Extraction method for plant condensed tannin high polymers

A technology of condensed tannin and extraction method, which is applied in the field of extraction and purification of plant tannin, can solve the problems of research and application limitations, difficulty of condensed tannin, etc., and achieve the effects of maintaining biological activity, improving purity, and good step repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

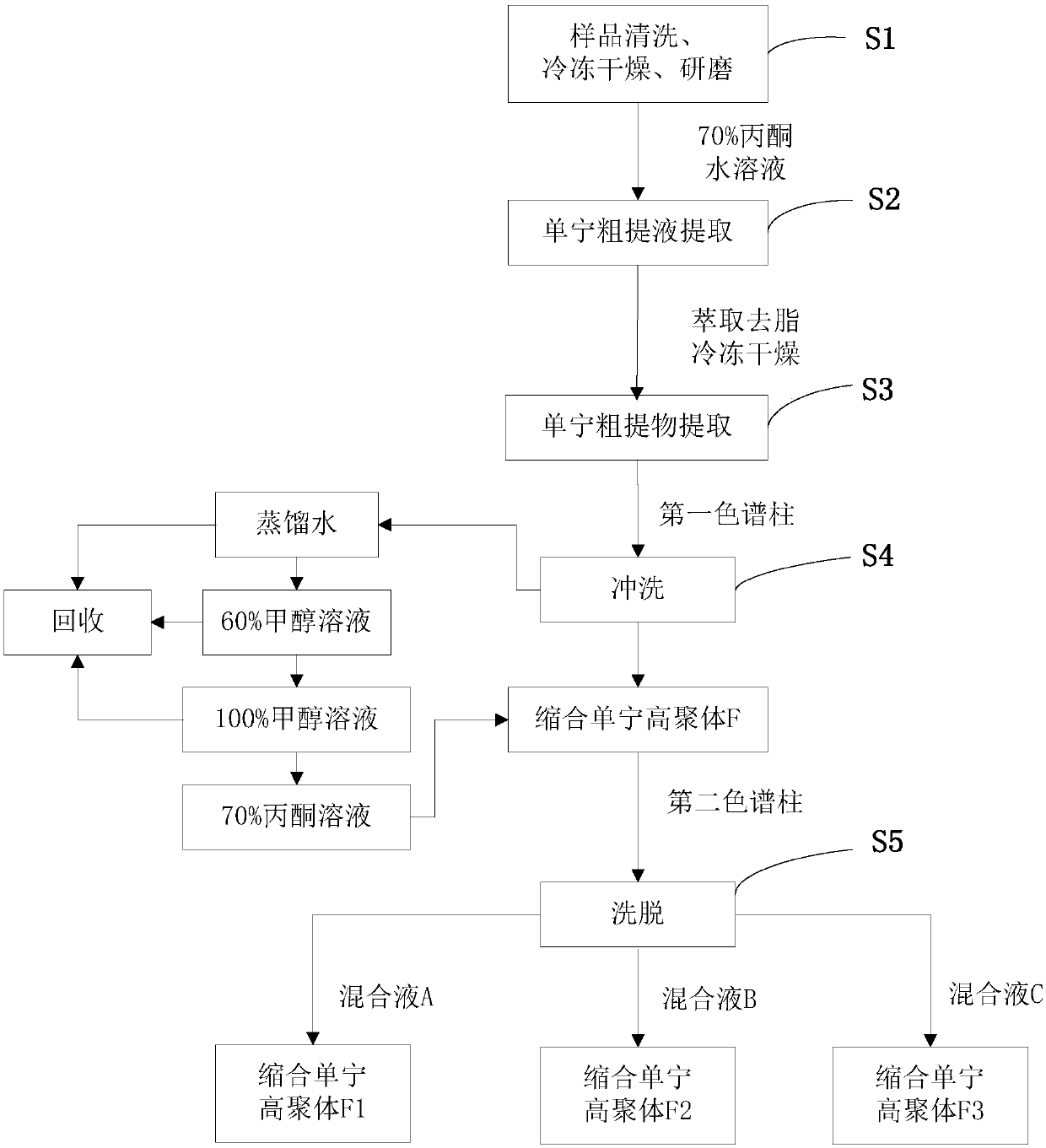

[0045] see figure 1 , this embodiment takes the mangrove plant silique as the implementation object, and is used to extract the condensed tannin polymer in the mangrove plant.

[0046] S1 Select an appropriate amount of mature leaves of Mangroveaceae, put them into a freeze dryer, freeze-dry them at a temperature of -40 to -50°C for more than 72 hours, and then grind them evenly with a mortar;

[0047] S2 Take 100 g of the above-mentioned ground sample, add 500 mL of 70% acetone aqueous solution, conduct ultrasonic extraction for 30 min, and then centrifuge at a centrifugation rate of 19000 g. Then the supernatant was collected, and 70% acetone aqueous solution was added to the remaining precipitated part, followed by ultrasonic extraction and centrifugation. The above process was carried out three times in total.

[0048] The supernatants obtained from the above three centrifugation treatments were combined, and rotary evaporated at a temperature not higher than 30° C. to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com