Intensified smelting method and system for calcium carbide

A smelting method and calcium carbide technology, applied in the field of calcium carbide intensified smelting methods and systems, can solve problems such as the complexity of oxygen supply devices, achieve the effects of saving power consumption, preventing local overcooling, and reducing the cost of calcium carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

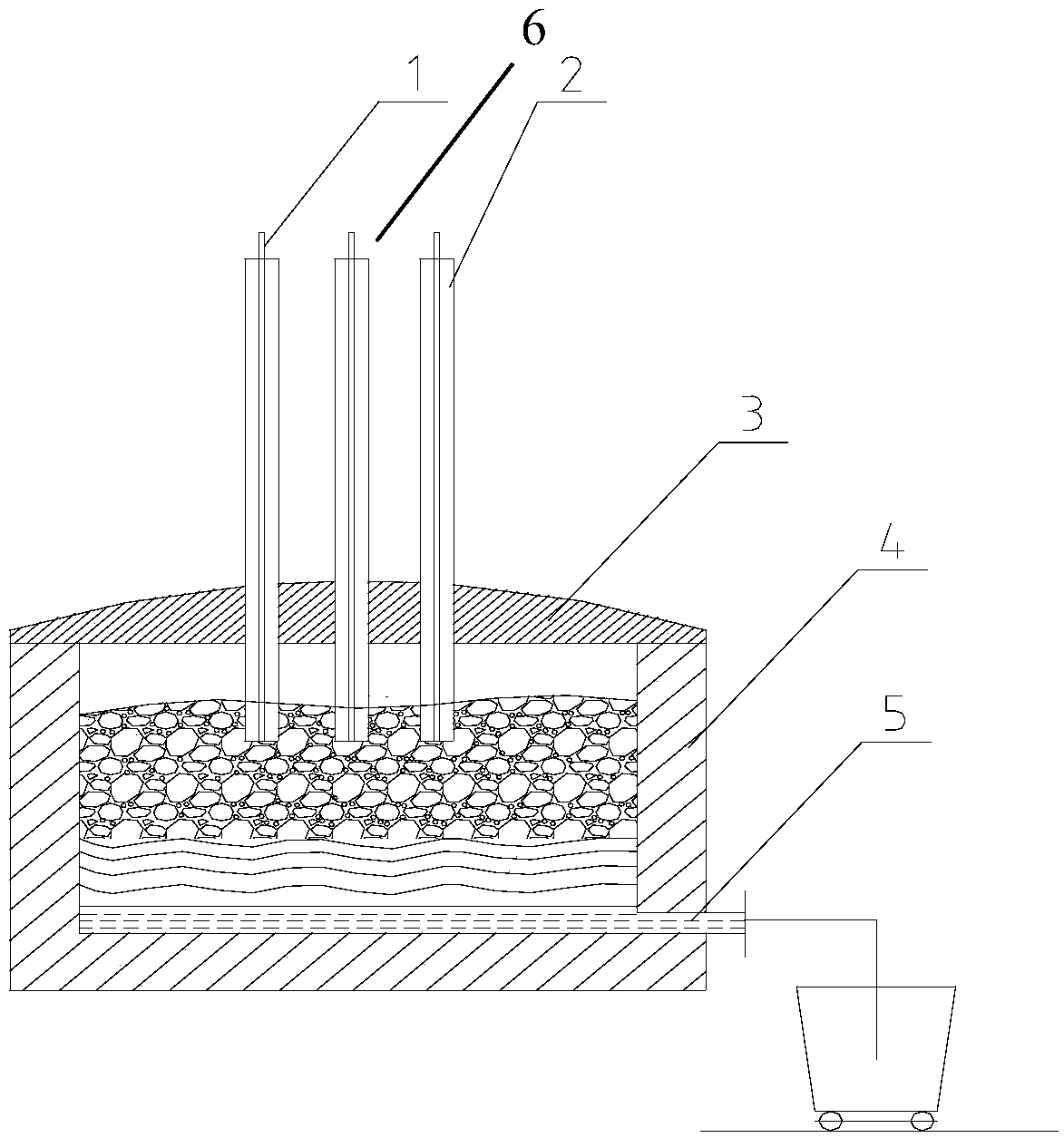

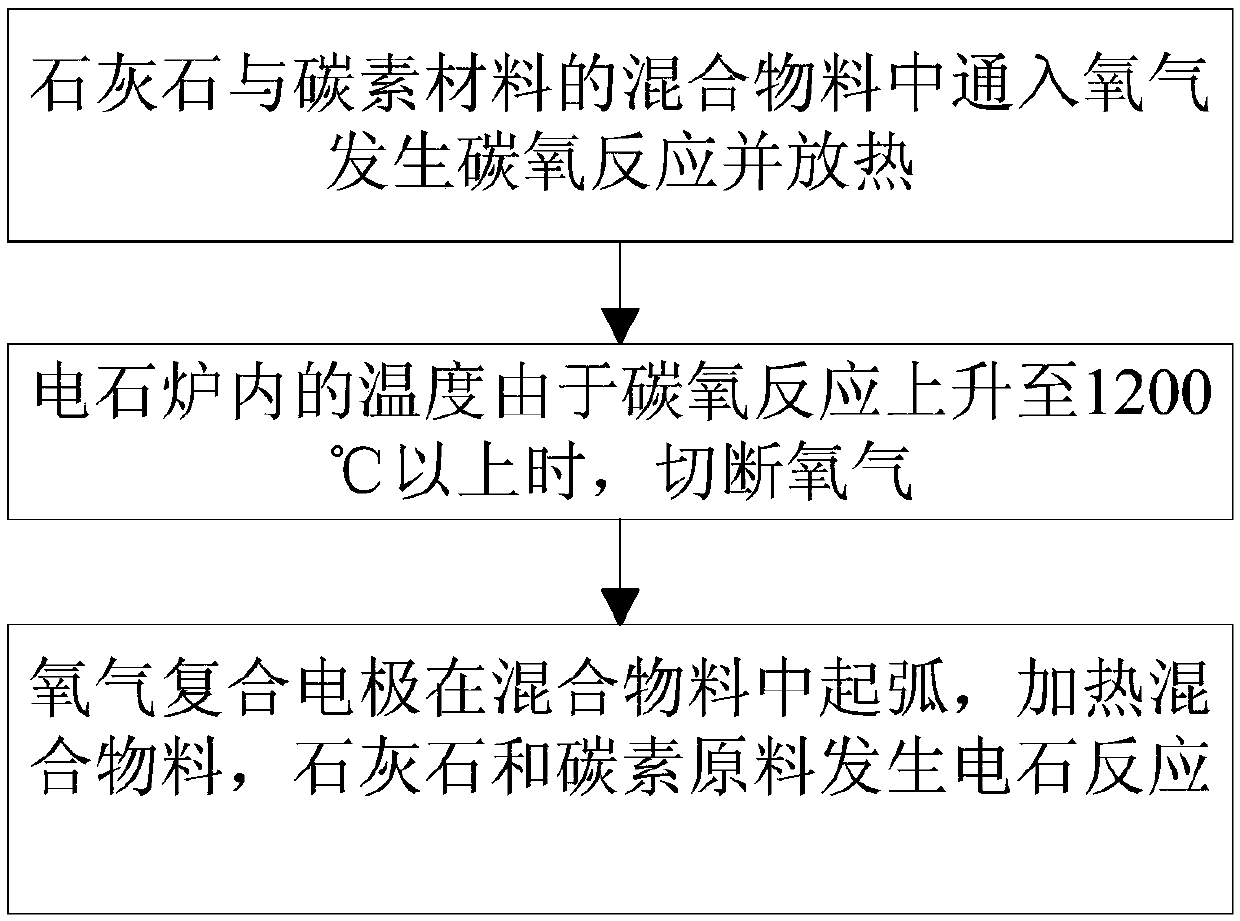

Embodiment 1

[0067] CaO / C mass ratio is 5: 3 limestone and carbonaceous material (the present embodiment is carbon black) enters in the furnace body 4 of calcium carbide furnace through feeding device, and oxygen compound electrode 6 descends and inserts in the mixed material, opens oxygen valve Feed in pure oxygen (oxygen content = 100%), oxygen is sprayed out from the oxygen tube 1 at a certain speed, in this process, the flow rate of oxygen in the tube is controlled at: 60m / s, and the CO / CO 2 for 3. The oxygen tube 1 is a seamless steel pipe, and the hollow electrode 2 is a graphite electrode. Oxygen reacts with part of the carbon raw material in the furnace body 4 to release a large amount of heat, and the CO gas generated at the same time causes the stirring and stirring of the mixed material, and the mixed material is heated to 1200° C., and the oxygen supply is stopped. When the power is turned on, an electric arc is generated between the oxygen composite electrode 6 and the mixed ...

Embodiment 2

