Process using grinding-aid-free wet grinding and slurry grading to prepare superfine ground calcium carbonate

A technology of heavy calcium carbonate and slurry, applied in calcium carbonate/strontium/barium, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve problems such as narrow particle size distribution, simplify process, reduce cost, and improve application safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The production system adopted in the preparation process of the present invention includes a raw material tank 1, a batching tank 2, a wet mill 3, a cyclone 4, a finished product slurry tank 5, a centrifuge 6, a dryer 7, a finished product tank 8, Packing Machine. The cyclone 4 is a hydrocyclone; the hydrocyclone includes an overflow port and an underflow port. A wet mill buffer tank 10 is arranged between the batching tank 2 and the wet mill 3 ; a cyclone feed tank 11 is arranged between the wet mill 3 and the cyclone 4 .

[0038] As an improvement, a wet grinder buffer tank 10 is also arranged between the batching tank 2 and the wet grinder 3, and the outlet of the batching tank 2 is connected to the wet grinder buffer tank 10, and the wet grinder buffer tank 10 It is connected with the feeding port of the wet mill 3 . The slurry in the batching tank 2 is delivered to the buffer tank 10 of the wet mill through the batching tank discharge pump. The slurry pump and t...

Embodiment 1

[0041] A process for preparing superfine ground calcium carbonate by wet grinding without grinding aids and grading slurry, comprising the following steps:

