A method for wastewater denitrification based on photoelectric catalysis-autotrophic biofilm

A technology of photoelectric catalysis and treatment method, applied in the fields of energy waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of low construction and operation costs, small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

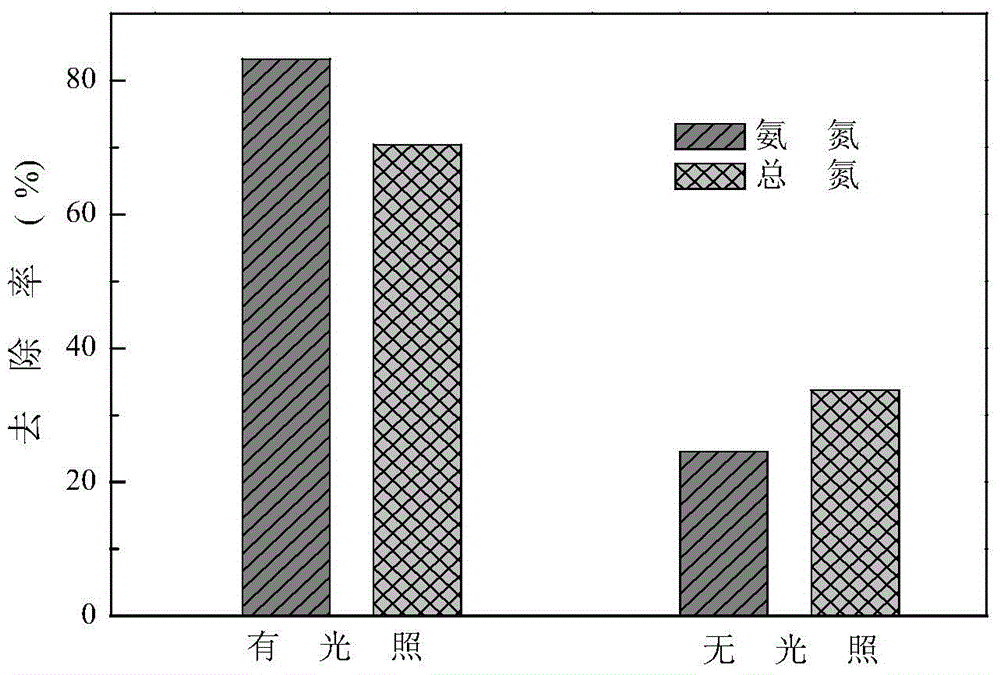

[0052] In this embodiment, the ammonia nitrogen concentration in the waste water to be treated is 35 mg / L, and the nitrate nitrogen concentration is 20 mg / L.

[0053] When carrying out denitrification treatment, first adjust the pH of the wastewater to be treated to 8, and then pass it into two reaction chambers, and completely immerse the photoanode and cathode; in addition, for the convenience of comparison, the wastewater passed into the two reaction chambers same amount. Respectively, as for the light conditions in each reaction chamber (the light intensity at a distance of 10 cm from the light source is 90 mW / cm 2 ) and no light conditions, and a working voltage of 3V was applied to the cathode and anode in each reaction chamber, so that the rotating speed of the stirring paddle was 100 rpm.

[0054] Get the ammonia nitrogen concentration and the nitrate nitrogen concentration in the waste water after reacting 12h and analyze, the result is as follows figure 1 As shown,...

Embodiment example 2

[0057] To study the effect of pH value on the denitrification effect of the reaction chamber, the concentration of ammonia nitrogen in the influent is 35mg / L, the concentration of nitrate nitrogen in the influent is 20mg / L, and there is light (the light intensity at a distance of 10cm from the light source is 90mW / cm 2 ), the applied voltage is 3V, and under the reaction conditions of stirring (the rotating speed of the stirring paddle is 100 rpm), the pH value of each reaction chamber is 6, 7, 7.5, 8 and 9. After the reaction was carried out for 12 hours, the concentration of total nitrogen in each reaction chamber was measured respectively.

[0058] The measurement results Figure 4 As shown, it can be seen that the denitrification efficiency of the reaction chamber is not high under acidic and neutral environments; under the weakly alkaline environment with pH values of 7.5 and 8, the denitrification efficiency of the reaction chamber is significantly increased. But when...

Embodiment example 3

[0060] To study the influence of the applied voltage value on the denitrification effect of the reaction chamber, the concentration of ammonia nitrogen in the influent is 35mg / L, the concentration of nitrate nitrogen in the influent is 20mg / L, and there is light (the light intensity at a distance of 10cm from the light source is 90mW / cm 2 ), the pH value is 8, and under the reaction conditions of stirring (the rotating speed of the stirring paddle is 100 rpm), the applied voltages of each reaction chamber are 0, 1, 2 and 3V. After the reaction was carried out to 12h, the concentration of total nitrogen in each reaction chamber was measured respectively, and the measurement results were as follows: Figure 5 shown.

[0061] Depend on Figure 5 It can be seen that when the applied voltage is 0-3V, the denitrification efficiency of the reaction device increases with the increase of the applied voltage, but when it is further increased to 4V, the denitrification efficiency of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com