Fiber composite material and method for producing same by virtue of RTM forming method

A fiber composite material and a molding method technology, which are applied in the field of fiber composite materials and the production of the composite material by using the RTM molding method, can solve the problem that the batch setting processing requirements cannot meet the production process requirements of hot-melt prepregs, and the viscosity is low and cannot be formed into a film. and other problems, to achieve the effect of large-scale stereotype processing, meeting the requirements of the injection process, and good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

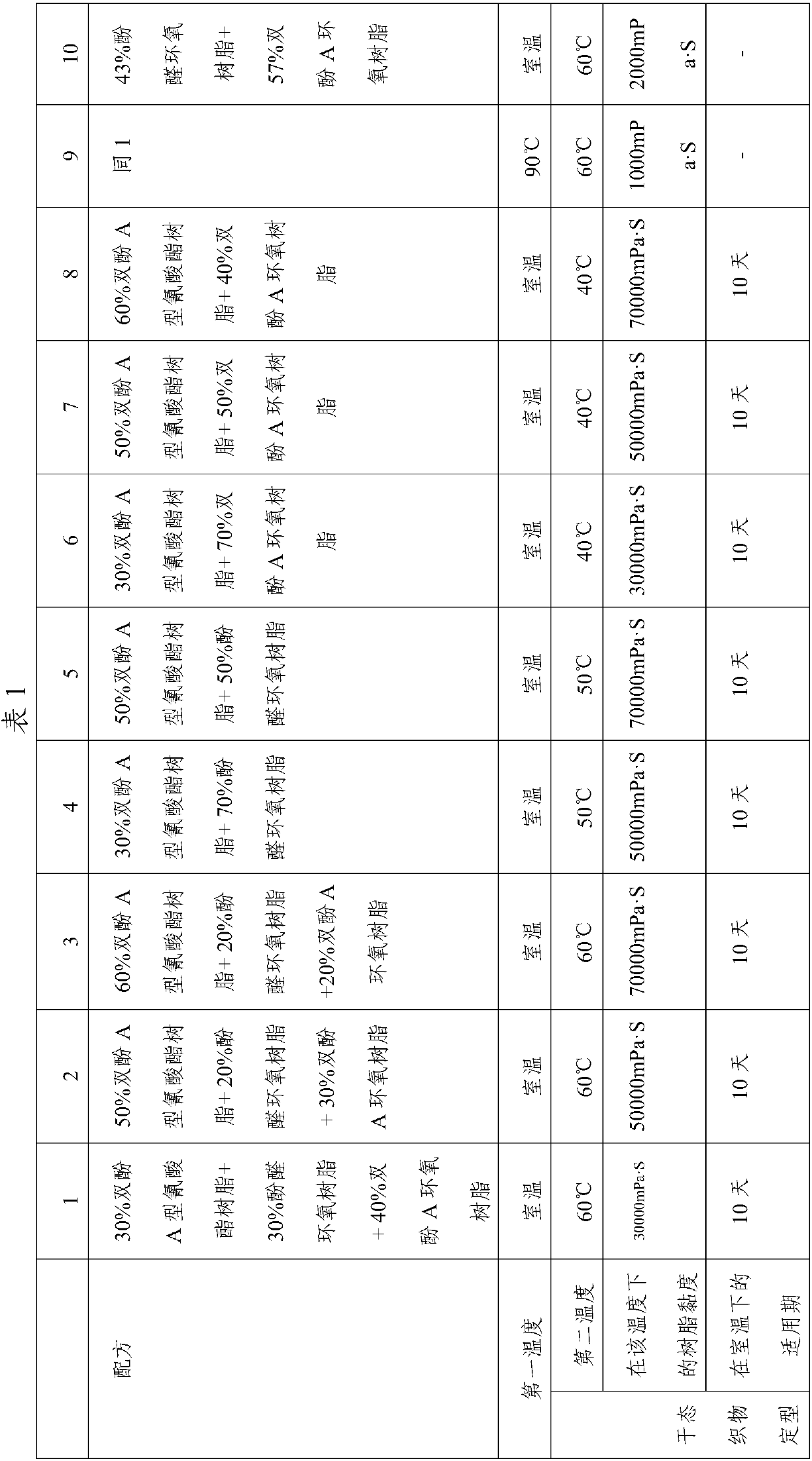

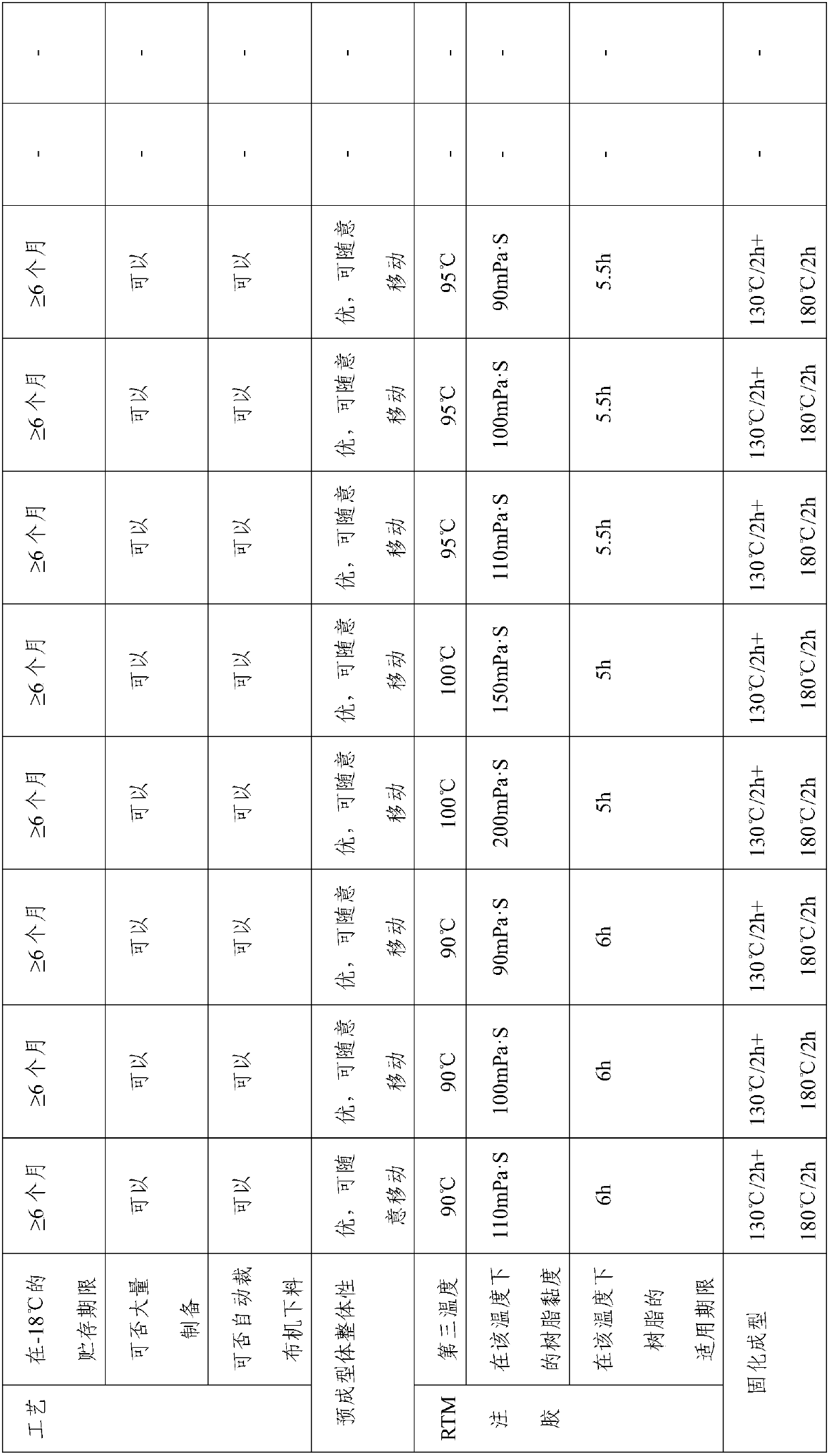

[0048] The preparation raw materials used include: 30% bisphenol A cyanate resin, 30% novolac epoxy resin and 40% bisphenol A epoxy resin. It should be noted that the percentage content here refers to the percentage of the mass of the components in the total mass of the raw materials for preparation. The percentages mentioned below (including Table 1) all have this meaning.

[0049] Dry fabric selection: G0827 unidirectional carbon fiber fabric with an area density of 165g / m 2 , fiber type T300-3k.

[0050] The above-mentioned bisphenol A type cyanate resin and epoxy resin were fully stirred evenly at room temperature with a double planetary mixer. Grind the mechanically stirred resin system through a three-roll mill, control the resin temperature