Anti-wrinkling and antibacterial cotton fabric finishing agent and preparation method thereof

A technology of fabric finishing agent and antibacterial cotton, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc. It can solve the problems of clothes turning yellow, poor hand feeling, poor antibacterial effect, etc., and achieve enhanced anti-wrinkle performance, comfortable hand feeling and performance damage low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

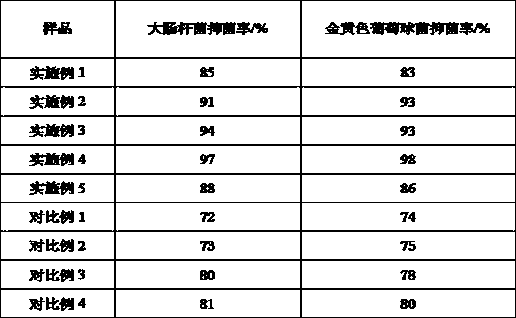

Examples

Embodiment 1

[0056] Get 4 parts of Veratrum ethanol extract, 3 parts of Anemarrhena 50wt% ethanol water extract, 8 parts of Chonglou water extract, 5 parts of methyl carbamate, 12 parts of cyclopentane tetracarboxylic acid, 3 parts of furfural resin, 9 parts of dimethylacetamide, 9 parts of 4,4-diaminodiphenylmethane tetraglycidylamine, 2 parts of sodium hydrogen phosphate, and 20 parts of water, mix and stir the above-mentioned components, and prepare the anti-aging compound after stirring for 15 minutes. Wrinkle antibacterial cotton fabric finish.

Embodiment 2

[0058] Get 7 parts of Veratrum ethanol extract, 5 parts of Anemarrhena 50wt% ethanol water extract, 6 parts of Chonglou water extract, 7 parts of methyl carbamate, 11 parts of cyclopentane tetracarboxylic acid, 7 parts of furfural resin, 4 parts of dimethylacetamide, 8 parts of 4,4-diaminodiphenylmethane tetraglycidylamine, 6 parts of sodium hydrogen phosphate, 12 parts of water, mix and stir the above-mentioned components, and prepare after stirring for 15 minutes Anti-crease antibacterial cotton fabric finish.

Embodiment 3

[0060] Get 12 parts of Veratrum ethanol extract, 9 parts of Anemarrhena 50wt% ethanol water extract, 3 parts of Chonglou water extract, 10 parts of methyl carbamate, 8 parts of cyclopentane tetracarboxylic acid, 4 parts of furfural resin, 8 parts of dimethylacetamide, 4 parts of 4,4-diaminodiphenylmethane tetraglycidylamine, 3 parts of sodium hydrogen phosphate, and 18 parts of water, mix and stir the above-mentioned components, and prepare the antibacterial compound after stirring for 15 minutes. Wrinkle antibacterial cotton fabric finish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com