Preparation method of beta crystal form silodosin

A technology of silodosin and β crystal form, which is applied in the field of preparation of silodosin β crystal form, can solve the problems of increased silodosin oxidized impurities, high scale-up production cost, low crystallization yield, etc., and achieves product High yield, easy operation, guaranteed high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

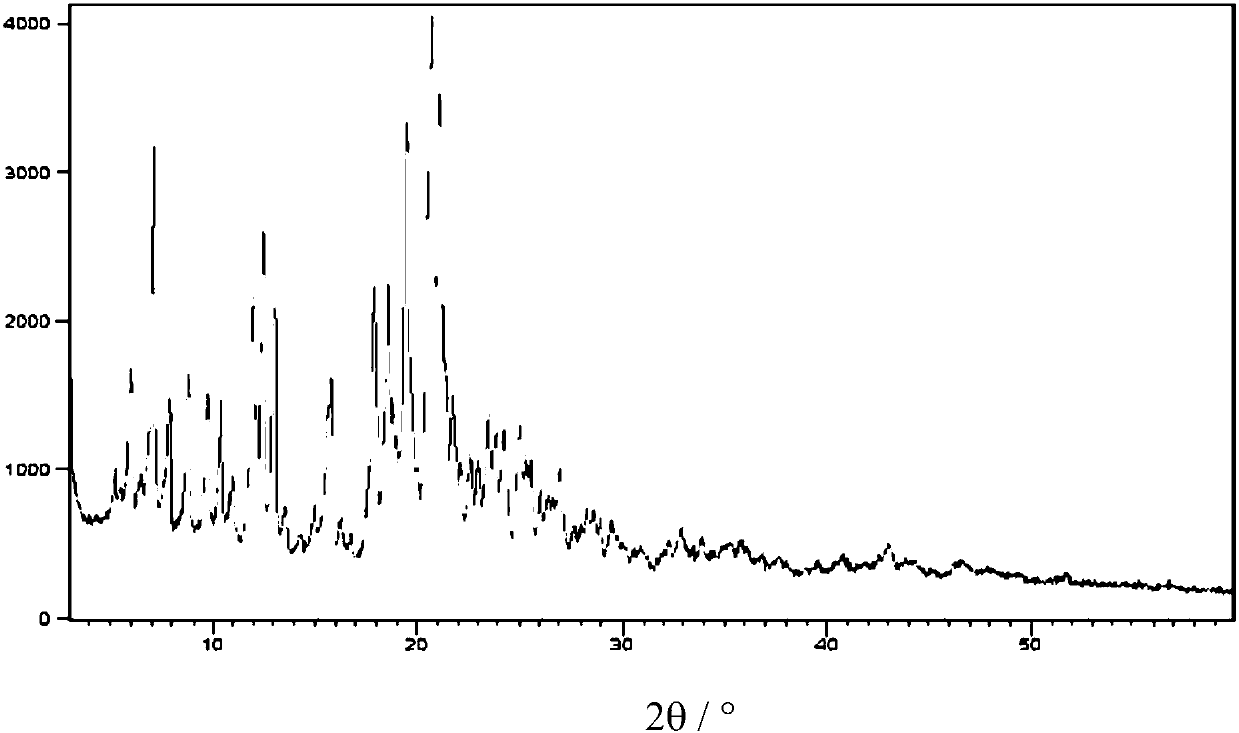

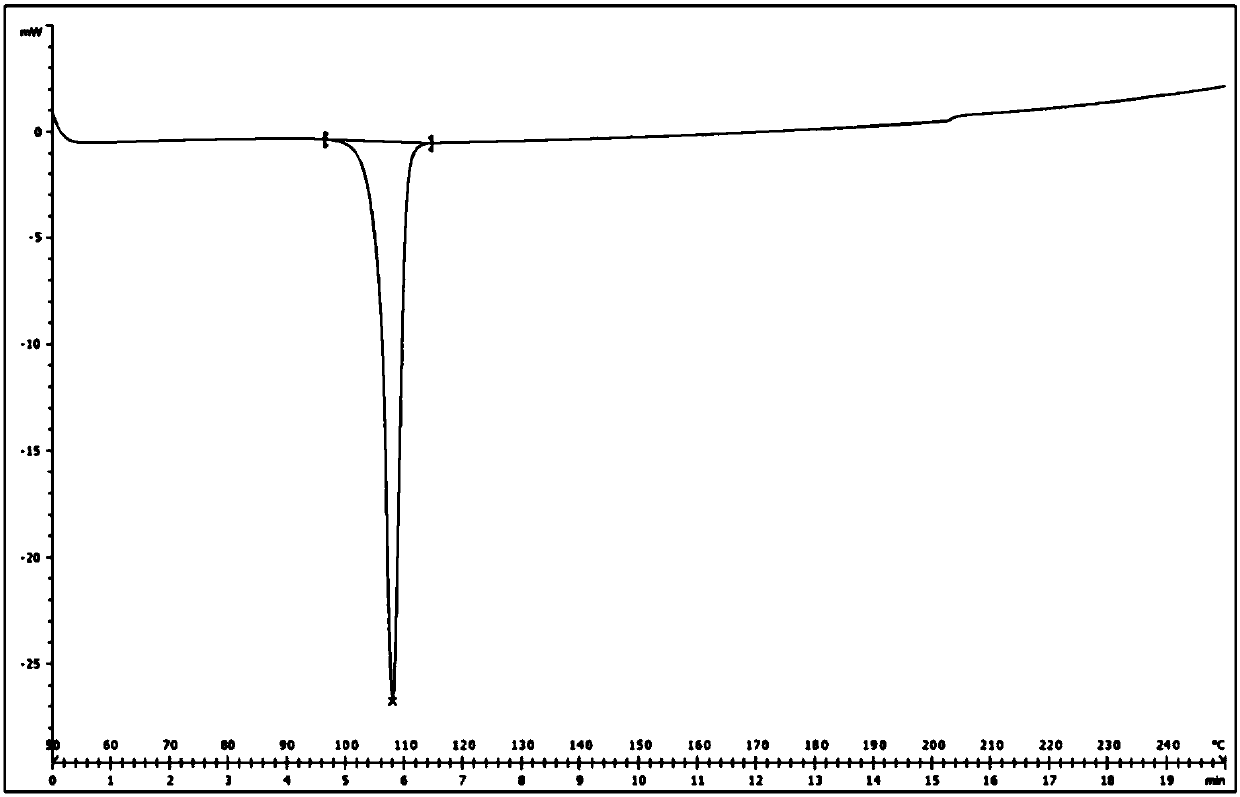

[0046] Under the protection of nitrogen, add 10g of silodosin and 50mL of isopropanol into the three-necked flask, stir, raise the temperature to 50-60°C, and keep it warm for 1 hour. The silodosin is completely dissolved. Slowly drop it into 50mL of n-heptane preheated to 50-60°C, keep stirring the crystallization feed liquid for 2 hours after dropping, then control the cooling rate at 10°C / hour, and cool the feed liquid to 0-10°C , heat preservation and crystallization for 2 hours, filter under nitrogen protection, wash the crystals with a small amount of n-heptane, and vacuum-dry the gained crystals to obtain silodosin in β crystal form of 8.8g, with a yield of 88%. The XRD detection spectrum results of the samples are shown in the attached figure 2 As shown in table 2, the DSC detection spectrum result of sample is as attached image 3 As shown, the crystal melting range is 105.31°C-106.95°C.

[0047] Table 2 Comparison Table of Main 2θ Diffraction Angles in XRD Detectio...

