Preparation method of adhesive-free polymerized colorful emulsion particles used for inkjet printing

An inkjet printing, adhesive-free technology, applied in the fields of fine chemicals and materials science, can solve problems such as complex processes and achieve the effect of improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

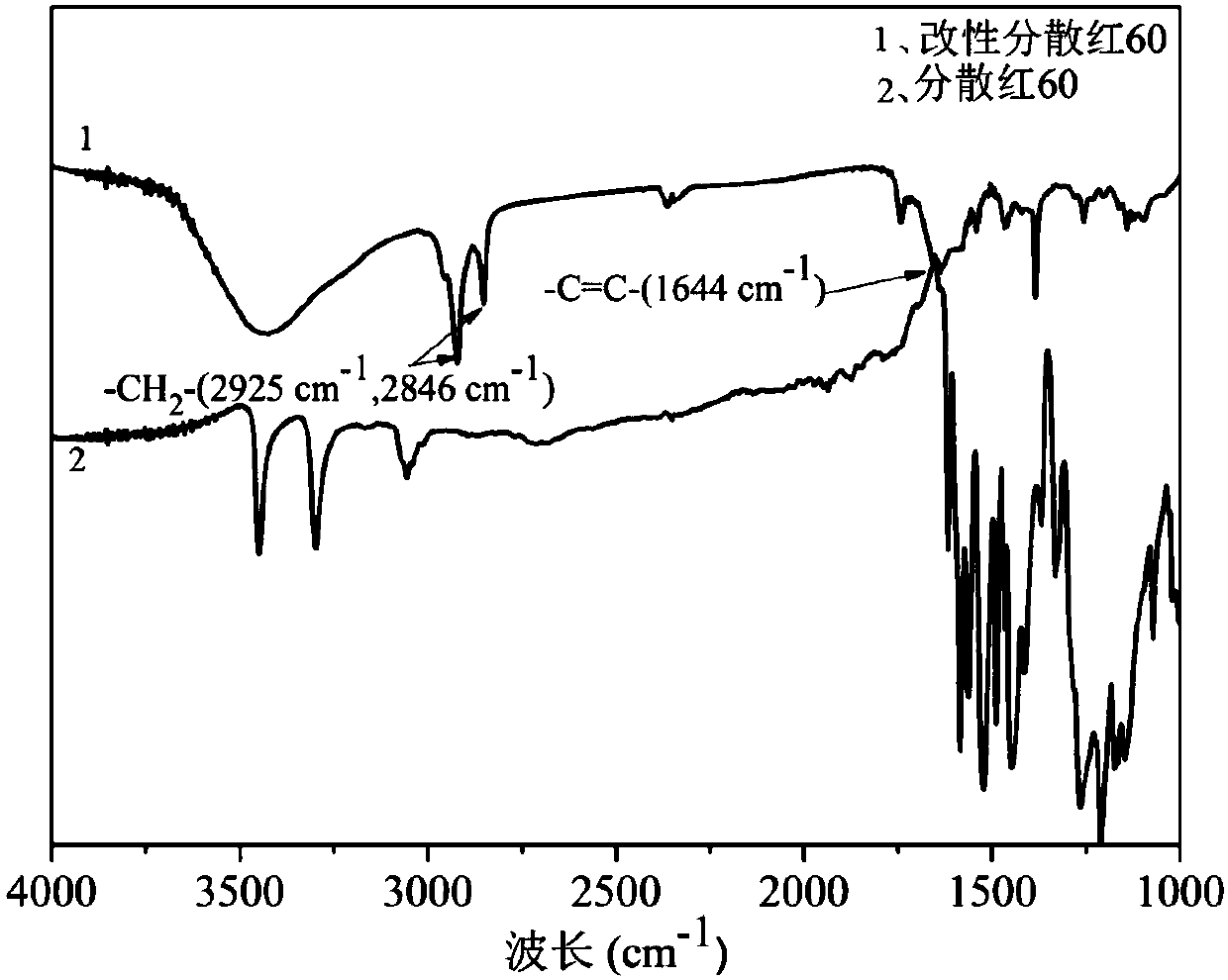

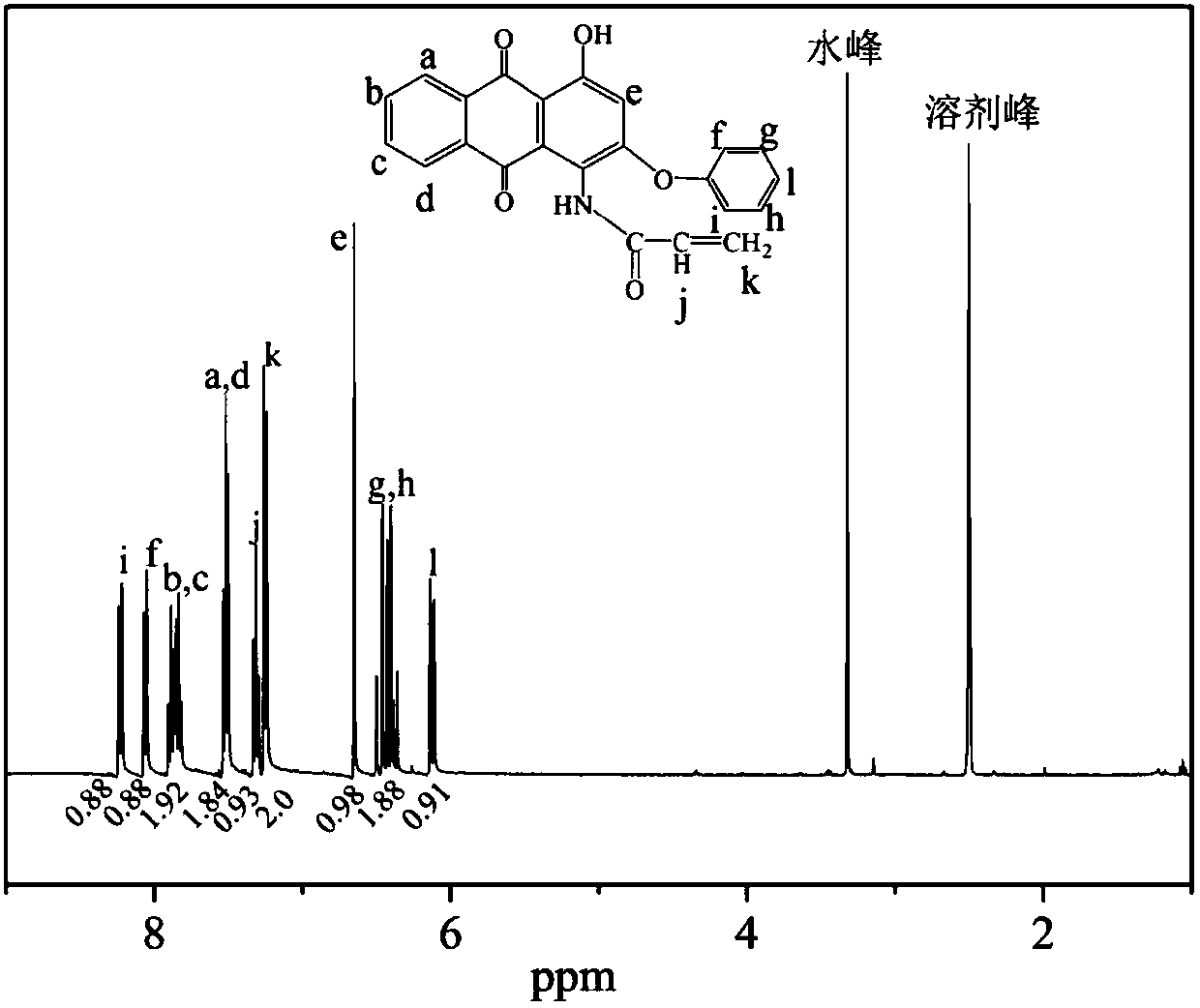

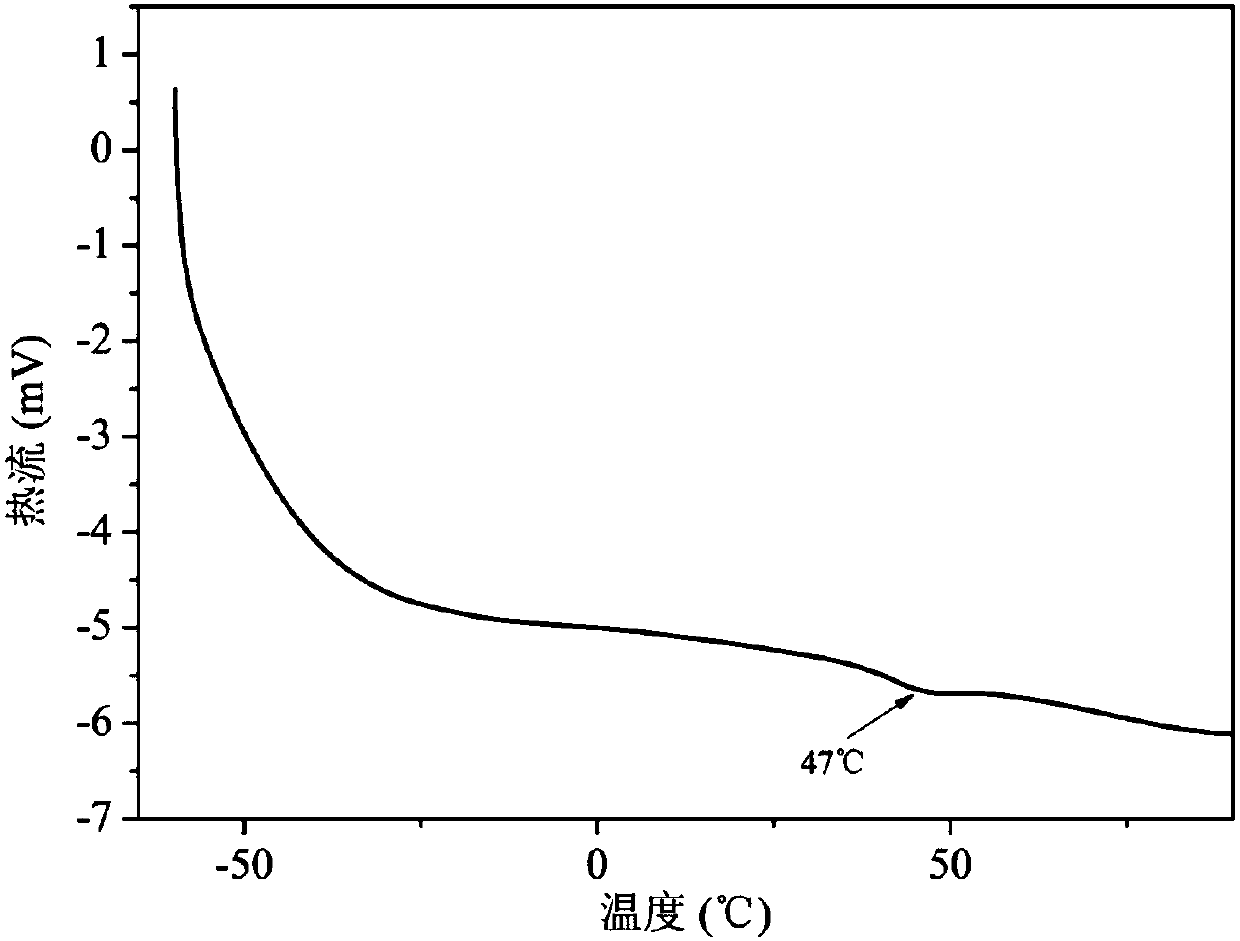

[0030] Dissolve 8.28 g (0.025 mol) of Disperse Red 60 and 3.5 ml (0.025 mol) of triethylamine in a reaction flask with 20 mL of tetrahydrofuran. A mixed solution of 3.62 g of acryloyl chloride (0.04 mol) and 10 ml of tetrahydrofuran was slowly added dropwise with a constant pressure dropping funnel under the condition of an ice bath. React in an ice bath for 5h, monitor the whole reaction process with thin-layer chromatography, the developer used is 1:8 ethyl acetate / petroleum ether, fully wash with saturated