Method for processing frost snow preserved meat

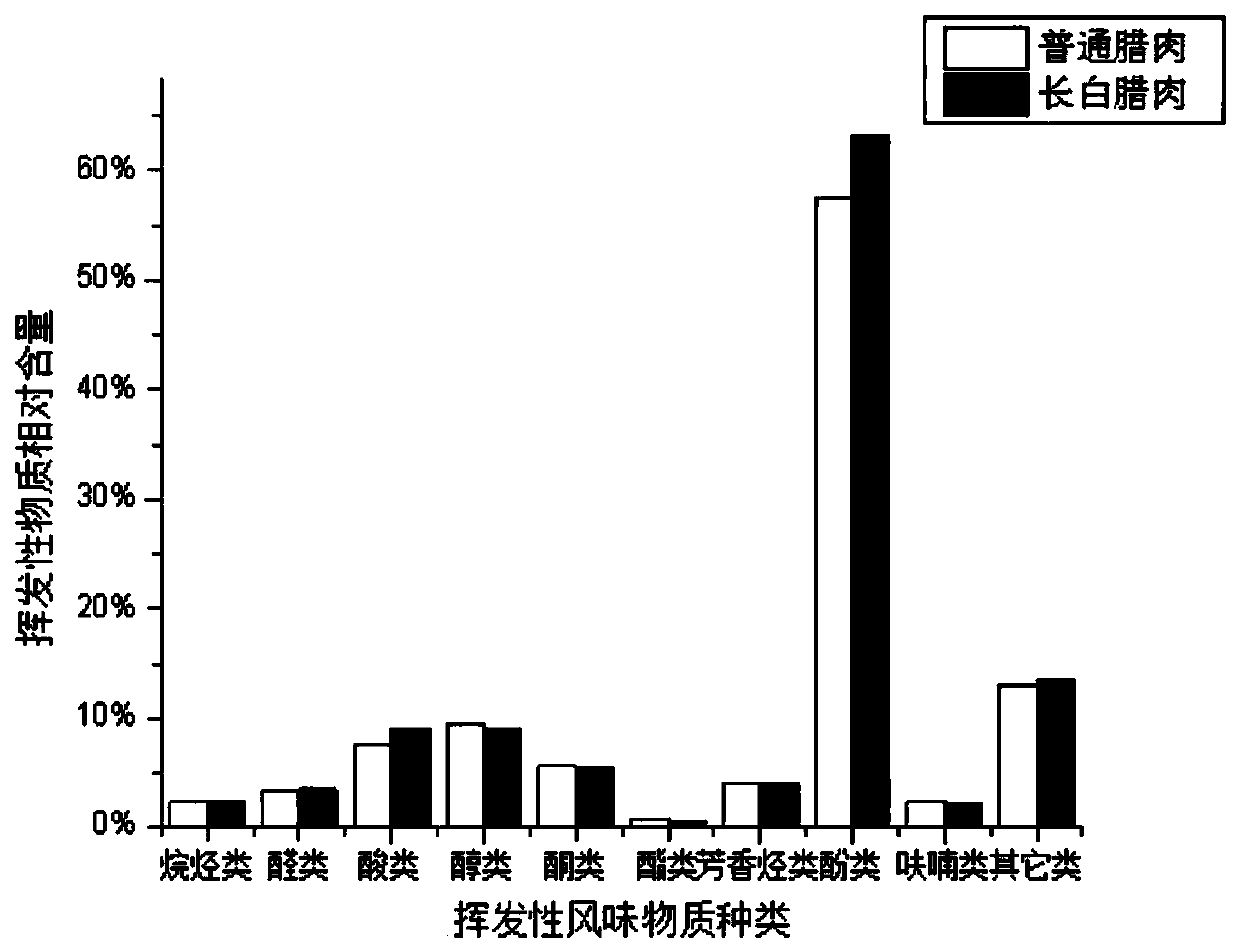

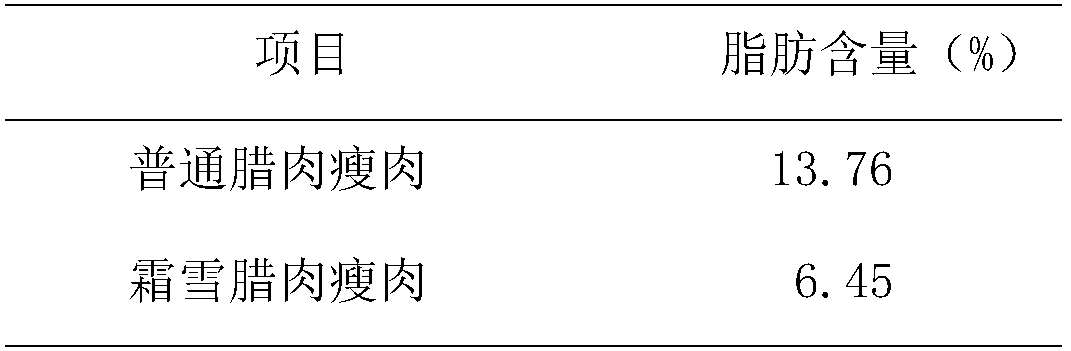

A processing method and bacon technology, applied in food science and other directions, can solve the problems of single external form, high fat