Sea-land transition phase shale gas pressure fracturing fluid, preparation method and applications thereof

A shale and gas pressure technology, which is applied in the fields of fracturing fluid for shale gas fracturing, shale gas tight gas reservoir stimulation, VCR radical fracturing fluid for shale gas fracturing in sea-land transitional facies and its preparation, It can solve the problems of incomplete gel breaking, large reservoir damage, long swelling time, etc., and achieve the effect of strong sand-carrying performance, wide temperature range and complete gel breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

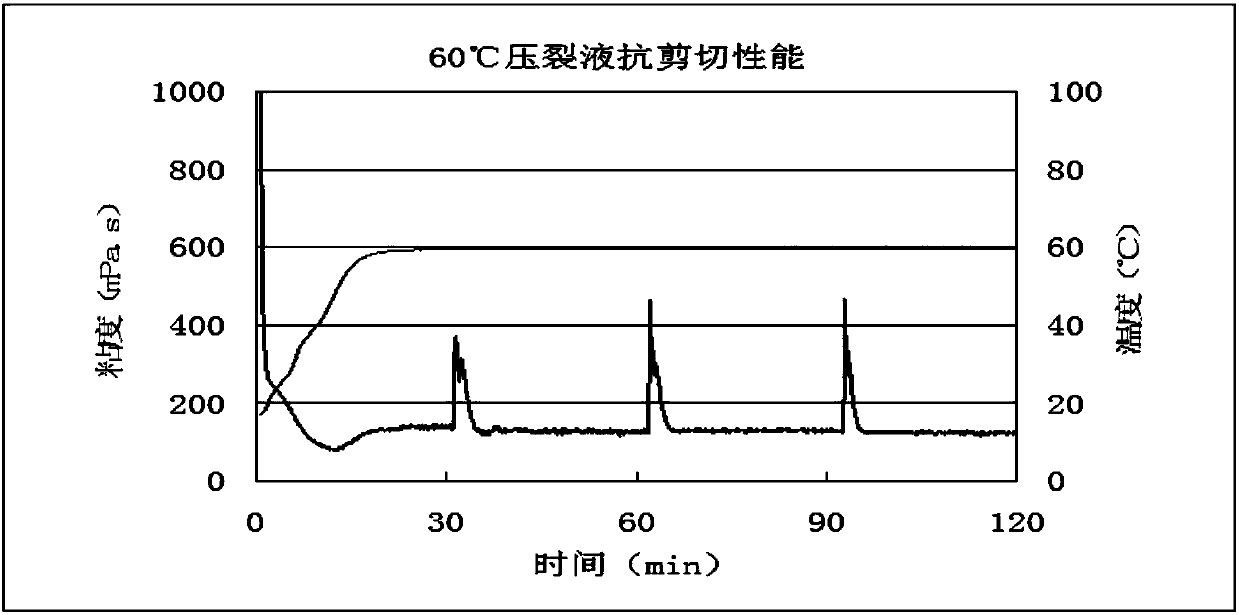

[0036] This example provides a preferred shale gas fracturing fluid with transitional marine-terrestrial facies, denoted as 1# fracturing fluid, in terms of mass percentage, its formula consists of: 0.3% thickener, 0.3% anti-swelling agent, auxiliary 0.3% row synergist, 0.3% water lock treatment agent, 0.3% foaming agent, 0.5% potassium chloride, 0.1% organic boron zirconium crosslinking agent, 0.01% gel breaker, and 97.89% water.

[0037] In this embodiment, the thickener is VCR radical polyacrylamide with a molecular weight of 200. The drainage aid synergist is SR18Y fluorocarbon surfactant. The water-locking treatment agent can be composed of fluorocarbon surfactant, gemini quaternary ammonium salt, and water. Described foaming agent selects sodium lauryl sulfate for use. The breaker is ammonium persulfate.

[0038] This system is suitable for the formation temperature within 80°C.

[0039] The preparation method of the shale gas fracturing fluid in transitional marine-...

