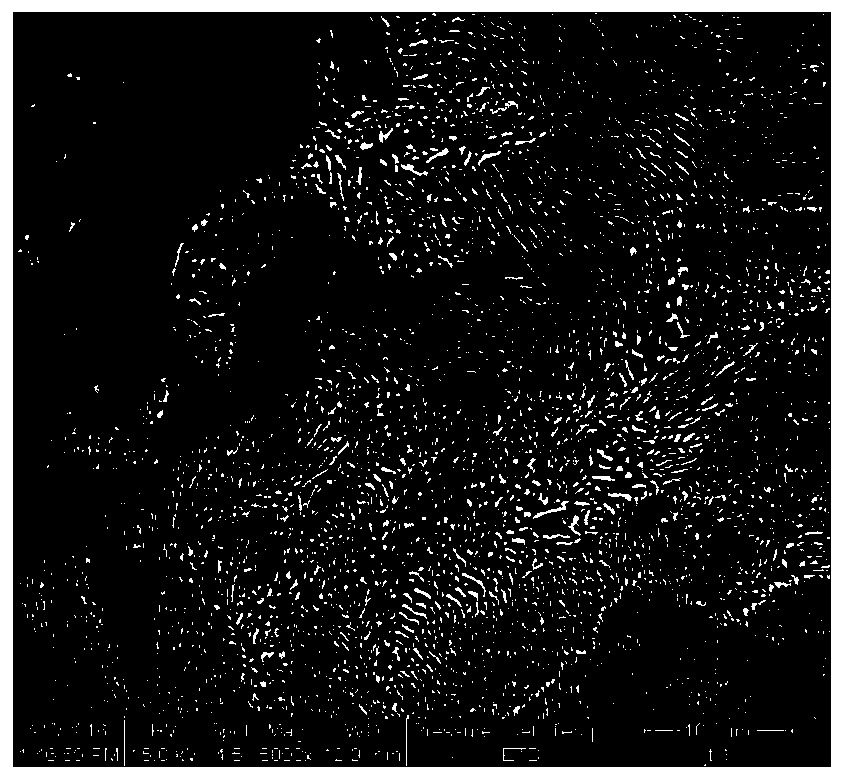

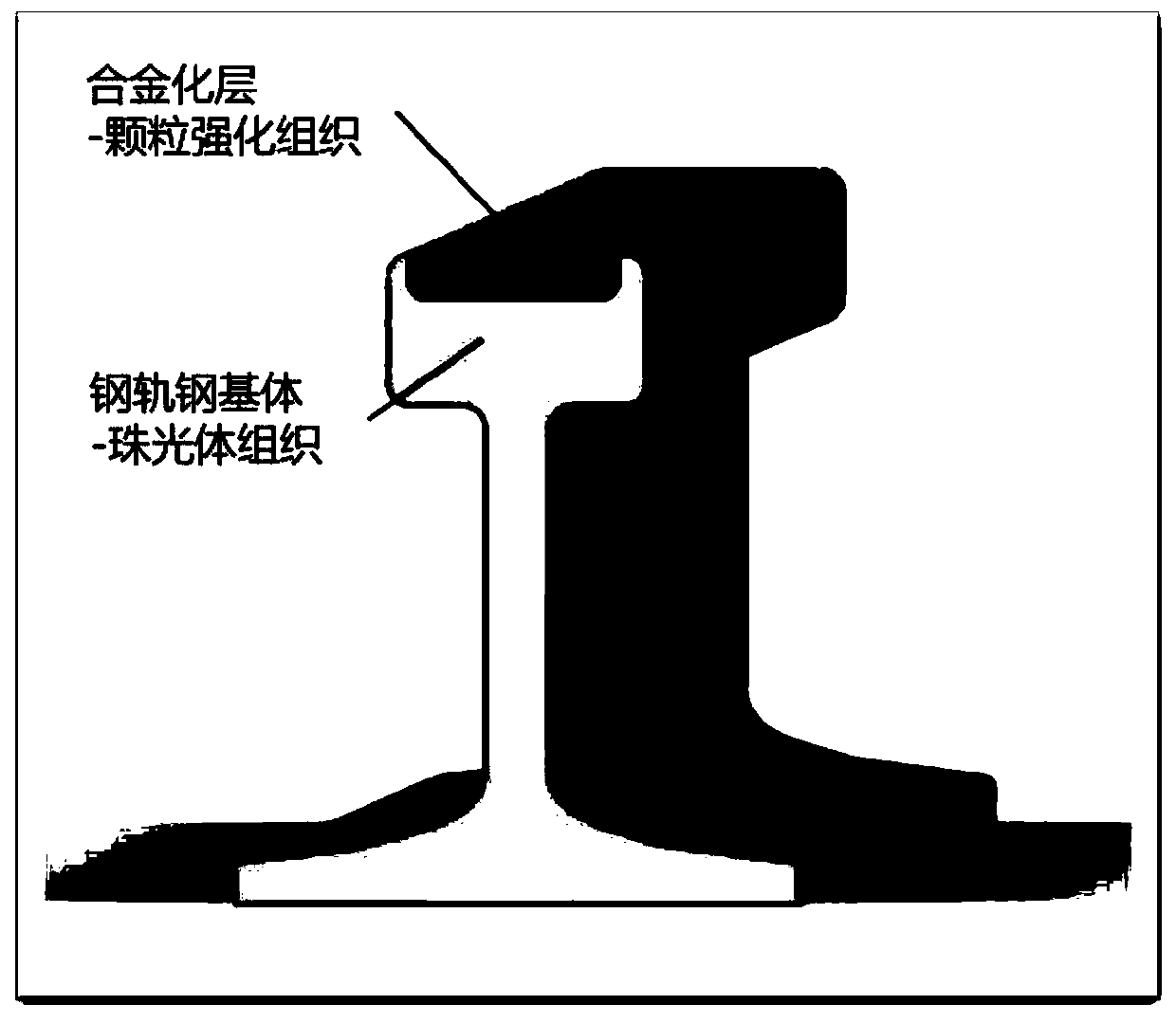

Image

Examples

Embodiment 1

[0047] (1) Inspection of the delivered rails, including rail molding dimensions, surface cracks, etc., requiring the rails to meet the rail usage standards.

[0048] (2) Clean the surface of the rail: clean the rust on the surface of the rail to make the surface of the rail free of rust, oil, etc.

[0049] (3) Spray alloying coating: use a spray gun to evenly spray the prepared alloying coating for rail laser strengthening, including 30% alloy powder, 40% alcohol and 30% binder, on the surface of the rail to be strengthened , the thickness of the coating is uniform and reaches 0.05-0.2mm; then dry it with natural wind or fan. Wherein the alloy powder is composed of the following raw materials in mass fraction: 10% Ni, 25% Cr, 30% WC, 15% Ti and 20% C.

[0050] (4) Using a high-power semiconductor laser with a power of 4000W, a circular spot with a spot diameter of 4mm is used to conduct a full-area multi-lap scan on the reinforced area of the rail after spraying. The scanni...

Embodiment 2

[0053] (1) Inspection of the delivered rails, including rail molding dimensions, surface cracks, etc., requiring the rails to meet the rail usage standards.

[0054] (2) Clean the surface of the rail: clean the rust on the surface of the rail to make the surface of the rail free of rust, oil, etc.