not to exceed 60°C, minimize the melting of cyanate powder, and make the bisphenol A cyanate resin uniformly dispersed in the form of solid powder in the epoxy resin. in the resin. Grind three times to obtain a bisphenol A cyanat...

Embodiment 9

[0054] The preparation raw materials used are the same as in Example 1, and the production method is different from Example 1 as follows: the first temperature is 90°C.

Embodiment 10

[0056] The preparation raw materials used are different from those in Example 1, and there are the following differences: 43% novolac epoxy resin+57% bisphenol A epoxy resin, excluding cyanate resin. Production method with reference to Example 1.

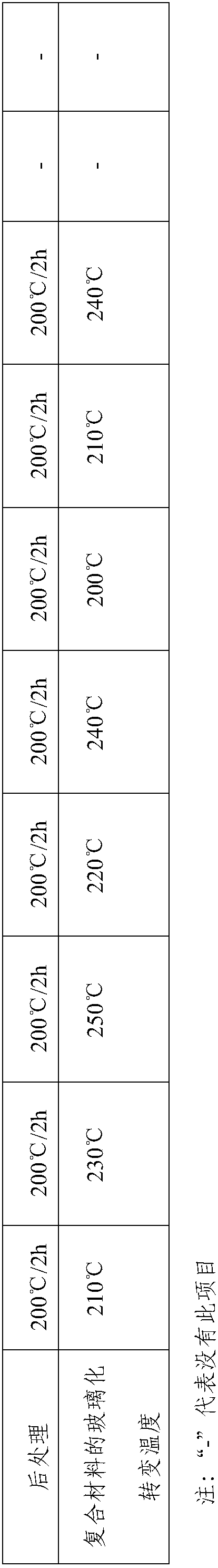

[0057] The application effects of the above-mentioned embodiments were evaluated, and the results are shown in Table 1. As can be seen from Table 1, for the bisphenol A type cyanate ester / epoxy resin system of different proportions, as long as the mixing temperature (i.e. the first temperature) and the dispersion temperature (i.e. the second temperature) are well controlled, the reduction of bisphenol The melting amount of A-type cyanate, so that part or all of bisphenol A-type cyanate is dispersed in the epoxy resin in the form of solid powder, and a one-component RTM epoxy that is solid or semi-solid at room temperature can be obtained. Resin system can meet the batch setting processing requirements of dry fabrics. When the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com