Embodiment 2

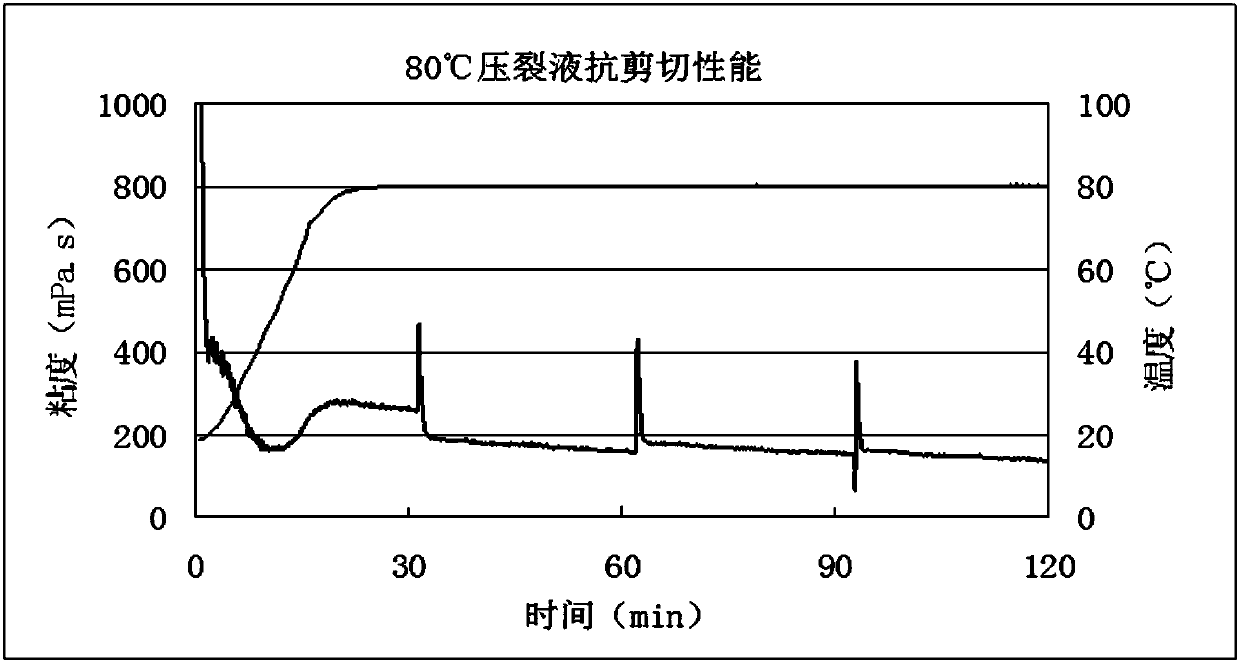

[0055] This example provides a preferred shale gas fracturing fluid with transitional marine-terrestrial facies, which is denoted as 2# fracturing fluid. In terms of mass percentage, its formula consists of: 0.5% thickener, 0.4% anti-swelling agent, 0.35% row synergist, 0.4% water lock treatment agent, 0.4% foaming agent, 0.5% potassium chloride, 0.5% organic boron zirconium crosslinking agent, 0.05% gel breaker, and 96.9% water.

[0056] In this embodiment, the thickener is VCR radical polyacrylamide with a molecular weight of 3 million. The drainage aid synergist is SR18Y fluorocarbon surfactant. Described water locking treatment agent is with embodiment 1. Described foaming agent selects sodium lauryl sulfate for use. The gel breaker is potassium persulfate.

[0057] The system is suitable for fracturing systems with temperatures within 120°C.

[0058] The preparation method of 2# fracturing fluid may further comprise the steps:

[0059] 1) Preparation of base liquid ...

Embodiment 3

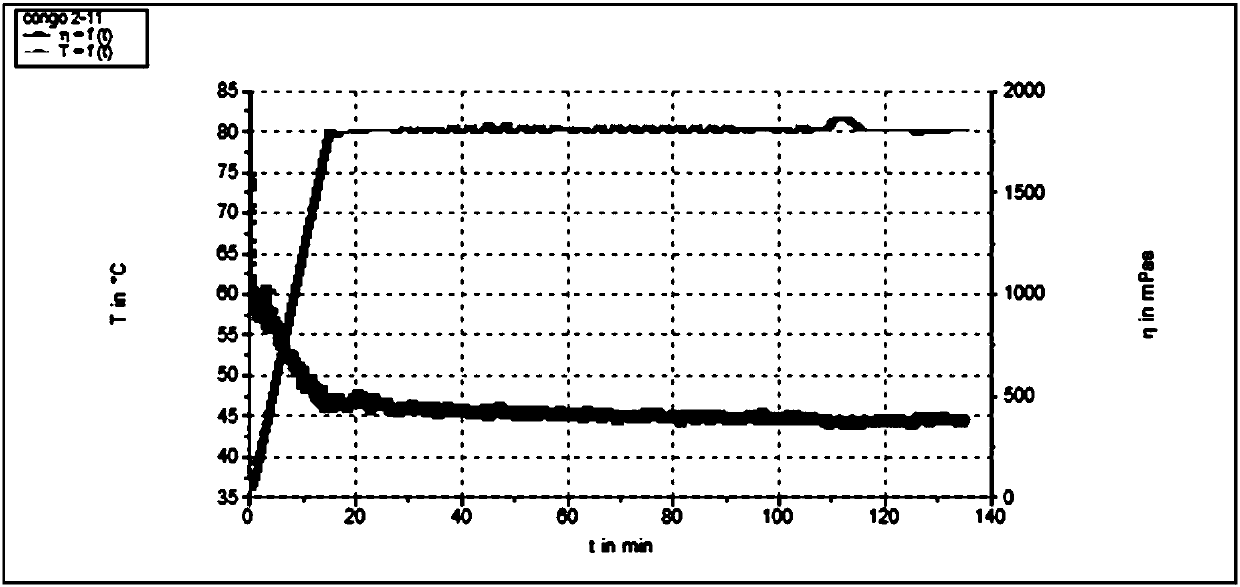

[0073] This example provides a preferred shale gas fracturing fluid with transitional marine-terrestrial facies, which is denoted as 3# fracturing fluid. In terms of mass percentage, its formula consists of: 0.6% thickener, 0.5% anti-swelling agent, 0.4% row synergist, 0.5% water lock treatment agent, 0.5% foaming agent, 0.5% potassium chloride, 1% organic boron zirconium crosslinking agent, 0.1% gel breaker, and 95.9% water.

[0074] In this embodiment, the thickener is VCR radical polyacrylamide with a molecular weight of 5 million. The drainage aid synergist is TF-1 fluorocarbon surfactant. Described water locking treatment agent is with embodiment 1. Described foaming agent selects sodium lauryl sulfate for use. The gel breaker is potassium persulfate.

[0075] The preparation method of 3# fracturing fluid may further comprise the steps:

[0076] 1) Preparation of base liquid

[0077] Under stirring conditions, add 0.6kg thickener to 95.9kg water, after the thickener ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com