[0055] (3) Spray alloying coating: use a spray gun to evenly spray the prepared alloying coating for rail laser strengthening, including 40% alloy powder, 30% alcohol and 30% binder, on the surface of the rail to be strengthened , the coating thickness is uniform, and reaches 0.05-0.5mm; then dry with natural wind or fan. Wherein the mass fraction of each component constituting the alloy powder is: 15% Ni, 20% Cr, 25% WC, 20% Ti and 20% C.

[0056] (4) Utilize a high-power semiconductor laser with a power of 5000W, use a broadband light spot with a length of 2mm and a width of 25mm to scan the entire area of the sprayed rail strengthening area through one scan, and the scanning ...

Embodiment 3

[0059] (1) Inspection of the delivered rails, including rail molding dimensions, surface cracks, etc., requiring the rails to meet the rail usage standards.

[0060] (2) Clean the surface of the rail: clean the rust on the surface of the rail to make the surface of the rail free of rust, oil, etc.

[0061] (3) Spray alloying coating: use a spray gun to evenly spray the prepared alloying coating for rail laser strengthening, including 35% alloy powder, 40% alcohol and 25% binder, on the surface of the rail to be strengthened , the coating thickness is uniform, and reaches 0.1-0.5mm; then dry with natural wind or fan. Wherein the mass fractions of the components constituting the alloy powder are: 20% Ni, 25% Cr, 30% WC, 10% Ti and 15% C.

[0062] (4) Utilize a high-power semiconductor laser with a power of 6000W, and use a circular spot with a diameter of 5mm to distribute the spot on the surface of the reinforced area of the rail specimen after spraying, with a gap of 0.1-1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com