Eight-speed double-clutch automatic transmission

An automatic transmission and dual-clutch technology, which is applied in the field of vehicle transmission system, can solve the problems of short axial length, reduce the reliability of transmission, increase the difficulty of gear design, etc., and achieve the goal of shortening the radial length, shortening the axial length and simplifying the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

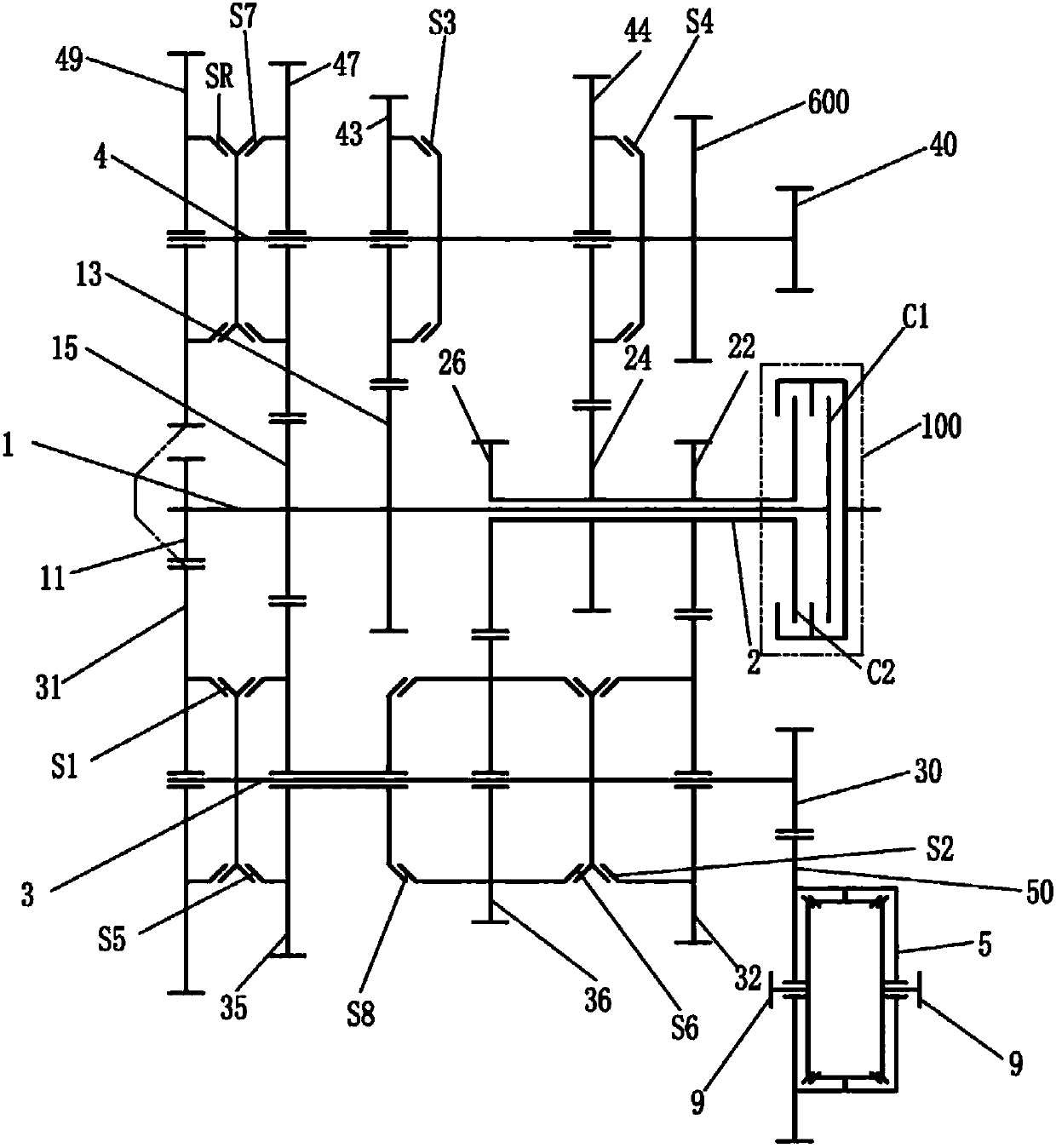

Embodiment 1

[0027] Such as figure 1 As shown, the eight-speed dual-clutch automatic transmission used in automobiles includes two first automatic clutches C1 and second automatic clutches C2 on the same axis, a first input shaft 1, a second input shaft 2, and a first output shaft 3. , The second output shaft 4, the first main reduction driving gear 30, the second main reduction driving gear 40, the main reduction gear 50, and the differential 5. The crankshaft of the engine is connected to the housing of the dual clutch through a flexible disc. The two input shafts 1, 2 and the two output shafts 3, 4 are arranged parallel to each other. The dual clutch 100 includes a first automatic clutch C1 and a second automatic clutch C2. The first automatic clutch C1 includes a first driving disc and a first driven disc. The first driving disc and the housing of the dual clutch are connected by spline sliding. It also transmits torque. The first driven disc and the first input shaft 1 are splined to ...

