Preparation method of composite hydride hydrogen storage material and composite hydride hydrogen storage material

A hydrogen storage material and hydride technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as kinetic obstacles, and achieve the effect of simple process and strong safety and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: prepare Li-Mg-N-H (xMg (NH 2 ) 2 -yLiH) system

[0042] (1) Take a certain amount of magnesium amide and a corresponding amount of lithium hydride (such as 2Mg(NH 2 ) 2 -3LiH system, the molar ratio of Mg and Li is 2:3), and then added to the ball mill jar, followed by injection of argon.

[0043] (2) After adding magnesium amide, lithium hydride and argon as described in step (1), place the ball mill jar on a planetary ball mill at 50-200 rpm to mix evenly, and the ball milling time is 24h-36h.

[0044] (3) The sample obtained after mixing uniformly as in step (2) was subjected to a temperature programmed deammonization test (TPD-MS) to determine its dehydrogenation temperature, and an appropriate temperature was selected for dehydrogenation.

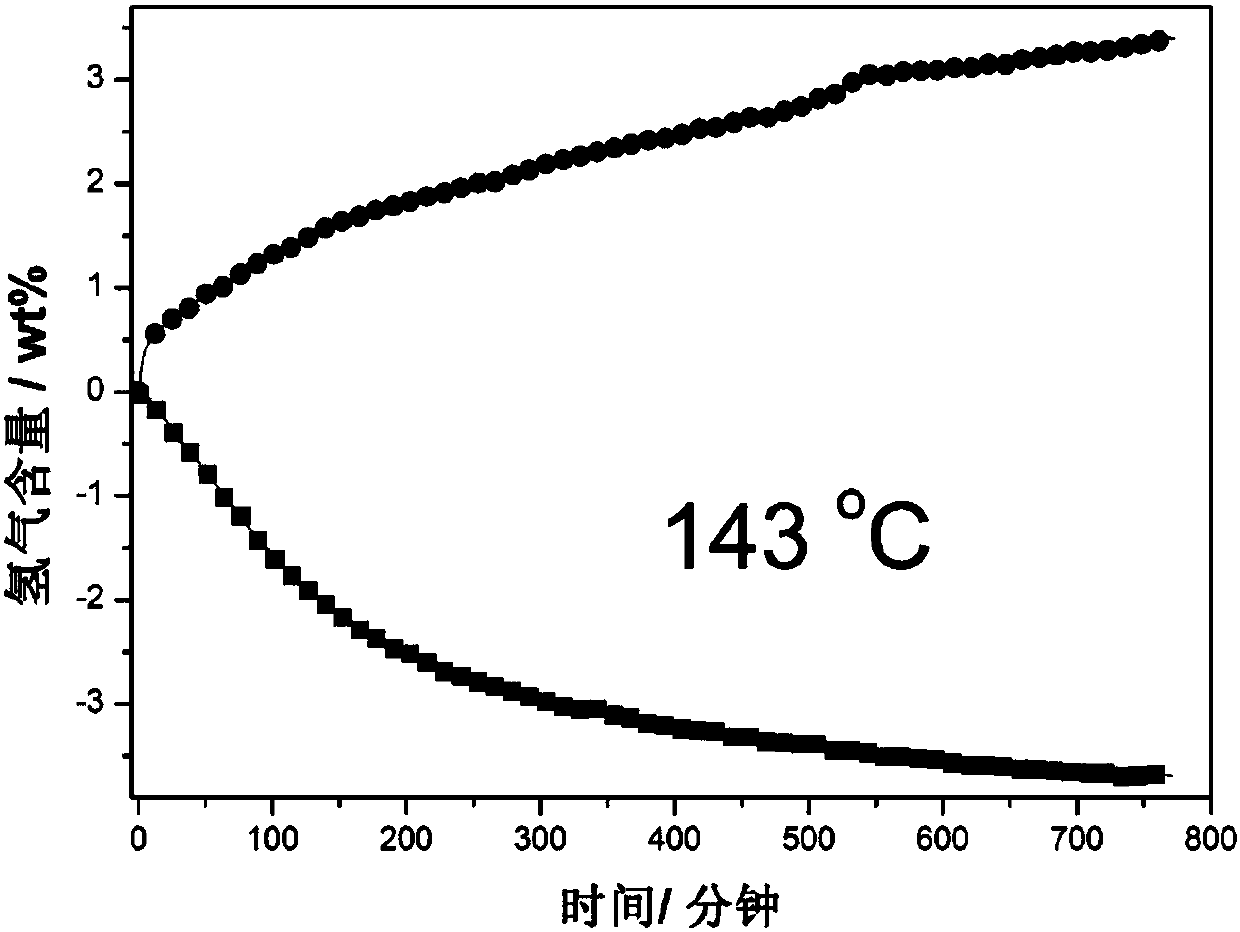

[0045] (4) Take out the sample mixed in step (2) and place it in a pressure-resistant reactor for dehydrogenation reaction, and the dehydrogenation temperature is between 20 and 150°C;

[0046] (5) As in step ...

