Process and device for integrated denitrification, carbon and phosphorus removal for advanced treatment of printing and dyeing wastewater

A printing and dyeing wastewater, advanced treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve high operating costs, serious secondary pollution, secondary biochemical It is difficult for the effluent to meet the high standard discharge requirements and other problems, so as to solve the effect of long process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

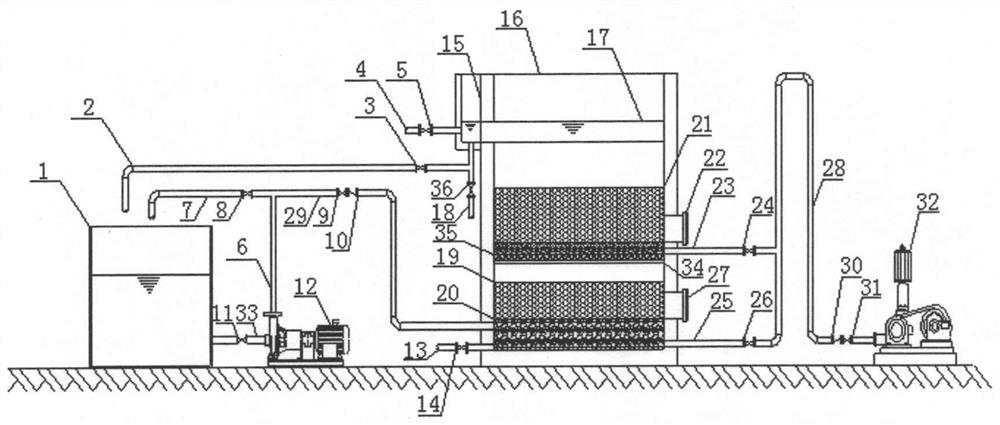

[0027] like figure 1 As shown, it is an integrated denitrification, carbon and phosphorus removal device for advanced treatment of printing and dyeing wastewater provided by the present invention. 33 is provided with water inlet pump inlet pipe regulating valve 11, and water inlet pump outlet pipe 6 communicates with return pipe 7, filter pond water inlet pipe 29 at the bottom of filter pond 16 respectively, and return pipe 7 is provided with return pipe regulating valve 8, and filter pond inlet Water pipe 29 is provided with filter tank water inlet regulating valve 9, filter tank water inlet pipe check valve 10, and the top of filter tank 16 is provided with water outlet sump 17, and outlet water sump 17 is communicated with the main outlet channel 15 on one side thereof, and the outlet main The bottom of the canal 15 is respectively communicated with the water outlet pipe 4, the backwash drain pipe 18, and the nitrification liquid return pipe 2. The outlet pipe 4 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com