[0069] CaO / C mass ratio is 8: 4 limestone and carbonaceous material (the present embodiment is activated carbon) enters in the furnace body 4 of calcium carbide furnace through feeding device, and oxygen composite electrode 6 descends and inserts in the mixed material, opens oxygen valve to pass through Enter oxygen-enriched air (oxygen content ≥ 80%), and the oxygen-enriched air is ejected from the oxygen tube 1 at a certain speed. CO 2 for 4. The oxygen tube 1 is a ceramic tube, and the hollow electrode 2 is a graphite electrode. Oxygen-enriched air reacts with some carbon raw materials in the furnace body 4 to release a large amount of heat. At the same time, the generated CO gas causes the stirring and stirring of the mixed material. The mixed material is heated to 1300° C., and the supply of oxygen-enriched air is stopped. When the power is turned on, an electric arc is generated between the oxygen composite electrode 6 and the mixed material, and the temperature of the...

Embodiment 3

[0071] Limestone and carbon material (graphite in this embodiment) with a mass ratio of CaO / C of 6:3 enter into the furnace body 4 of the calcium carbide furnace through the feeding device, the oxygen composite electrode 6 is lowered and inserted into the mixed material, and the oxygen valve is opened to pass through Inject pure oxygen, and the oxygen is ejected from the oxygen tube 1 at a certain speed. During this process, the flow rate of the oxygen in the tube is controlled at 50m / s, and the CO / CO 2 for 3. The oxygen tube 1 is a ceramic tube, and the hollow electrode 2 is a graphite electrode. Oxygen reacts with part of the carbon raw materials in the furnace body 4 to release a large amount of heat, and the generated CO gas causes the stirring and stirring of the mixed material, and the mixed material is heated to 1250° C., and the oxygen supply is stopped. When the power is turned on, an electric arc is generated between the oxygen compound electrode 6 and the mixed mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com