Method for producing cyclohexyl acetate through reaction rectification

A technology of cyclohexyl acetate and reactive distillation, which is applied in the field of reactive distillation to prepare cyclohexyl acetate, can solve the problems of high cost, unsuitability for large-scale industrial production, and low output, so as to prolong life, avoid side reactions, The effect of reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

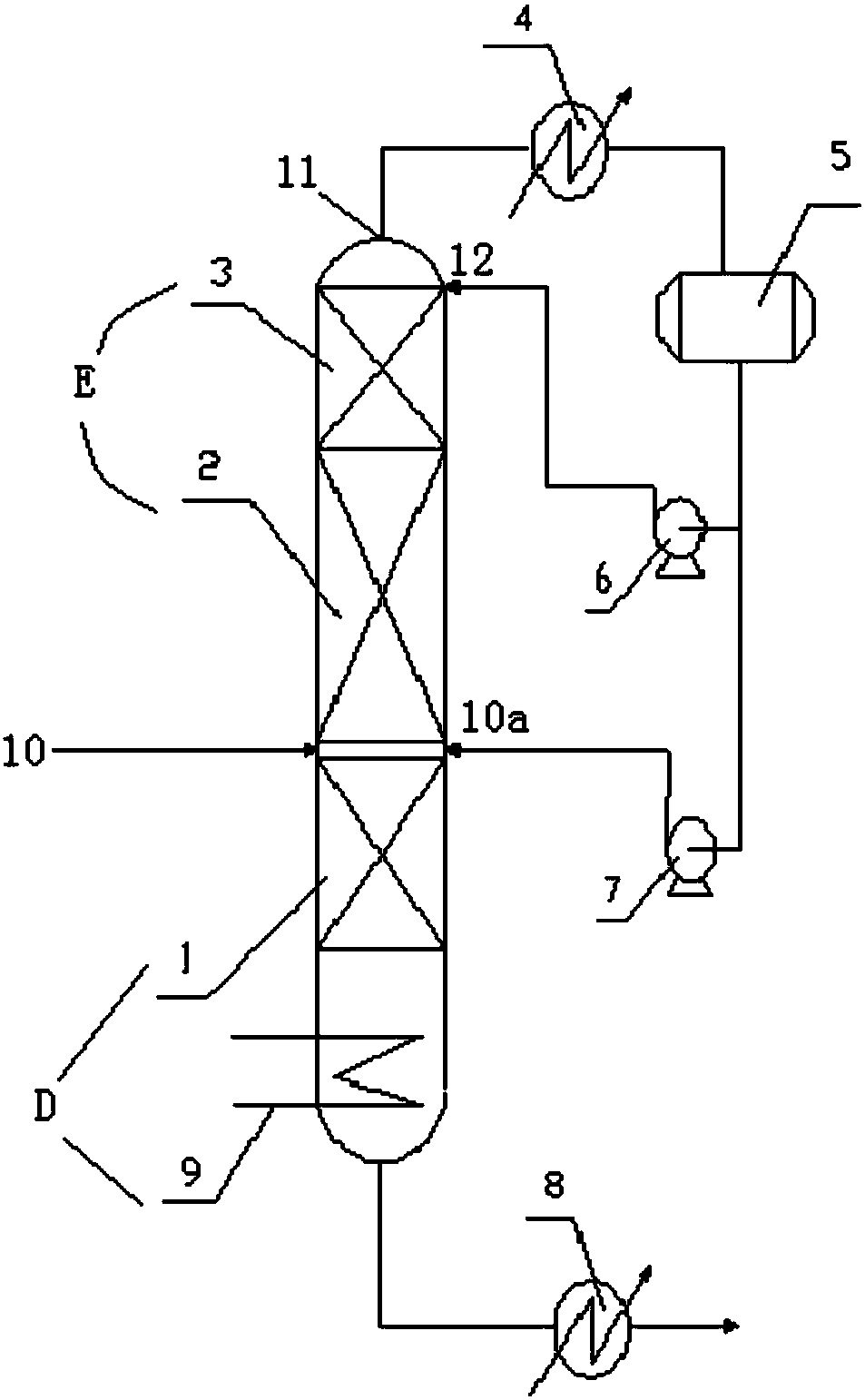

Image

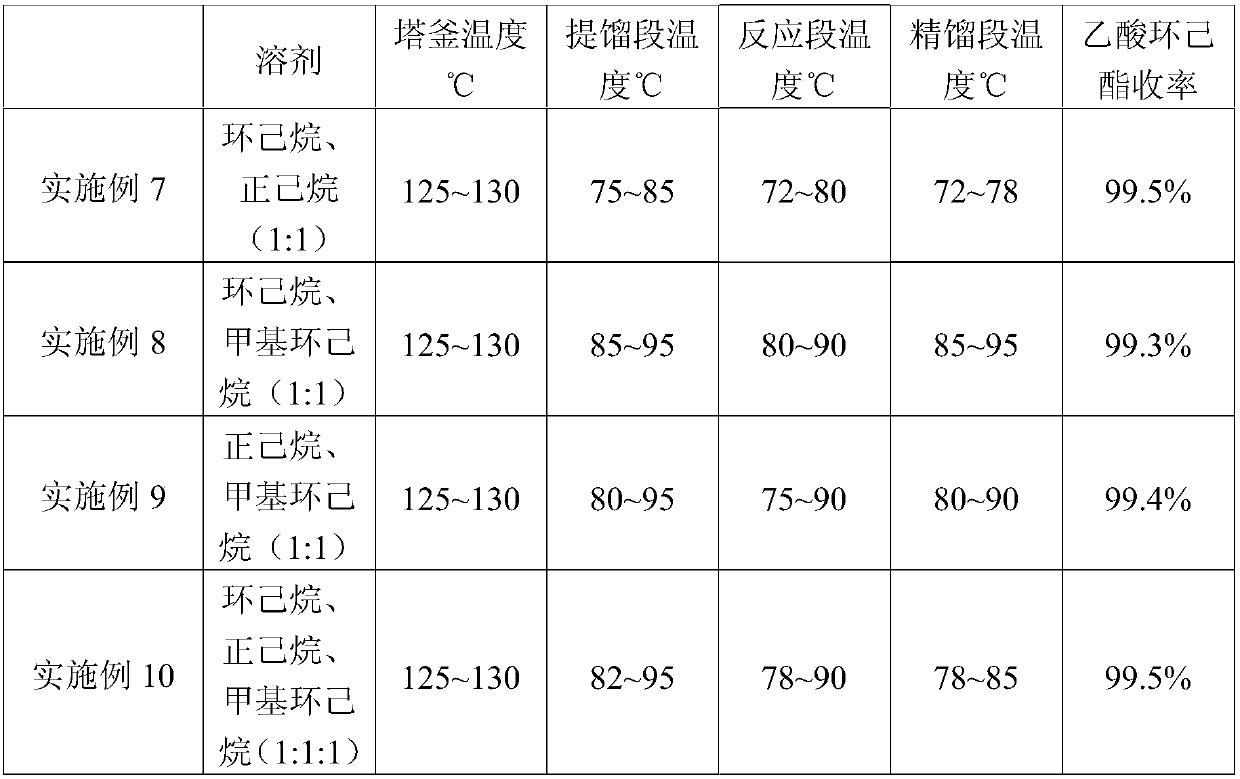

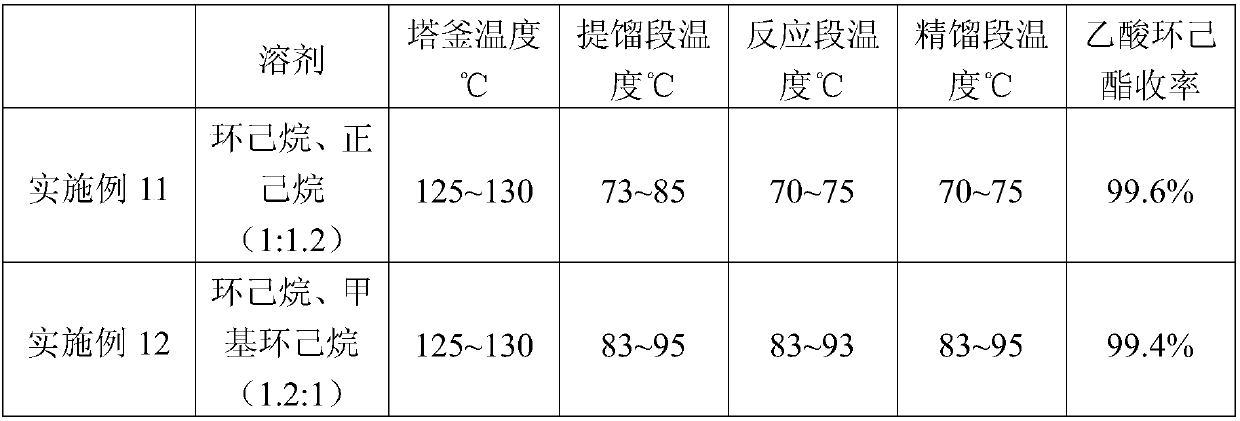

Examples

Embodiment 1

[0044] In this process, the circulating mass flow rate of the solvent divided by the raw material feed mass flow rate is set to 1;

[0045] Reactive distillation column start-up test

[0046] step one

[0047] Under normal pressure, add solvent hexanaphthene from feed inlet 10, set up tower still liquid level 60%, tower still heats up, set up tower top reflux tank 5 cyclohexane liquid level 40%, start tower top reflux pump 6, tower top The cyclohexane pumped back by the reflux pump 6 enters the rectifying section 3 through the second interface 12 and establishes a total reflux of the reactive distillation tower, with a reflux rate of 4 kg / h;

[0048] step two

[0049] Add acetic acid from the feed port (10) at a flow rate of 3kg / h, and gradually increase the temperature of the tower kettle to 118°C, the temperature of the stripping section is 90°C, and the temperature of the reaction section and rectification section is 79-81°C;