content, low degree of differentiation, etc., to achieve the effect of satisfying healthy diet and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

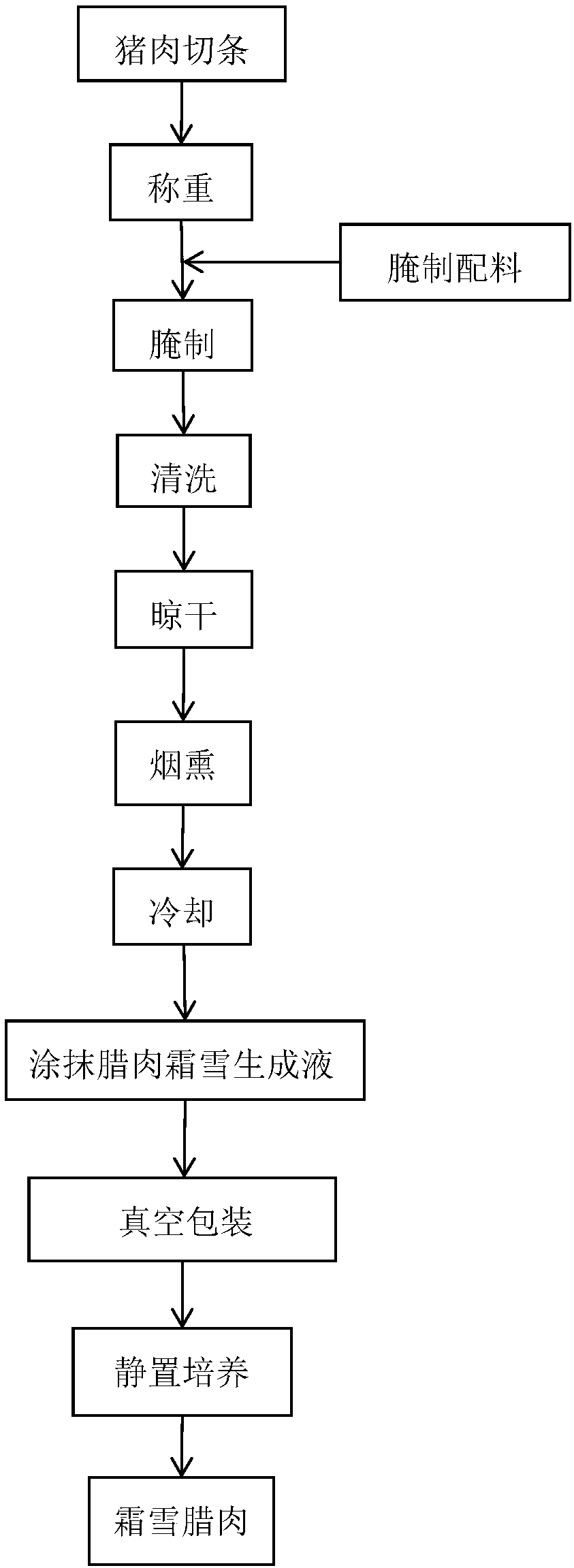

[0052] A processing method for frosted snow bacon, mainly comprising the following steps:

