Production device utilizing salt cakes to produce refined brine and byproduct (dihydrate gypsum) and production method thereof

A technology of dihydrate gypsum and purified brine, applied in the direction of calcium/strontium/barium sulfate, alkali metal halide purification, etc., can solve the problem of increase of by-product salt mud, etc., and achieves beneficial modification, uniform crystal particles, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

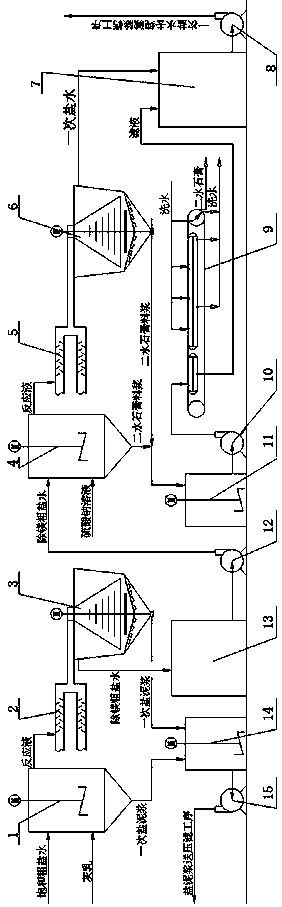

[0022] A production device that utilizes Glauber's salt to refine brine and produce dihydrate gypsum as a by-product, see the attached figure, in the figure: 1-magnesium removal reactor, 2-baffle tank I, 3-magnesium removal clarification tank, 4-calcium removal reactor , 5-baffle tank II, 6-decalcification clarification tank, 7-primary brine buffer tank, 8-primary brine pump, 9-belt filter, 10-dihydrate gypsum slurry pump, 11-dihydrate gypsum slurry Buffer barrel, 12-magnesium removal coarse brine pump, 13-magnesium removal coarse brine buffer barrel, 14-primary salt mud buffer barrel, 15-primary salt mud pump.

[0023] The magnesium removal reactor 1 is connected to the baffle tank I2 through pipelines, the baffle tank I2 is connected to the magnesium removal clarification tank 3, and the bottoms of the magnesium removal reactor 1 and the magnesium removal clarification tank 3 are respectively connected to the primary salt mud buffer tank 14 through pipelines connection, the ...

Embodiment 2

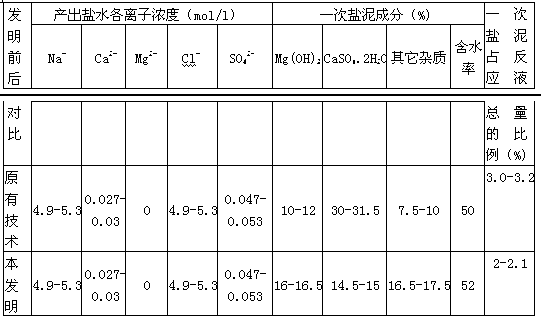

[0032] Mg in crude brine 2+ : OH in milk of lime - The molar ratio of 1:2.16 is added to the magnesium removal reactor 1 with crude brine and milk of lime, and the magnesium removal reaction is carried out under stirring conditions. The Mg in the crude brine 2+ All with OH in milk of lime - combined into Mg(OH) 2 , at the same time, there is 10% molar ratio of Ca in the reaction solution 2+ with SO 4 2- combined into CaSO 4 .2H 2 O. Mg(OH) formed in Mg removal reactor 1 2 , CaSO 4 .2H 2 O, biological slime in crude brine and water-insoluble matter in milk of lime. Mg(OH) in primary salt mud composition 2 Accounting for 16% by mass, CaSO 4 .2H 2 O accounts for 14.5%, biological slime in crude brine and water-insoluble matter in milk of lime are other impurities accounting for 16.5%, and the moisture content is 52%.

[0033] A small part of the primary salt mud settles to the bottom of the magnesium removal reactor 1 and the solution after the reaction is dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com