[0050] step three

[0051] Control cyclohe...

Embodiment 2

[0053] In this process, the circulating mass flow rate of the solvent divided by the raw material feed mass flow rate is set to 3;

[0054] Reactive distillation column start-up test

[0055] The first step: under normal pressure, add cyclohexane from the first feed port, establish the liquid level of the tower kettle to 60%, raise the temperature of the tower kettle, set up the top reflux tank 5 cyclohexane liquid level 50%, start the top reflux pump 6. The cyclohexane pumped back by the tower top reflux pump 6 enters the rectification section 3 through the second interface 12 and establishes a total reflux of the reactive distillation column with a reflux rate of 10kg / h;

[0056] The second step: add acetic acid from the feed port (10) at a flow rate of 5kg / h, gradually increase the temperature of the tower kettle to 118°C, the temperature of the stripping section is 85°C, and the temperature of the reaction section and rectifying section is 79-81°C.

[0057] The 3rd step: ...

Embodiment 3

[0059] Using n-hexane instead of cyclohexane, the test process is the same as in Example 1. When the device is running stably, in step 3, the temperature of the tower kettle is 125°C, the temperature of the stripping section is 78°C, the temperature of the reaction section is 73-75°C, and the temperature of the rectifying section is 65°C. ~66°C, continuous operation for 240 hours, the yield of cyclohexyl acetate is greater than 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com