[0053] Step 1. Preparation of raw materials: Weigh fresh pork hind legs, and cut it into 20cm long, 6cm wide, and 1.0cm thick meat pieces with uniform fat and leanness.

[0054] Step 2. Material preparation: salt 3, white sugar 0.5, cooking wine 1.5, monosodium glutamate 0.2, dried chili 0.5, pepper 0.1, cinnamon 0.2, star anise 0.05, clove 0.2, pepper 0.4, anise 0.8, bay leaf 0.2 and kaempferen 0.05.

[0055] Step 3. Preparation of frost and snow generating solution: the concentration is 0.5×10 5 cfu / mL of Staphylococcus xylosus at a concentration of 0.8×10 5 cfu / mL plant lactic acid bacteria, 10W / g protease 0.01, 10W / g lipase 0.01, arginine 0.01, leucine 0.01, glutamic acid 0.01, tyrosine 0.01, alanine 0.01, glucose 1.0, salt 0.5 and water 100.

[0056] Step 4, adding the marinating material in step 2 after weighing the pork in step 1.

[0057] Step 5, marinating the pork that was...

Embodiment 2

[0066] A processing method for frosted snow bacon, mainly comprising the following steps:

[0067] Step 1. Preparation of raw materials: Weigh fresh pork hind legs, and cut it into 25cm long, 10cm wide, and 2.0cm thick meat pieces with uniform fat and leanness.

[0068] Step 2. Material preparation: salt 8, white sugar 3, cooking wine 3, monosodium glutamate 0.5, dried chili 2, pepper 0.15, cinnamon 1, star anise 0.08, clove 0.4, pepper 1, anise 1.2, bay leaf 0.4 and kaempferen 0.1.

[0069] Step 3. Preparation of frost and snow generating solution: the concentration is 8×10 6 cfu / mL of Staphylococcus xylosus at a concentration of 2 × 10 6 cfu / mL plant lactic acid bacteria, 10W / g protease 0.05, 10W / g lipase 0.05, arginine 0.05, leucine 0.05, glutamic acid 0.05, tyrosine 0.02, alanine 0.05, glucose 2.0, salt 0.9 and water 100.

[0070] Step 4, adding the marinating material in step 2 after weighing the pork in step 1.

[0071] Step 5, marinating the pork that was added into...

Embodiment 3

[0080] A processing method for frosted snow bacon, mainly comprising the following steps:

[0081] Step 1. Raw material preparation: Weigh fresh pork hind legs, and cut it into 22cm long, 8cm wide, and 1.5cm thick meat pieces with uniform fat and leanness.

[0082] Step 2. Material preparation: salt 5, white sugar 1.5, cooking wine 2.2, monosodium glutamate 0.3, dried chili 1.2, pepper 0.12, cinnamon 0.6, star anise 0.06, clove 0.3, pepper 0.7, anise 1, bay leaves 0.3 and kaempferen 0.08.

[0083] Step 3. Preparation of frost and snow generating solution: the concentration is 4×10 6 cfu / mL of Staphylococcus xylosus at a concentration of 1 × 10 5 cfu / mL plant lactic acid bacteria, 10W / g protease 0.1, 10W / g lipase 0.1, arginine 0.1, leucine 0.1, glutamic acid 0.1, tyrosine 0.05, alanine 0.1, glucose 1.5, salt 0.7 and water 100.

[0084] Step 4, adding the marinating material in step 2 after weighing the pork in step 1.

[0085] Step 5: marinate the pork that was added in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com