Preparation process for quartz stone with long-acting organic antibacterial performance

A preparation process, the technology of organic antibacterial agent, applied in the field of quartz stone preparation process, can solve the problems of unsafe exudate, poor matrix compatibility, short action time, etc., achieve obvious antibacterial effect, overcome poor compatibility, step simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

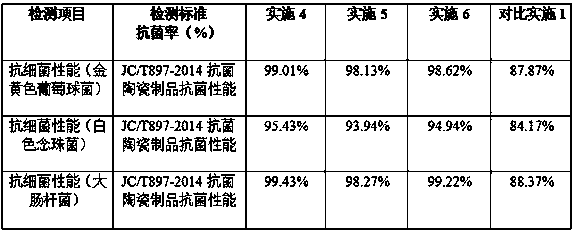

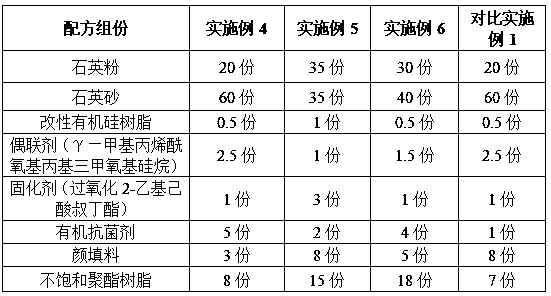

Examples

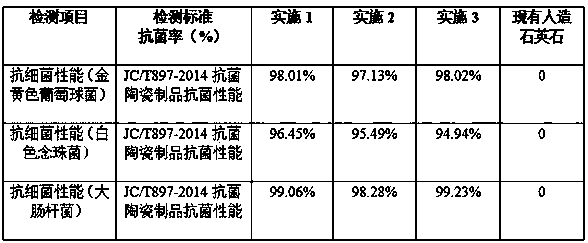

Embodiment 1

[0024] Example 1-A preparation process of organic long-acting antibacterial quartz stone, including the following steps:

[0025] (1) Weigh the following components according to the formula: 25 parts of quartz powder, 46 parts of quartz sand, 1 part of modified silicone resin, 2 parts of coupling agent, 2 parts of curing agent, 3 parts of organic polymer antibacterial agent, pigments and fillers 6 parts and 15 parts of unsaturated polyester resin;

[0026] (2) After heating the unsaturated polyester resin to 30°C, add γ-methacryloxypropyltrimethoxysilane and organic antibacterial agent, mix them together, enter the high-speed disperser and stir at high speed for 16 minutes, and polymerize to form organic Macromolecule antibacterial resin preformed liquid;

[0027] (3) Add tert-butyl peroxide 2-ethylhexanoate, pigments and fillers to the organic polymer antibacterial resin preformed liquid, mix them into a beating machine, and grind into a colored organic polymer antibacterial adhesi...

Embodiment 2

[0030] Example 2-A preparation process of organic long-acting antibacterial quartz stone, including the following steps:

[0031] (1) Weigh the following components according to the formula: 25 parts of quartz powder, 46 parts of quartz sand, 1 part of modified silicone resin, 2 parts of coupling agent, 2 parts of curing agent, 3 parts of organic polymer antibacterial agent, pigments and fillers 6 parts and 15 parts of unsaturated polyester resin;

[0032] (2) After heating the unsaturated polyester resin to 50°C, add γ-methacryloxypropyltrimethoxysilane and organic antibacterial agent, mix them together, enter the high-speed disperser and stir at high speed for 14 minutes, and polymerize to form organic Macromolecule antibacterial resin preformed liquid;

[0033] (3) Add tert-butyl peroxide 2-ethylhexanoate, pigments and fillers to the organic polymer antibacterial resin preformed liquid, mix them into a beating machine, and grind into a colored organic polymer antibacterial adhesi...

Embodiment 3

[0036] Example 3-A preparation process of organic long-acting antibacterial quartz stone, including the following steps:

[0037] (1) Weigh the following components according to the formula: 25 parts of quartz powder, 46 parts of quartz sand, 1 part of modified silicone resin, 2 parts of coupling agent, 2 parts of curing agent, 3 parts of organic polymer antibacterial agent, pigments and fillers 6 parts and 15 parts of unsaturated polyester resin;

[0038] (2) After heating the unsaturated polyester resin to 40°C, add γ-methacryloxypropyltrimethoxysilane and organic antibacterial agent, mix them together, enter the high-speed disperser and stir at high speed for 15 minutes, and polymerize to form organic Macromolecule antibacterial resin preformed liquid;

[0039] (3) Add tert-butyl peroxide 2-ethylhexanoate, pigments and fillers to the organic polymer antibacterial resin preformed liquid, mix them into a beating machine, and grind into a colored organic polymer antibacterial adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com