Air floating type semi-shortcut nitrification-anaerobic ammonia oxidation reactor

A technology of semi-short-range nitrification and anammox, which is applied in the field of air-flotation semi-short-range nitrification-anammox reactor, which can solve the problems of unfavorable large-scale popularization and application, complicated reactor structure, and reduced floor space. , to achieve the effect of low construction cost, small footprint and simple reactor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited thereto:

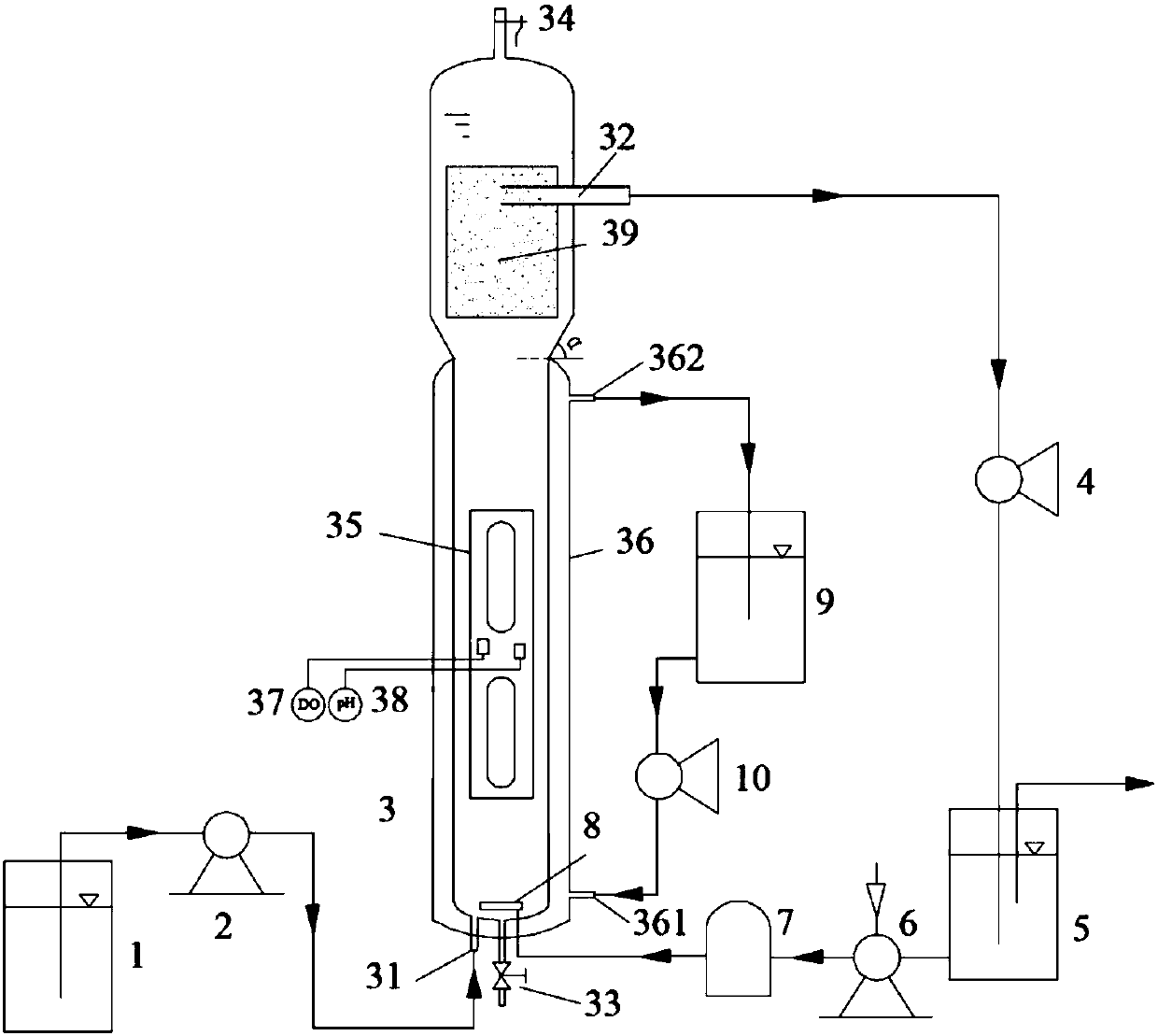

[0019] Such as figure 1 As shown, the device mainly includes water inlet tank 1, water inlet pump 2, reactor body 3, water outlet pump 4, water outlet tank 5, dissolved air pump 6, pressure stabilizing tank 7, water distribution device 8, constant temperature tank 9 and circulation pump 10 , wherein, the bottom of the reactor body 3 is provided with a water inlet 31 and a mud outlet 33, the top is provided with a water outlet 32 and an exhaust port 34, and a water distribution device 8, a DO probe 37, a pH probe 38 and a dynamic The membrane module 39 is provided with an observation window 35 and a constant temperature water bath layer 36 on the outside, the water distribution device 8 is at the bottom of the reactor body 3, and the constant temperature water bath layer 36 is provided with a constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com