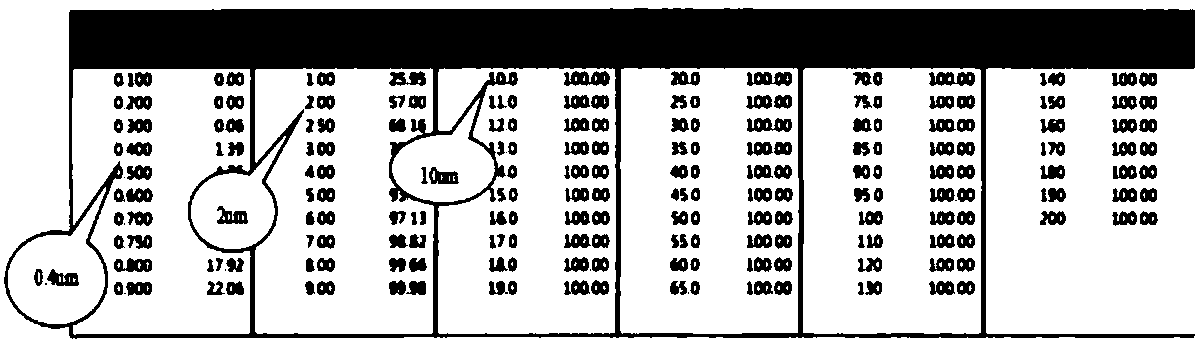

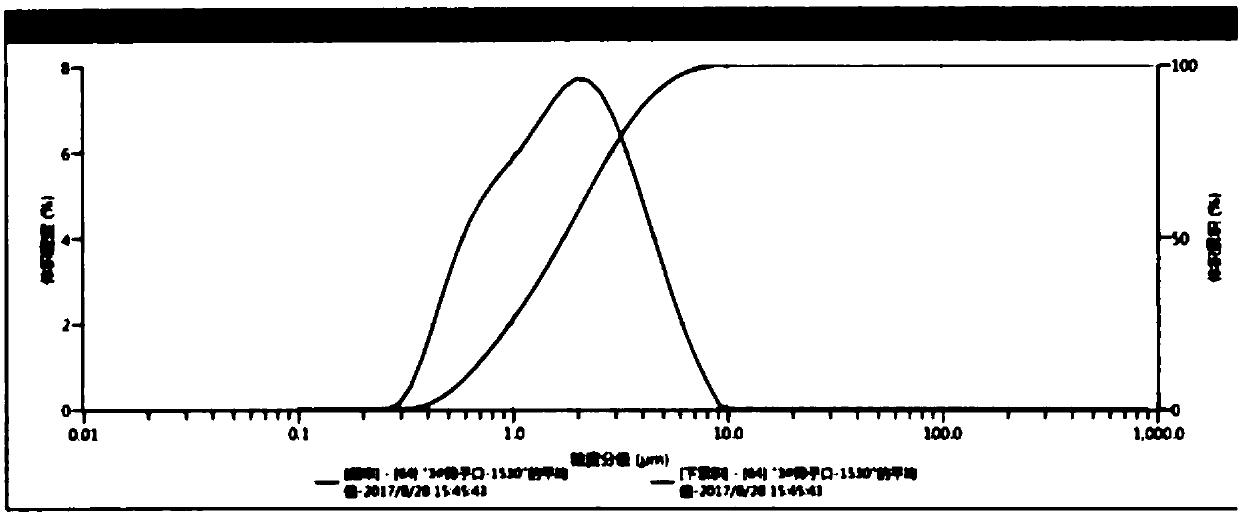

[0042] S1. Slurry preparation: Calcite (calcium carbonate (dry basis) 99.33%; hydrochloric acid insolubles 0.024%; reducing sulfur ≤ 5mg / kg; sulfide-free; Fe 0.002%; Fe 46mg / kg; As3mg / kg; heavy metal (0.001% in terms of lead)) is crushed by a crusher and pulverized into coarse powder by a grinder, and stored in the raw material tank 1 for subsequent use. The decomposed stone coarse powder is transported in the batching tank 2 by screw conveyor then, and adds water and prepares slurry, and the slurry solid content of configuration is 35%. Finally, the slurry is quantitatively delivered to the wet mill 3 through a horizontal centrifugal slurry pump and a flow meter for grinding; the wet mill feeds 2 tons, and the power per ton is 60KW. Slurry particle size after grinding 2um 41%, D 50 =2.70,D 97 =10.6, +25um>30ppm.

[004...

Embodiment 2

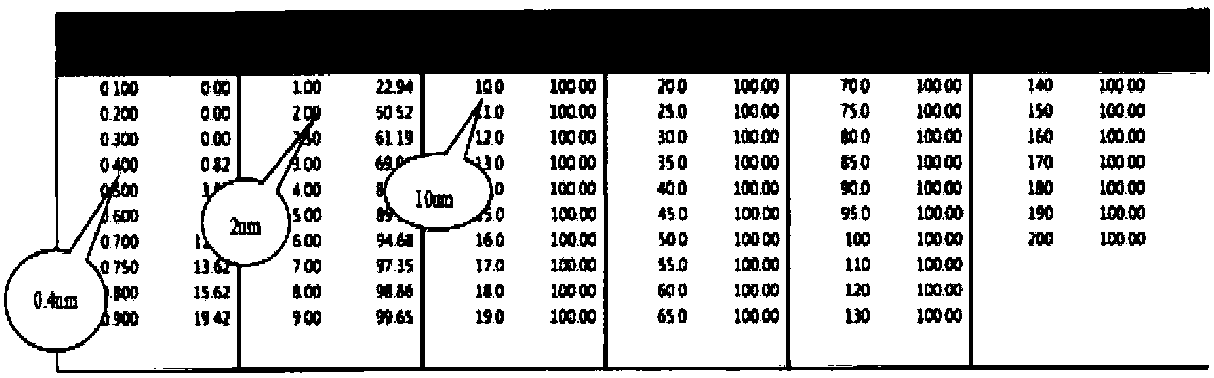

[0049] A process for preparing superfine ground calcium carbonate by wet grinding without grinding aids and grading slurry, comprising the following steps:

[0050] S1. Slurry preparation: Calcite (calcium carbonate (dry basis) 99.33%; hydrochloric acid insolubles 0.024%; reducing sulfur ≤ 5mg / kg; sulfide-free; Fe 0.002%; Fe 46mg / kg; As3mg / kg; heavy metal (0.001% in terms of lead)) is crushed by a crusher and pulverized into coarse powder by a grinder, and stored in the raw material tank 1 for subsequent use. The decomposed stone coarse powder is transported in the batching tank 2 by screw conveyor then, and adds water and prepares slurry, and the slurry solid content of configuration is 32%. Finally, the slurry is quantitatively delivered to the wet mill 3 by a horizontal centrifugal slurry pump and a flow meter for grinding; the wet mill feeds 1.6 tons, the ton power is 85KW, and the flow rate of the grinder for grinding is 110L / min. Slurry particle size after grinding 2um ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com