Embodiment 2

[0048] Embodiment 2: Preparation of LiBH 4 Modified Li-Mg-N-H(xMg(NH 2 ) 2 -yLiH-zLiBH 4 )system

[0049] (1) Take a certain amount of magnesium amide and a corresponding amount of lithium hydride and lithium borohydride (such as 2Mg(NH 2 ) 2 -3LiH-4LiBH 4 The system is Mg(NH 2 ) 2 , LiH and LiBH 4 The molar ratio is 2:3:4), and then added to the ball mill jar, followed by injection of argon.

[0050] (2) After adding magnesium amide and the corresponding amount of lithium hydride and lithium borohydride as described in step (1), place the ball mill jar on a planetary ball mill at 50-200rpm and mix evenly, so that the three main materials and additives can be fully mixed well mixed.

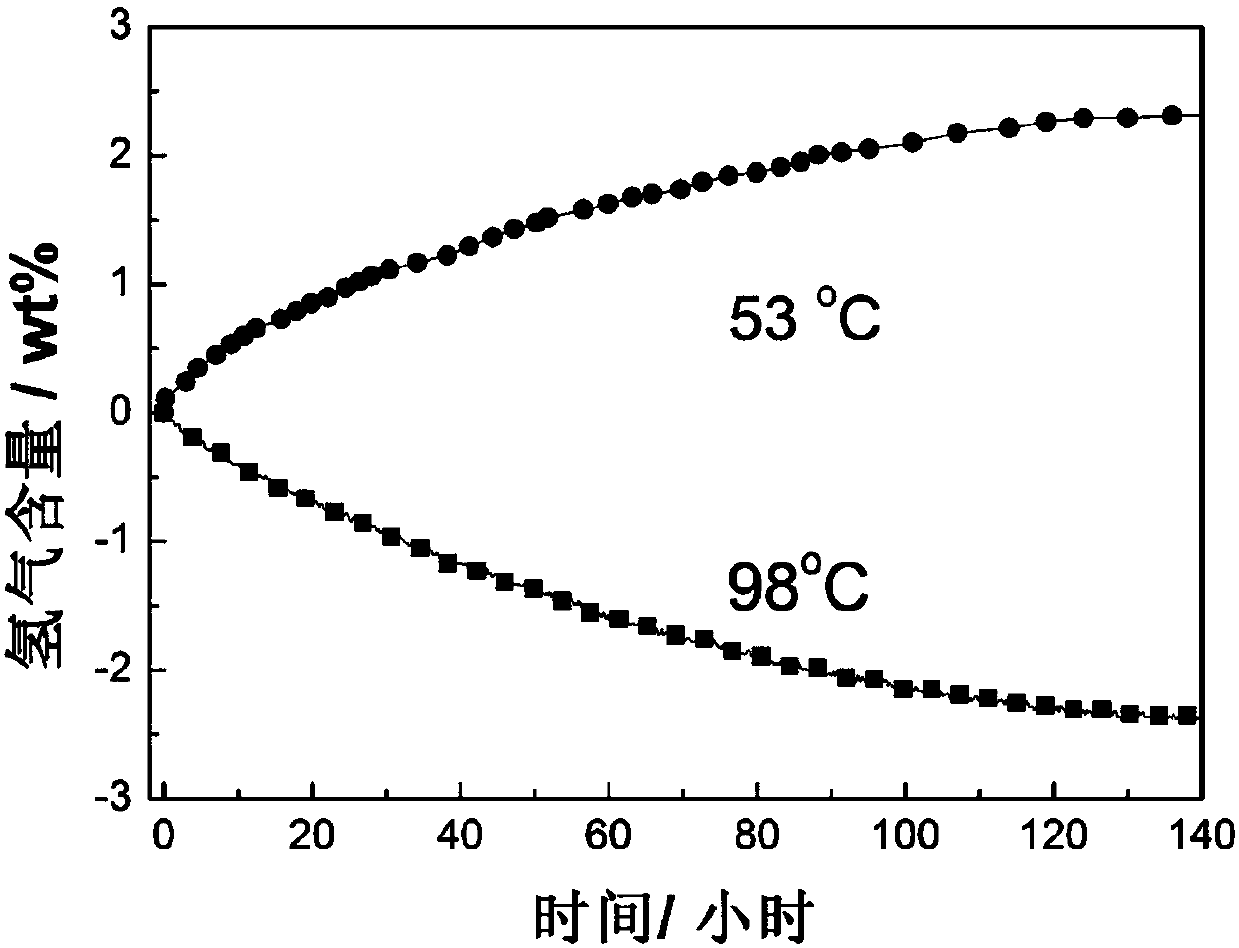

[0051] (3) The sample obtained after mixing uniformly as in step (2) was subjected to a temperature programmed deammonization test (TPD-MS) to determine its dehydrogenation temperature, and an appropriate temperature was selected for dehydrogenation.