Embodiment 2

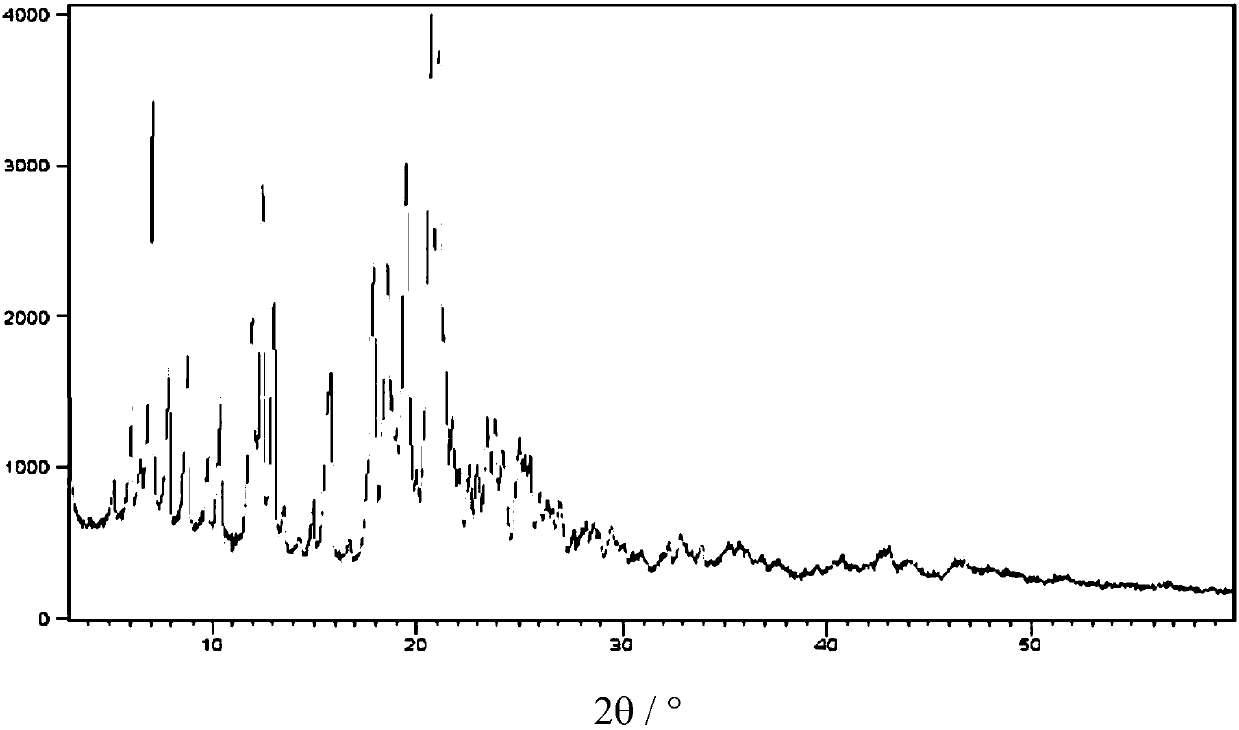

[0050]Under the protection of nitrogen, add 10g of silodosin and 50mL of isopropanol into the three-necked flask, stir, raise the temperature to 50-60°C, and keep it warm for 1 hour. The silodosin is completely dissolved. Slowly drop it into 40mL of n-heptane preheated to 50-60°C, keep stirring the crystallization feed liquid for 2 hours after dropping, then control the cooling rate at 10°C / hour, and cool the feed liquid to 0-10°C , heat preservation and crystallization for 2 hours, filter under the protection of nitrogen, wash the crystals with a small amount of n-heptane, and vacuum-dry the obtained crystals to obtain 8.5 g of silodosin in the β crystal form, with a yield of 85%. The results of the XRD detection spectrum of the sample are attached Figure 4 As shown in table 3, the DSC detection spectrum result of sample is as attached Figure 5 As shown, the crystal melting range is 105.70°C-107.30°C.

[0051] Table 3 Comparison Table of Main 2θ Diffraction Angles in XRD ...

Embodiment 3

[0054] Under the protection of nitrogen, add 10g of silodosin and 60mL of isopropanol into the three-necked flask, stir, raise the temperature to 50-60°C, and keep it warm for 1 hour. The silodosin is completely dissolved. Slowly drop it into 50mL n-heptane preheated to 50-60°C. After dropping, keep the crystallization feed liquid for 2 hours and then control the cooling rate at 15°C / hour to cool the feed liquid to 0-10°C. , heat preservation and crystallization for 2 hours, filtered under nitrogen protection, washed the crystals with a small amount of n-heptane, and vacuum-dried the obtained crystals to obtain 8.1 g of silodosin in the β crystal form, with a yield of 81%. The results of the XRD detection spectrum of the sample are attached Image 6 As shown in table 4, the DSC detection spectrum result of sample is as attached Figure 7 As shown, the melting range of silodosin in the β crystal form obtained in this example is 105.40°C-106.96°C.

[0055] Table 4 Comparison T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com