A high-efficiency catalytic sodium hypochlorite reclaimed water treatment process based on a composite catalytic bed

A technology for catalyzing sodium hypochlorite and composite catalytic bed, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Achieve the effect of improving applicability, improving catalytic activity and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

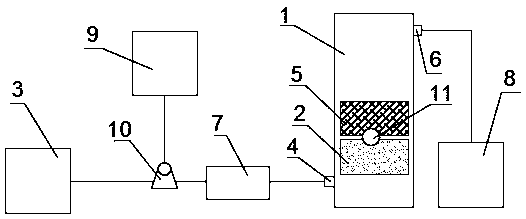

[0028] Example 1 A high-efficiency catalytic sodium hypochlorite water treatment system based on a composite catalytic bed

[0029] Such as figure 1 As shown, the present invention provides a kind of high-efficiency catalytic sodium hypochlorite reclaimed water treatment system based on composite catalytic bed, comprising oxidation tower 1, activated carbon catalyst bed 2, reclaimed water storage tank 3, reclaimed water inlet 4, molecular sieve catalyst bed 5, Reclaimed water outlet 6, liquid mixer 7, outlet water storage tank 8, sodium hypochlorite storage tank 9, lift pump 10, oxidation tower sealing port 11.

[0030] Described reclaimed water storage tank 3 is used for storing reclaimed water, and described sodium hypochlorite storage tank 9 is used for storing sodium hypochlorite solution, and described reclaimed water storage tank 3 is communicated with liquid mixer 7 by lift pump 10, and described sodium hypochlorite storage tank 9 is lifted Pump 10 communicates with li...

Embodiment 2

[0036] Embodiment 2 A kind of high-efficiency catalytic sodium hypochlorite water treatment process based on composite catalytic bed, comprises the following steps:

[0037] (1) Catalyst preparation: Put the powders of nickel nitrate, iron nitrate and magnesium nitrate into a ball mill to grind and mix them evenly, then prepare the mixed powder into two parts of 5% aqueous solution, put molecular sieve and activated carbon into it respectively, soak for 12 hours, Drying, then calcining in a muffle furnace, and cooling to obtain activated carbon catalysts and molecular sieve catalysts;

[0038] Wherein, the mass ratio of nickel nitrate, ferric nitrate, magnesium nitrate is 5:2:1;

[0039] MCM41 type molecular sieves are used for molecular screening, and the specific surface area of specific molecular sieves exceeds 1000m 2 / g, the relative crystallinity exceeds 90%, the loss on ignition does not exceed 5%, and the pore size is distributed within the range of 2-5nm.

[0040]...

Embodiment 3

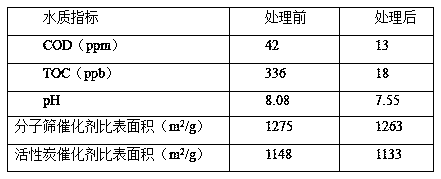

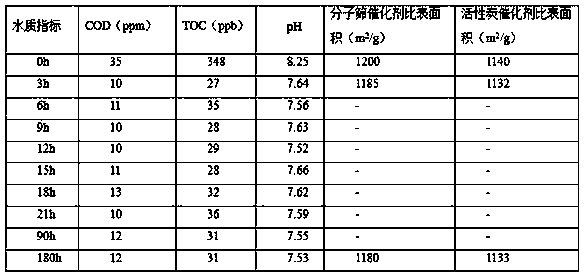

[0059] Example 3 A kind of application of water treatment in high-efficiency catalytic sodium hypochlorite based on composite catalytic bed

[0060] The present invention is described in detail below according to the facts, and the implementation effect of the present invention is as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com