Array target of X-ray source for electron beam scanning CT and manufacturing method of array target

A technology of electron beam scanning and manufacturing method, applied in parts of X-ray tube, X-ray/γ-ray/particle irradiation therapy, etc. Charge-discharge effect, increase thermal conductivity, avoid the effect of charge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

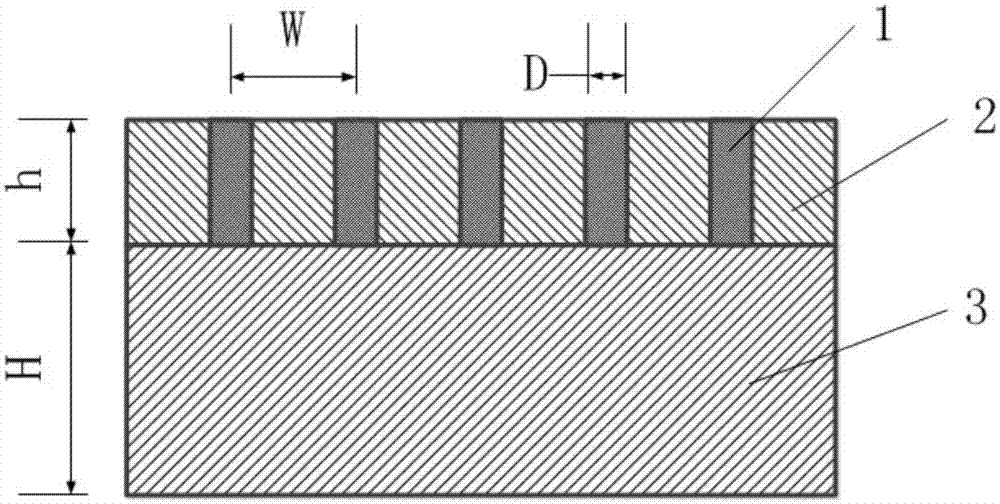

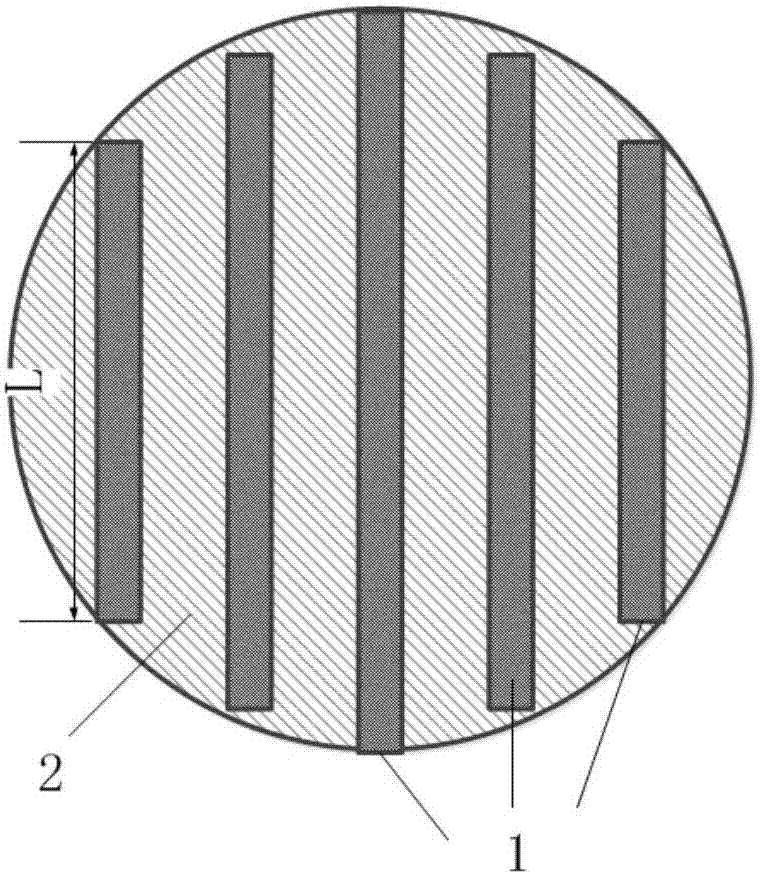

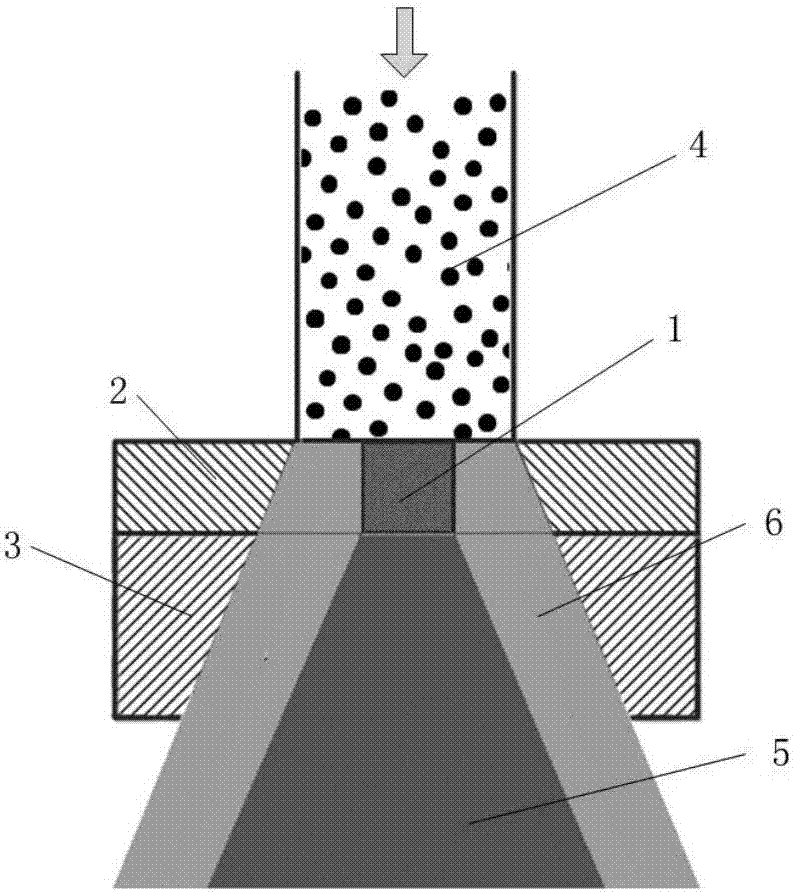

[0036] Such as figure 1 , figure 2 with image 3 As shown, an array target for an X-ray source of electron beam scanning CT, including a linear array target position, an embedding layer 2 and a target base 3;

[0037] The linear array target site includes at least one individual target site 1, the individual target site 1 is in the shape of a line, 0.5 to 10 μm deep into the embedding layer, and the two ends of the target site 1 extend to the embedding layer The edge of layer 2, its function is: the metal target is connected with the metal sealing part on the edge of the embedded layer to form a conductive channel, which is beneficial to charge transfer and avoids the charge accumulation (charging effect) caused by the electron beam. The width of the target position 1 / 2 to 2 / 3 of the diameter of the electron beam; several target positions 1 form a linear array target position;

[0038] The embedding layer 2 is used to configure the target site 1;

[0039] The target base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com