An interlayer mixing device for artificial stone slab texture processing

A mixing device and artificial stone slab technology, which is applied in stone processing equipment, stone processing tools, liquid ingredient supply devices, etc., can solve the problem that the texture effect of natural stone is very different, the texture effect is single, and the texture effect of multiple colors cannot be realized, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

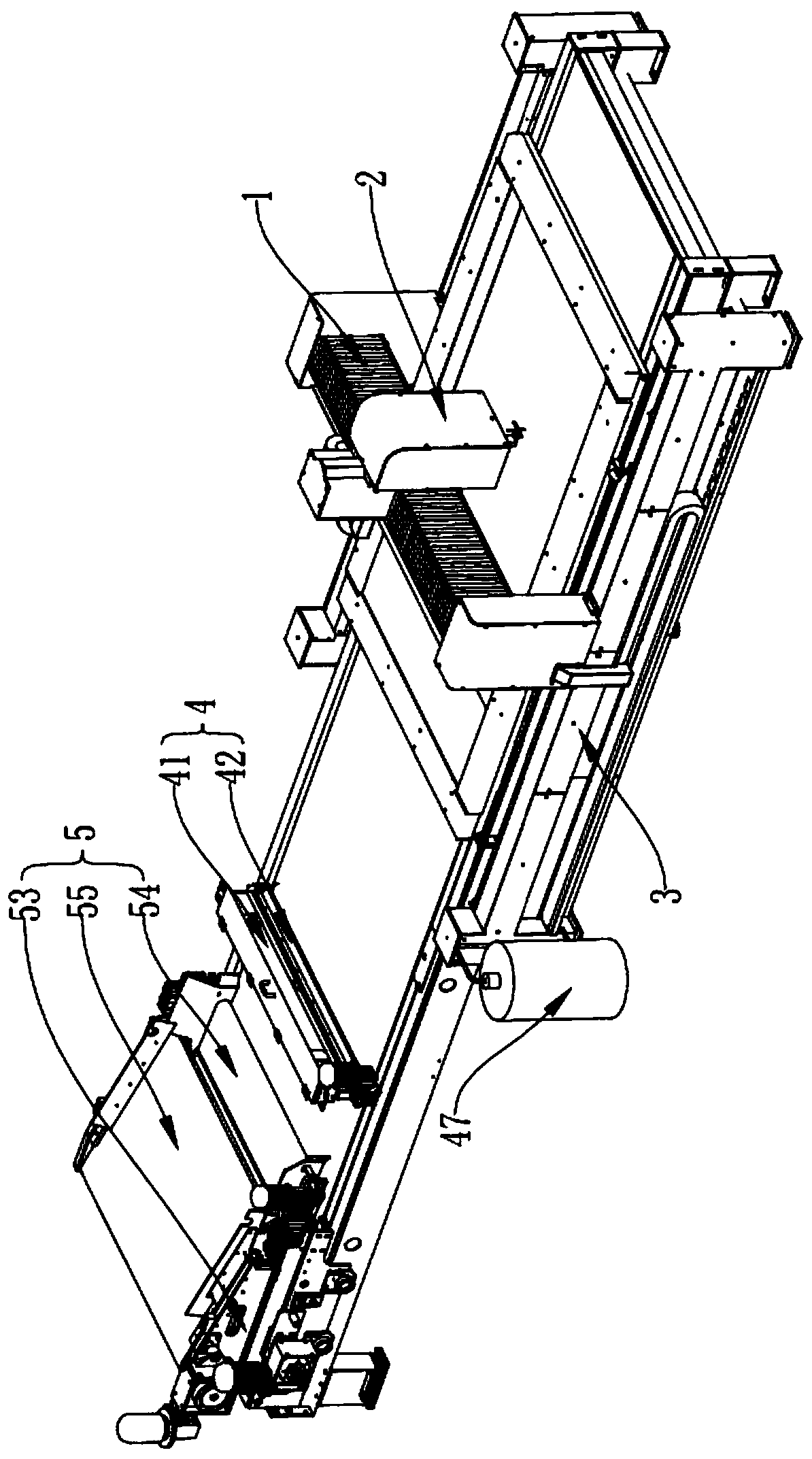

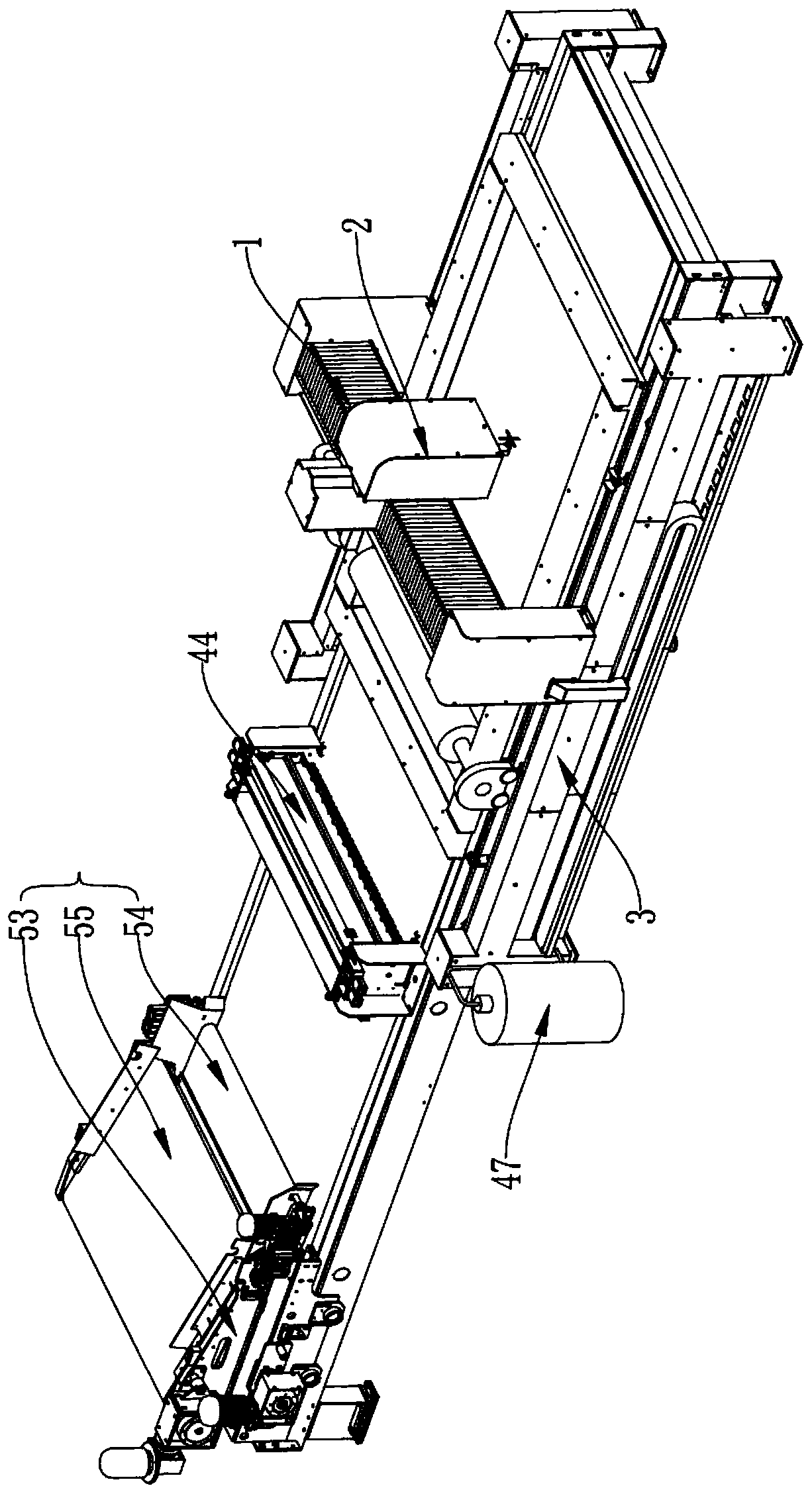

[0054] Such as figure 1 and figure 2 As shown, the pressing material component 5 and the stirring component 2 are relatively independently arranged at two stations, and the dispensing color material component 4 is working when the sheet material that has been applied with extrusion force enters the stirring component 2 Apply color to the surface of the sheet prior to the area.

