Production system and production method for hard Chinese yam capsule

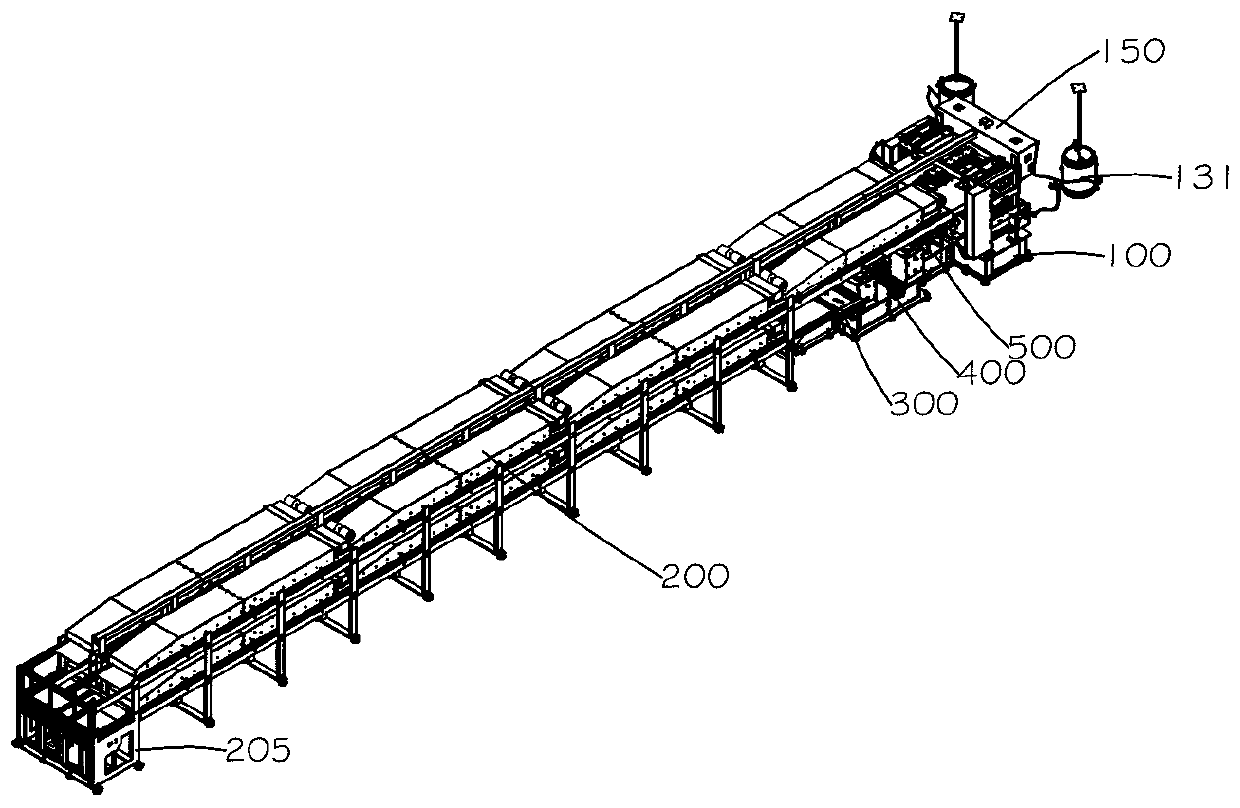

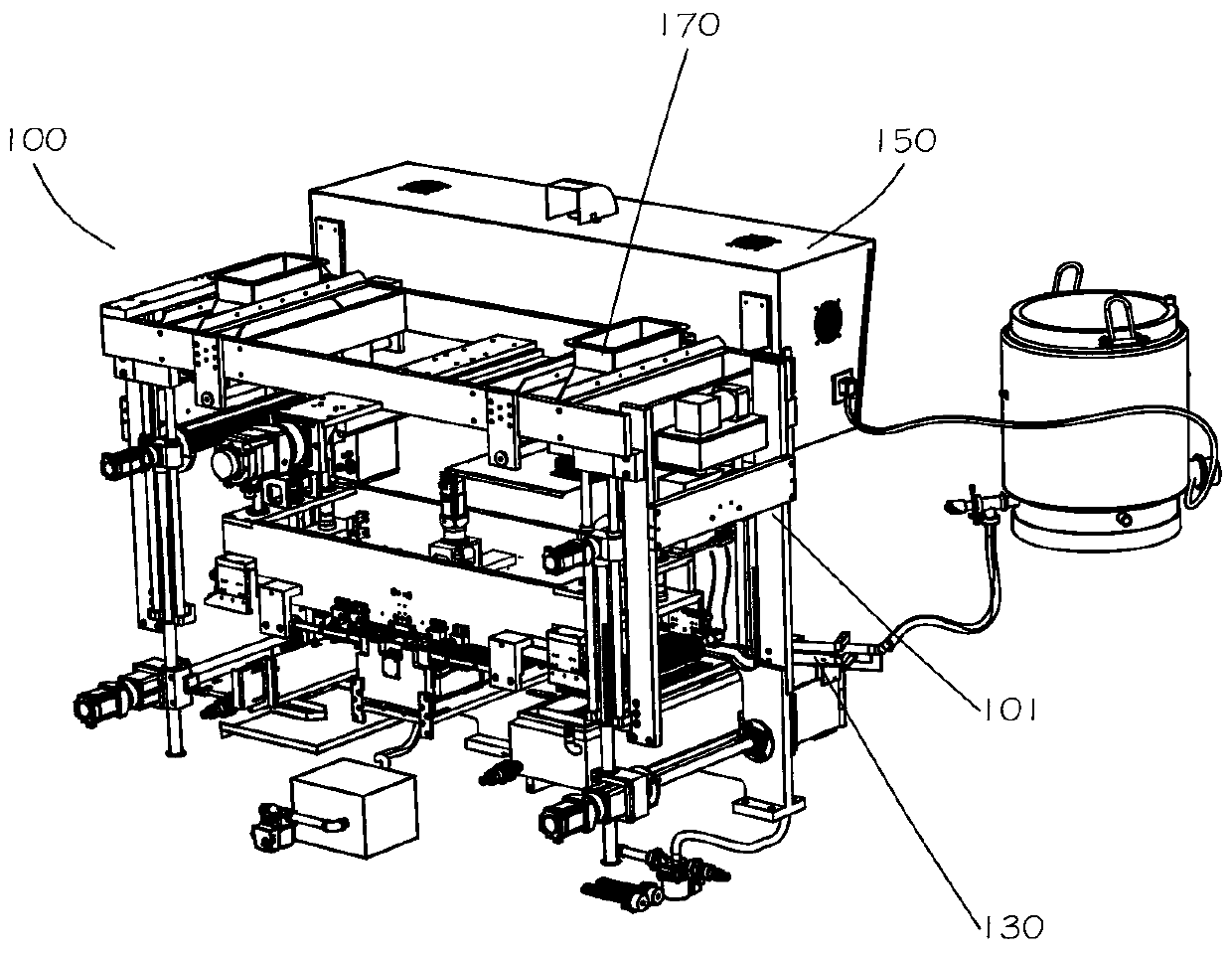

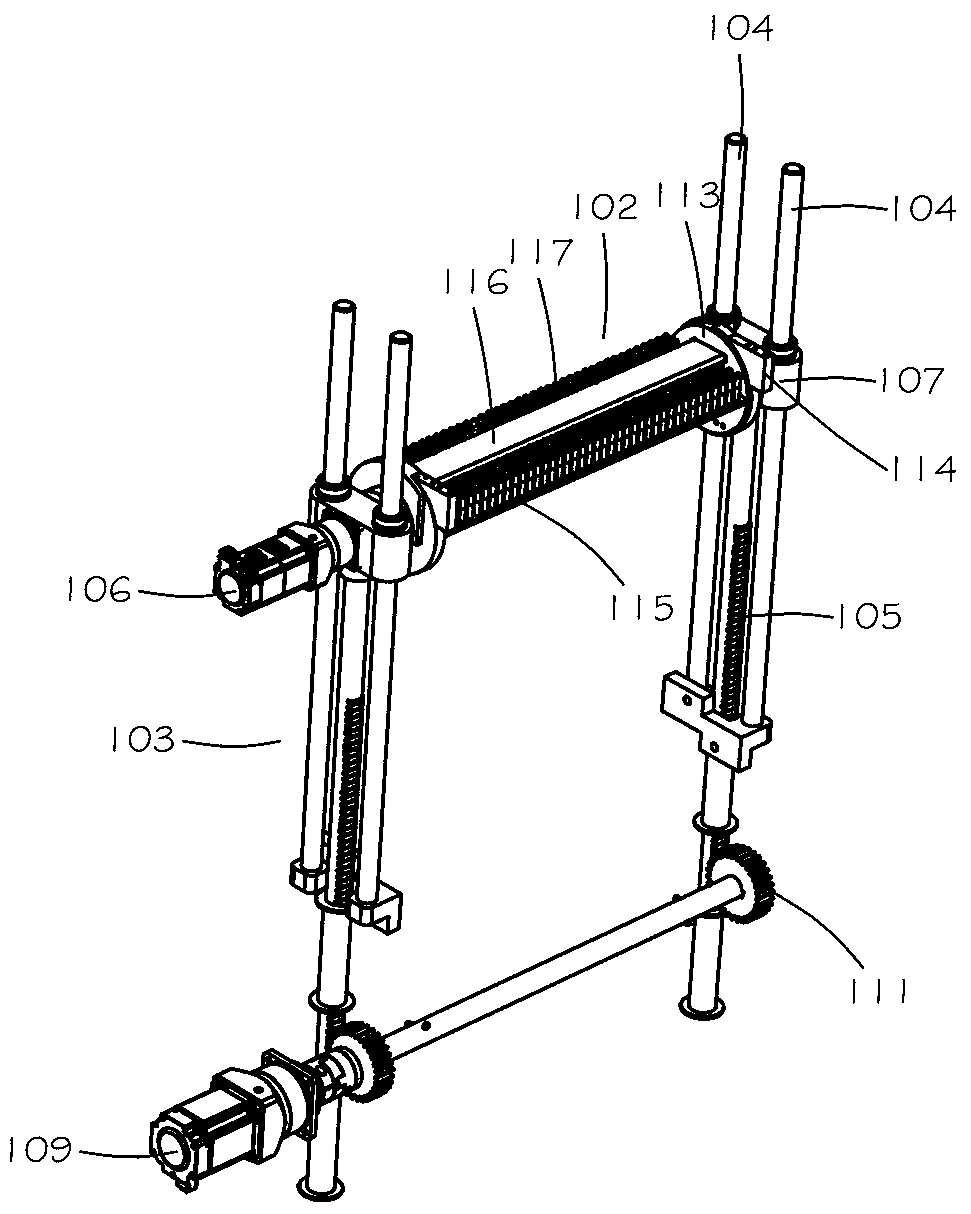

A capsule production system and production system technology, which are applied in the functions of food ingredients, food ingredients containing natural extracts, food drying, etc., can solve the problems of low work efficiency and slow speed, and achieve high work efficiency and fast dipping speed. , good for digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the examples.

[0040] Chinese yam hard capsule of the present invention, by weight percentage, by gelatin 24.5%, magnesium stearate 3%, 65% ethanol 31.3%, calcium carbonate 7%, triethyl citrate 2%, sorbitol 1%, glycerin 3.0%, 0.06% methyl p-hydroxybenzoate, 1.2% titanium dioxide, 1.2% methyl silicone oil and the rest of yam extract. Consists of 0.2% pectin, sodium sulfite, and sodium chloride. The yam mucilage is prepared by the following steps: the yam is made into a slurry, the supernatant is taken after centrifugation, the sediment is added with water and stirred, and the washing liquid is obtained by centrifugation again to remove the sediment, the washing liquid and the supernatant are mixed, and the yam mucilage is obtained by vacuum concentration. .

[0041] The production method of the yam hard capsule of the present invention comprises: preparing materials, respectively measuring gelat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com