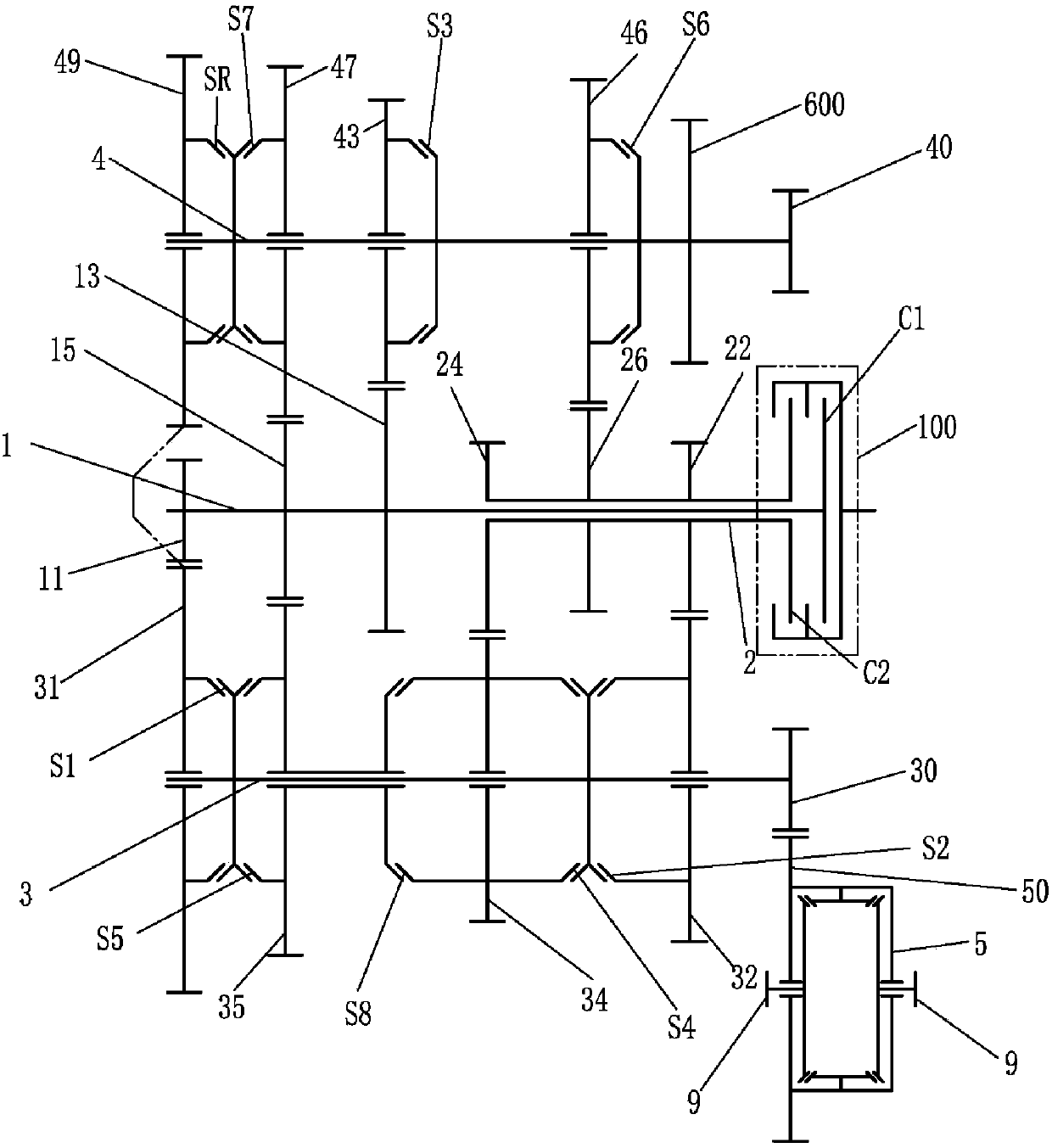

Embodiment 2

[0053] Such as figure 2 As shown, compared with Embodiment 1, the eight-speed dual-clutch automatic transmission shown in Embodiment 2 differs in that: the second input shaft 2 is sequentially fixed with a fourth-speed driving gear 24 and a sixth-speed driving gear from the end away from the dual clutch. Gear 26, second-speed driving gear 22, fourth-speed driven gear 34 are correspondingly sleeved on the first output shaft 3, and sixth-speed driven gear 46 is correspondingly sleeved on the second output shaft 4; correspondingly, the fourth-speed synchronizer S4 is set On the first output shaft 3, the sixth-speed synchronizer S6 is provided on the second output shaft 4, and the eighth-speed synchronizer S8 is fixed on the fifth-speed driven gear 35 and can be engaged with and separated from the fourth-speed driven gear 34; It can ensure that the eighth gear ratio is smaller than the seventh gear ratio to meet actual requirements.

[0054] In other embodiments, it can also be arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com