[0052] (4) Take out the sample mi...

Embodiment 3

[0055] Embodiment 3: prepare KH modified Li-Mg-N-H(xMg(NH 2 ) 2 -yLiH-zKH) system

[0056] (1) Take a certain amount of magnesium amide and corresponding amount of lithium hydride and potassium hydride (such as Mg(NH 2 ) 2 -1.9LiH-0.1KH system, Mg(NH 2 ) 2 , LiH and KH in a molar ratio of 1:1.9:0.1), and then added to the ball mill jar, followed by injection of argon.

[0057] (2) After adding magnesium amide and the corresponding amount of lithium hydride and potassium hydride as described in step (1), place the ball mill jar on a planetary ball mill at 50-200rpm and mix evenly, so that the three main materials and additives can be fully mixed uniform.

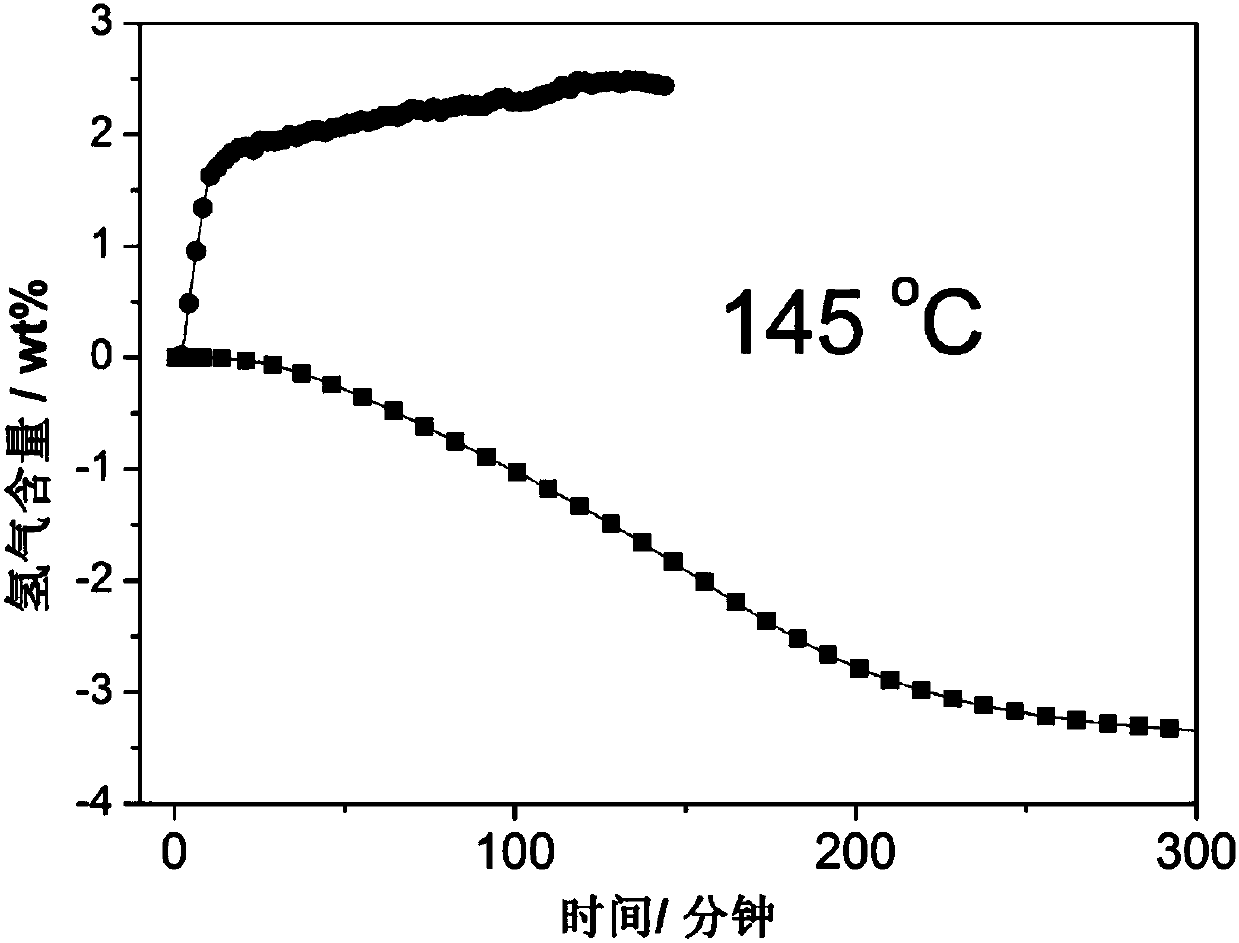

[0058] (3) The sample obtained after mixing uniformly as in step (2) was subjected to a temperature programmed deammonization test (TPD-MS) to determine its dehydrogenation temperature, and an appropriate temperature was selected for dehydrogenation.

[0059] (4) Take out the sample mixed in step (2) and place it in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com