Preparation method of enhanced GaN HEMT

An enhanced and p-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as leakage, damage interface, and affect device stability, so as to reduce gate leakage, reduce interface state, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Those skilled in the art can make similar extensions without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

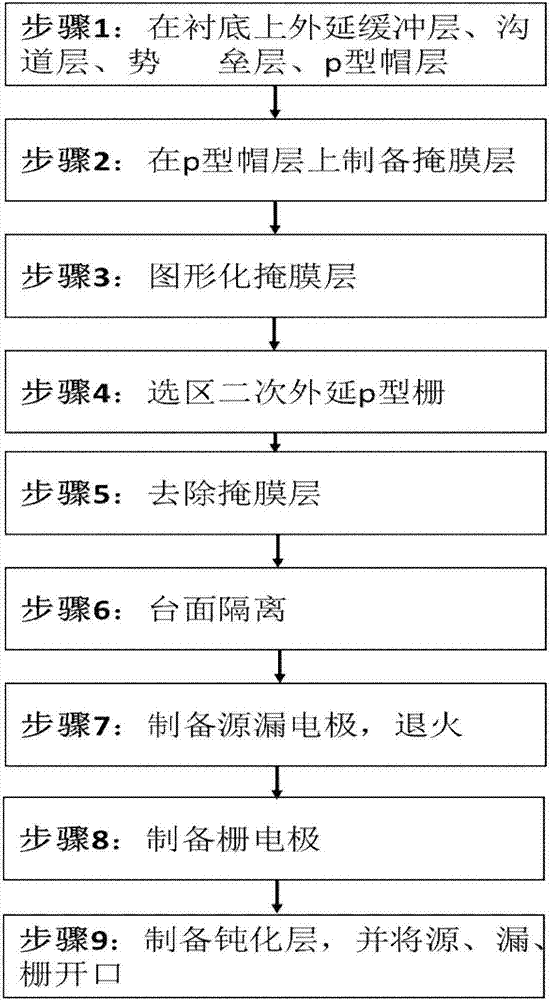

[0028] see figure 1 , Figure 2-Figure 9 As shown, according to the general inventive concept of the present invention, a method for preparing an enhanced GaN HEMT is provided, comprising the following steps:

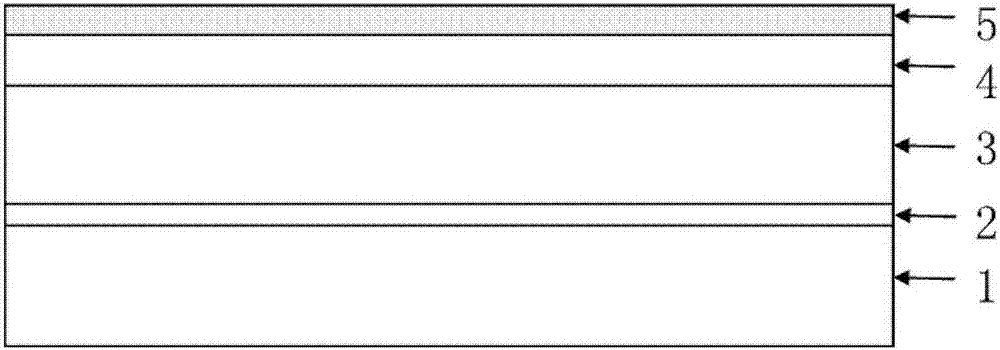

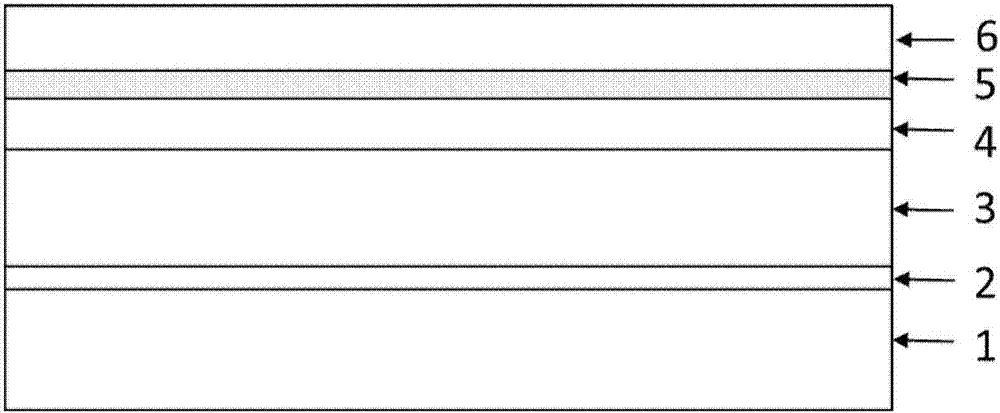

[0029] Step 1: Epitaxial buffer layer 2, channel layer 3, barrier layer 4 and p-type cap layer 5 are sequentially epitaxial on substrate 1 by metalorganic chemical vapor deposition, and the material of substrate 1 is Si, sapphire, SiC or GaN, the buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com