sodium bicarbonate solution after the reaction, and precipitate to obtain crude product, the obtained crude product was fully washed with absolute ethanol to obtain a red powdery solid product, which was dried for use. A mixed solution of 5% DNS-86 solution and 0.1125g of co-emulsifier HD was emulsified at high speed to form a uniform dispersion, and then 7.5g of styrene, 7.5g of ethyl acrylate, and 0.225g of modified disperse red 60 were dissolved Then slowly add it to ...

Embodiment 2

[0036] Dissolve 7.45 g (0.025 mol) of disperse blue E-BR and 2.01 mL of pyridine in 20 mL of tetrahydrofuran in a reaction flask. A mixed solution of 4.18 g of methacryloyl chloride (0.04 mol) and 10 mL of tetrahydrofuran was slowly added dropwise using a constant pressure dropping funnel at about 0°C. React in an ice bath for 5h, monitor the whole reaction process with thin-layer chromatography, the developer used is 1:8 ethyl acetate / petroleum ether, fully wash with saturated sodium bicarbonate solution after the reaction, and precipitate to obtain crude product, the obtained crude product was fully washed with absolute ethanol to obtain a blue powdery solid product, which was dried for use. A mixed solution of 10% DNS-86 solution and 0.25g of co-emulsifier CA was emulsified at high speed to form a uniform dispersion, and then 3.75g of methyl methacrylate, 7.5g of methyl acrylate, and 0.4g of modified After the blue E-BR dissolves, slowly add it to the prepared above soluti...

Embodiment 3

[0038] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Similar to Example 1, the difference is that the amount of the modified pigment molecule is 0.03 g, and the mass ratio of the hard monomer and the soft monomer is changed to 1.2:1. The particle size of the prepared colored latex particles is about 200nm. Latex particles have good film-forming properties, and the printing fastness is grade three.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com