Cladding supermode interference based fiber reflective probe sensor and manufacturing method thereof

A reflective, sensor technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of being easily interfered by other external factors, very high manufacturing process requirements, and high processing technology requirements. Easy field detection, compact, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

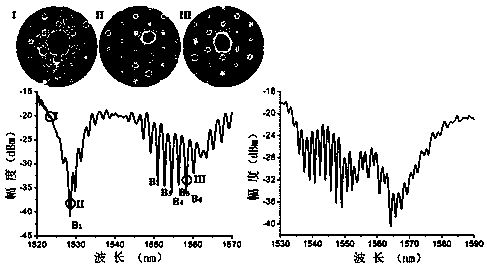

[0033] refer to figure 1 , figure 2 and image 3 , a method for manufacturing an optical fiber reflective probe sensor based on cladding supermode interference, comprising the following steps:

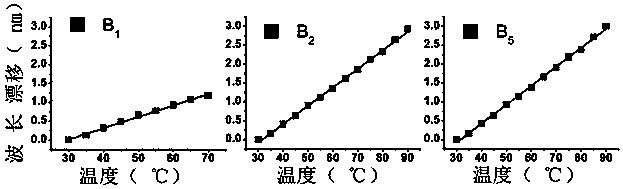

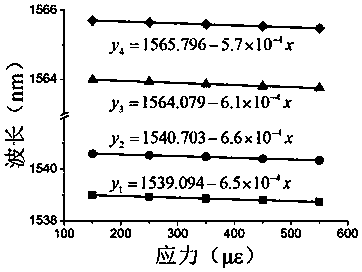

[0034] 1. Connect the two ends of the all-solid photonic bandgap fiber to the broadband light source and the spectrometer respectively through the single-mode fiber. The all-solid photonic bandgap fiber and the single-mode fiber are welded to the core to avoid interference effects. The wavelength range of the broadband light source needs to cover the wavelength range to be processed The wavelength variation range of the interferometer. Preferably, the single-mode fiber used in step (1) has a core diameter of 8.3 μm and a diameter of 125 μm, and the length of the all-solid photonic bandgap fiber used is greater than 10 mm. In the embodiment of the present invention, the all-solid photonic bandgap fiber used supports the core LP at the same time 01 mode with a high index column in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com