Filter tower packing for processing VOCs gas and odorous gases

A malodorous gas and filter tower technology, applied in the field of environmental governance, can solve the problems of inability to provide nutrients for microorganisms, inability to adapt to different gas sources, and high pressure drop of natural packing, and achieve the goal of many internal effective units, wide application range, and high organic load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

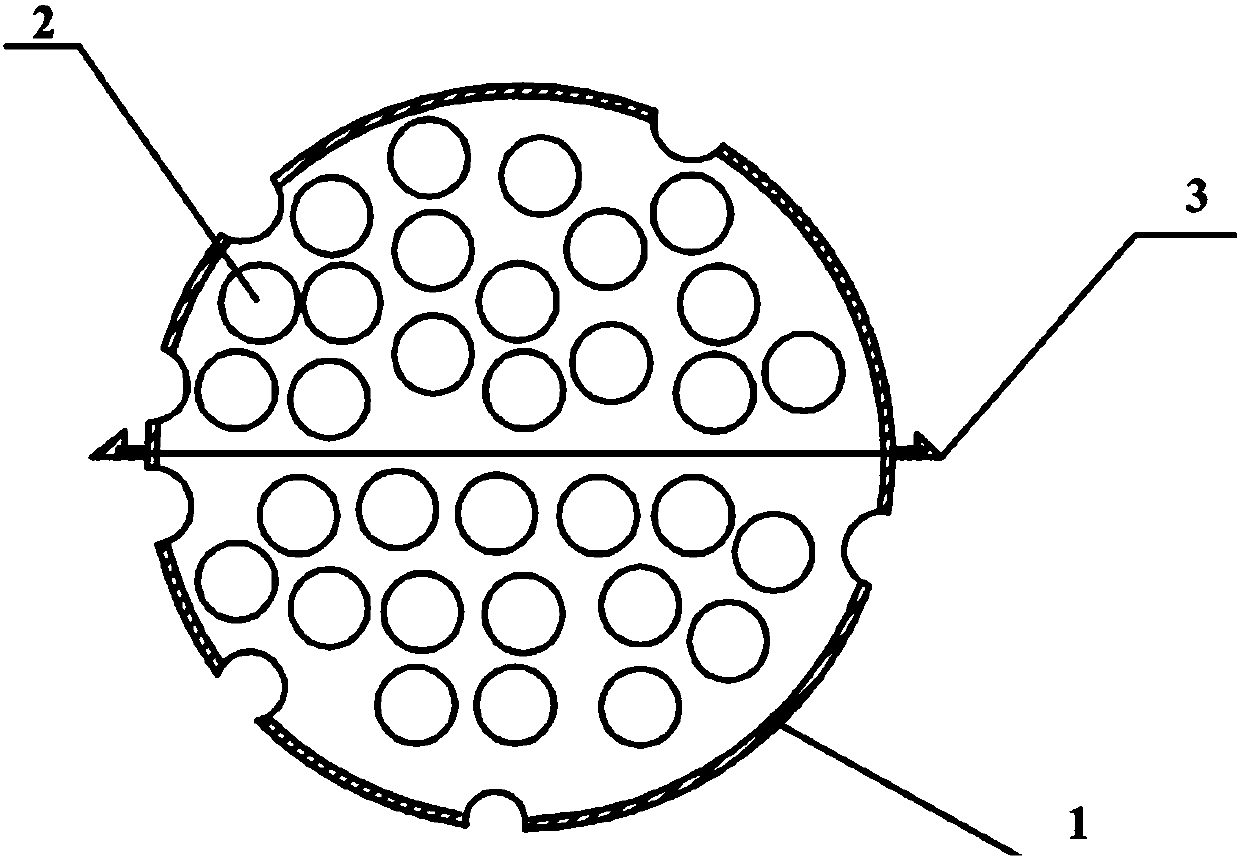

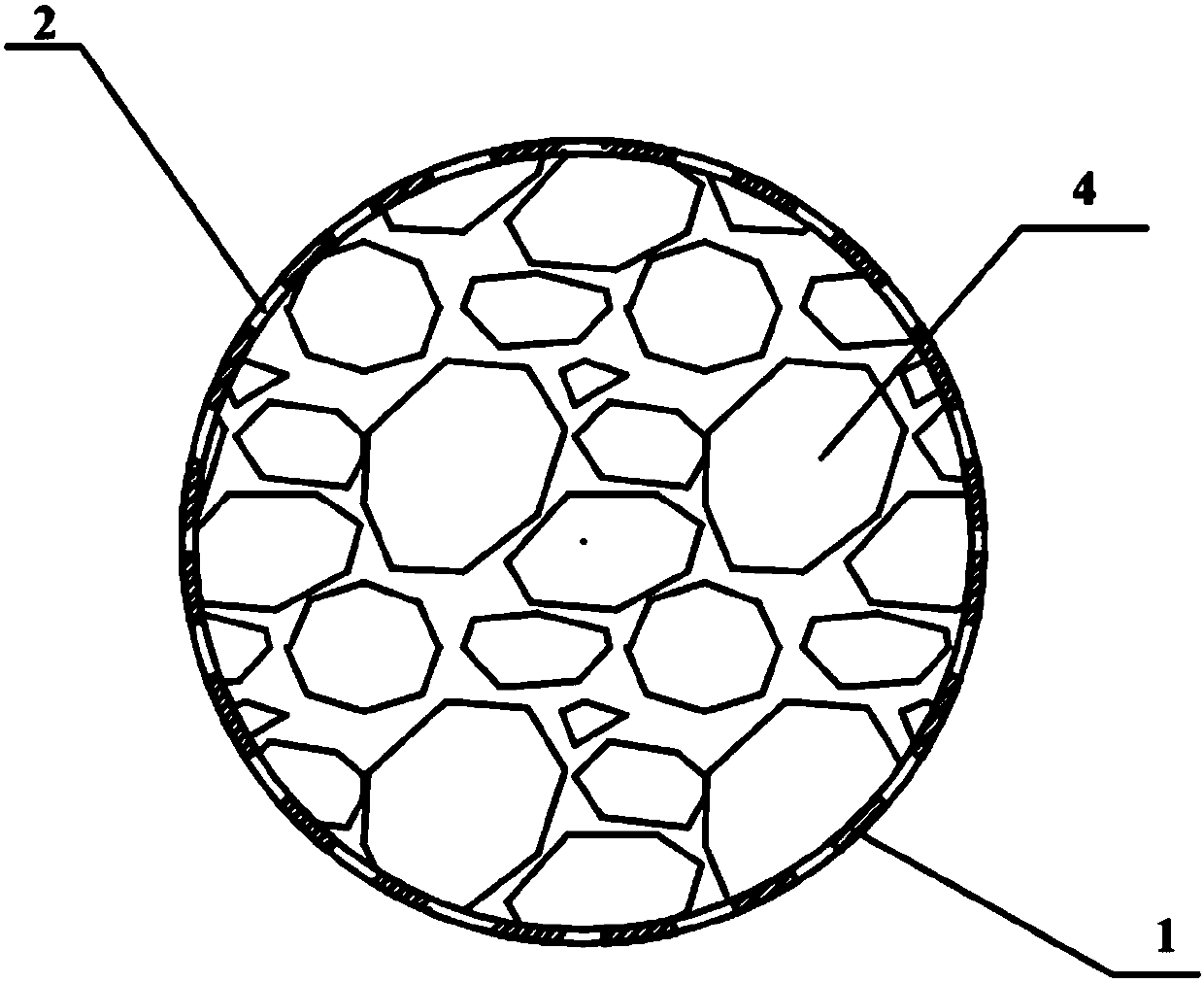

[0022] Such as figure 1 As shown, the filter tower packing is made of porous spherical shell 1 and internal packing 4, and by volume, the internal packing 4 is made up of 40% pine bark, 20% bamboo charcoal, 10% shellfish, and 30% polyurethane foam. The diameter of the porous spherical shell 1 is 44 mm, and the wall thickness is 1 mm. The circular holes 2 with a diameter of 5 mm are evenly distributed on the porous spherical shell 1 , and the number of the circular holes 2 is 309. The porous spherical shell 1 is made of high-density polyethylene. The porous spherical shell 1 is composed of two hemispherical shells, and the two hemispherical shells are connected by a spherical shell opening and closing part 3 . The particle size of pine bark, bamboo charcoal, shellfish and polyurethane foam is 6mm. The inner filler 4 is loaded with functional bacteria by spray drying and curing.

Embodiment 2

[0024] The filter tower packing is composed of a porous spherical shell 1 and an internal packing 4, and the internal packing 4 is composed of 50% pine bark, 30% bamboo charcoal, 5% shellfish and 15% polyurethane foam by volume. The porous spherical shell 1 has a diameter of 35 mm and a wall thickness of 1 mm. The circular holes 2 with a diameter of 3 mm are evenly distributed on the porous spherical shell 1 , and the number of the circular holes 2 is 400. The porous spherical shell 1 is made of high-density polyethylene. The particle size of pine bark, bamboo charcoal, shellfish and polyurethane foam is 20mm. The inner filler 4 is loaded with functional bacteria by spray drying and curing.

[0025] Application example: Treatment of VOCs and malodorous gases in petrochemical and domestic sewage mixing tanks in Liaohua sewage treatment plant

[0026] A biofiltration tower with a height of 3m and a diameter of 1.4m is used, and the filling is 1.5m 3 Filter tower filler of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com