[0055] Set the pressing component 5 and the stirring component 2 on two relatively independent stations, and the sheet material passes through the working areas of the two components in order to complete the corresponding processing technology, and relatively set the two components on the same station to complete , can reduce the time that the sheet stays at one station, that is, reduce the waiting time for the next sheet processing, compact the process flow of the product, and improve production efficiency; in addition, at a relatively independent station, it can be processed according to the proces...

Embodiment 2

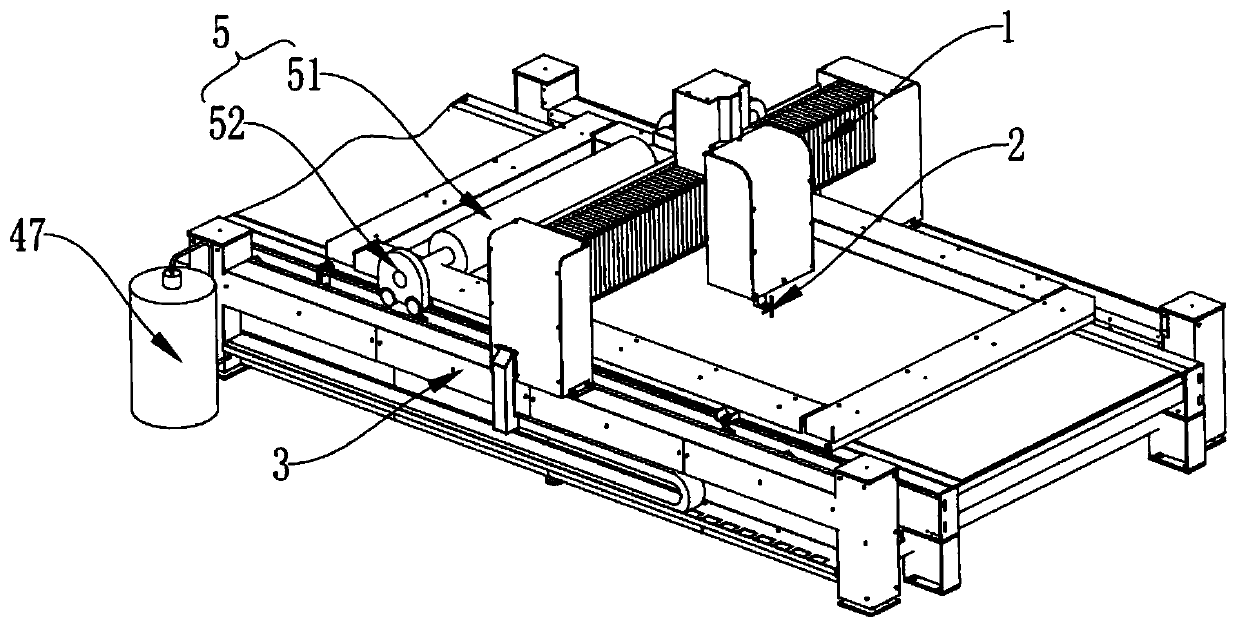

[0066] Such as image 3 As shown, in this embodiment, the distributing colorant component 4 and the stirring component 2 can be set at the same station.

[0067] In this embodiment, the process of distributing the coloring material and stirring is completed at the same station, and the compaction components can also be set at the same station, or can be set at another station relatively independently, which reduces the number of sheets in the same station. Transfer steps between different processes, thus saving time.

[0068] One of the corresponding dispensing methods of distributing coloring material components in this embodiment (i.e. the third embodiment of distributing coloring material components) is carried out in the way of XYZ axis moving and dusting, which is arranged on the moving component 1, And together with the stirring assembly 2, it is moved by the moving assembly 1; the dispensing color material assembly 4 includes a color material spray head and a color sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com