Biological dealkalizing method for red mud

A technology of dealkalization and red mud, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as low dealkalization efficiency, and achieve easy maintenance, short dealkalization process, and simple mechanical equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

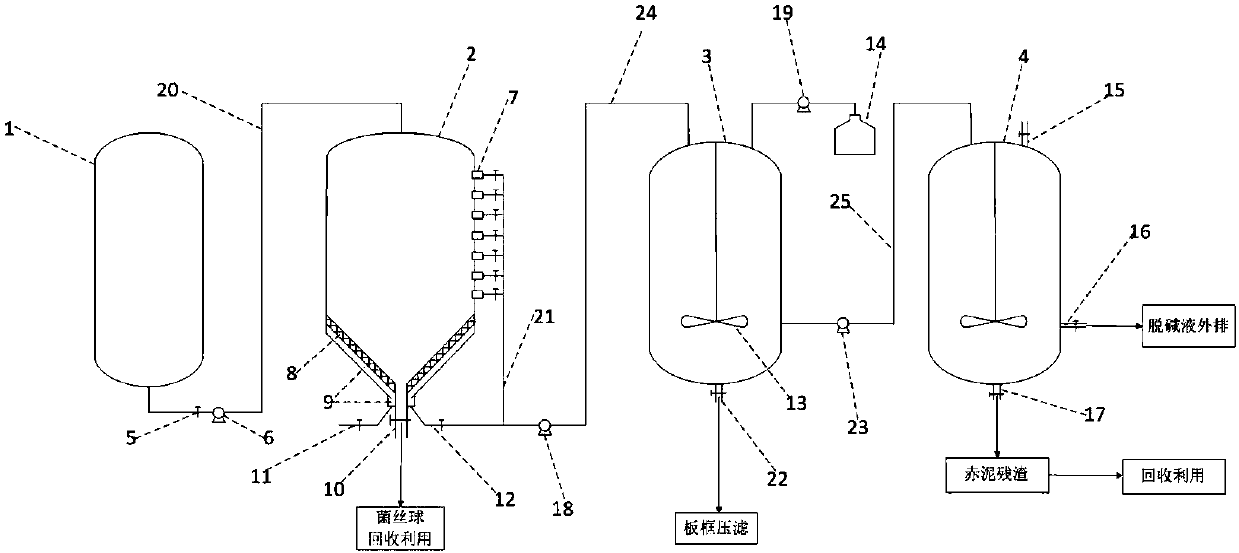

Method used

Image

Examples

Embodiment

[0066] Activate the preserved Aspergillus niger on the PDA plate, elute the mature spores with sterilized physiological saline solution to make a spore suspension, and adjust the concentration of Aspergillus niger spores in the spore suspension to about 1×108 / mL .

[0067] The culture medium is prepared, and its composition ratio is: 10% of sucrose, 0.015% of yeast extract, 0.02% of beef extract, 0.03% of KNO3, and the solvent is deionized water. The medium is added to the fermenter for sterilization. The model of the fermenter is Yangge YGF300 / s, with an effective volume of 20L. Adjust the sterilization parameters of the fermenter to 121.5°C and 103kPa, the sterilization time to 30min, and start the fermenter.

[0068] After the sterilization is completed, wait for the tank to cool down, and inoculate 50 mL of Aspergillus niger spore suspension in the fermenter. The fermentation conditions of the fermenter were set as follows: temperature 33° C., dissolved oxygen 2.6 mg / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com