Self-resetting frame-shear wall structure for reinforcing earthquake-damaged frame and construction method

A shear wall and self-resetting technology, which is applied to walls, earthquake resistance, building components, etc., can solve problems such as structural damage and non-structural component damage, and achieve the effects of low earthquake damage, reduced earthquake-induced damage, and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

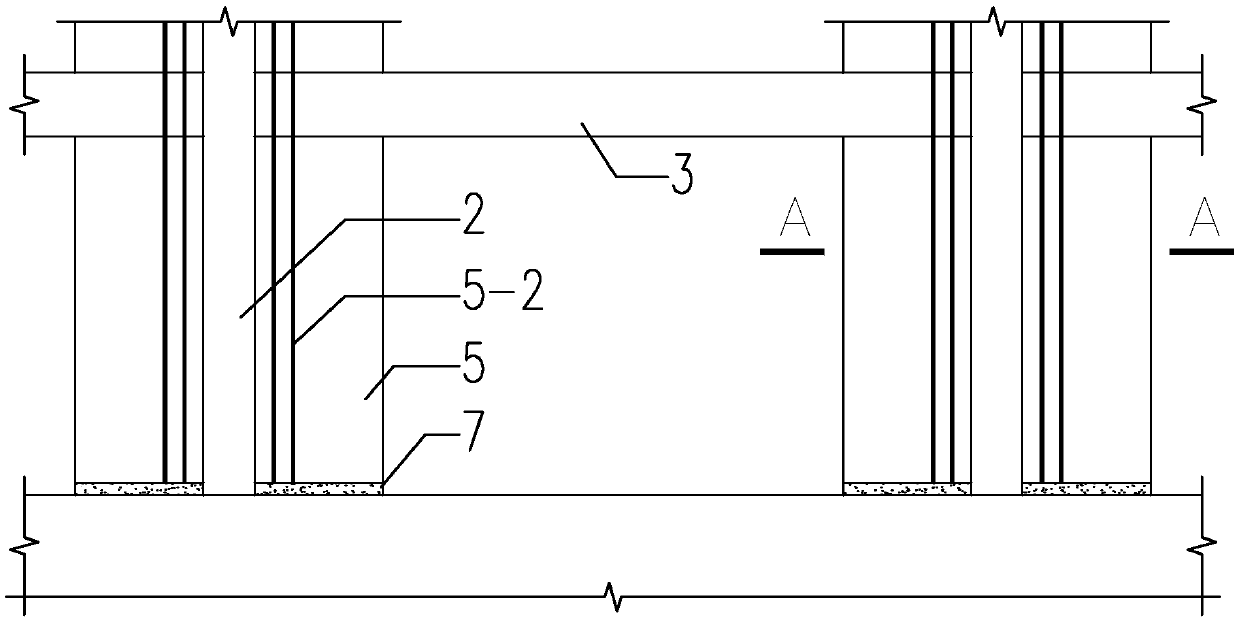

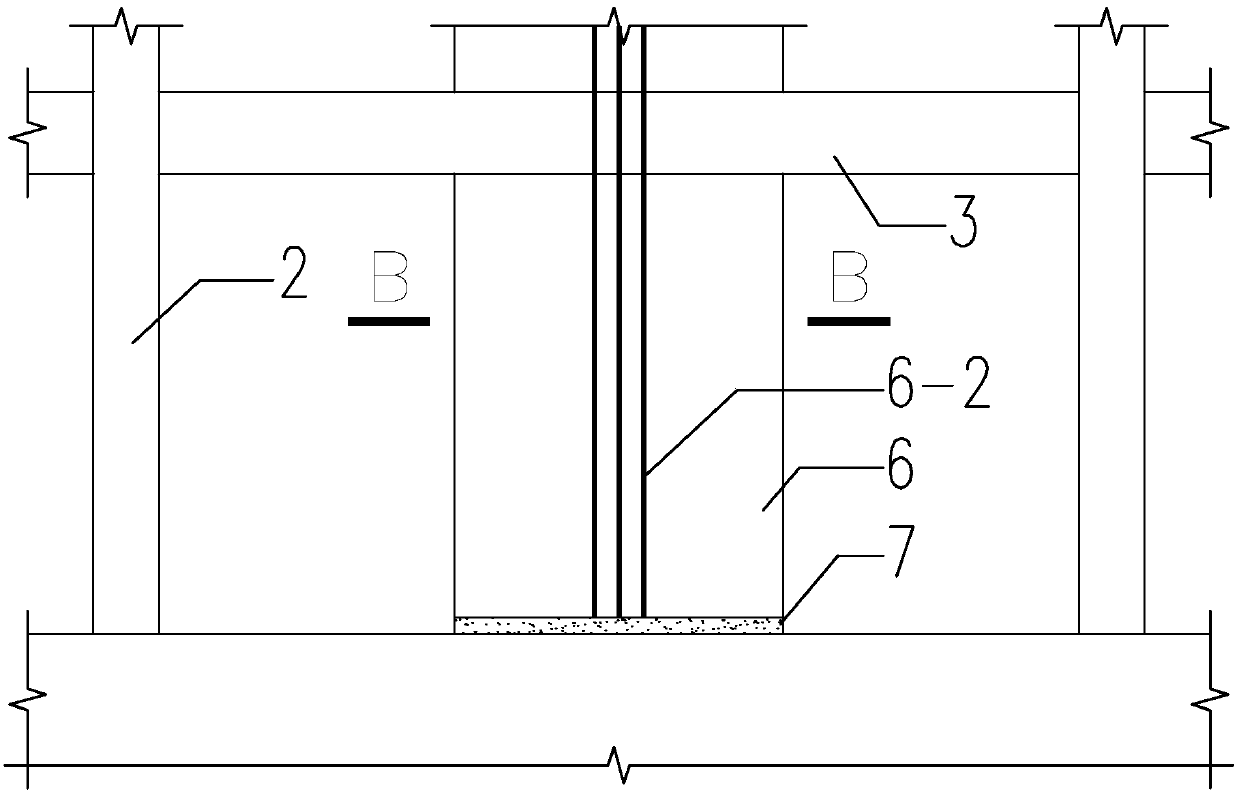

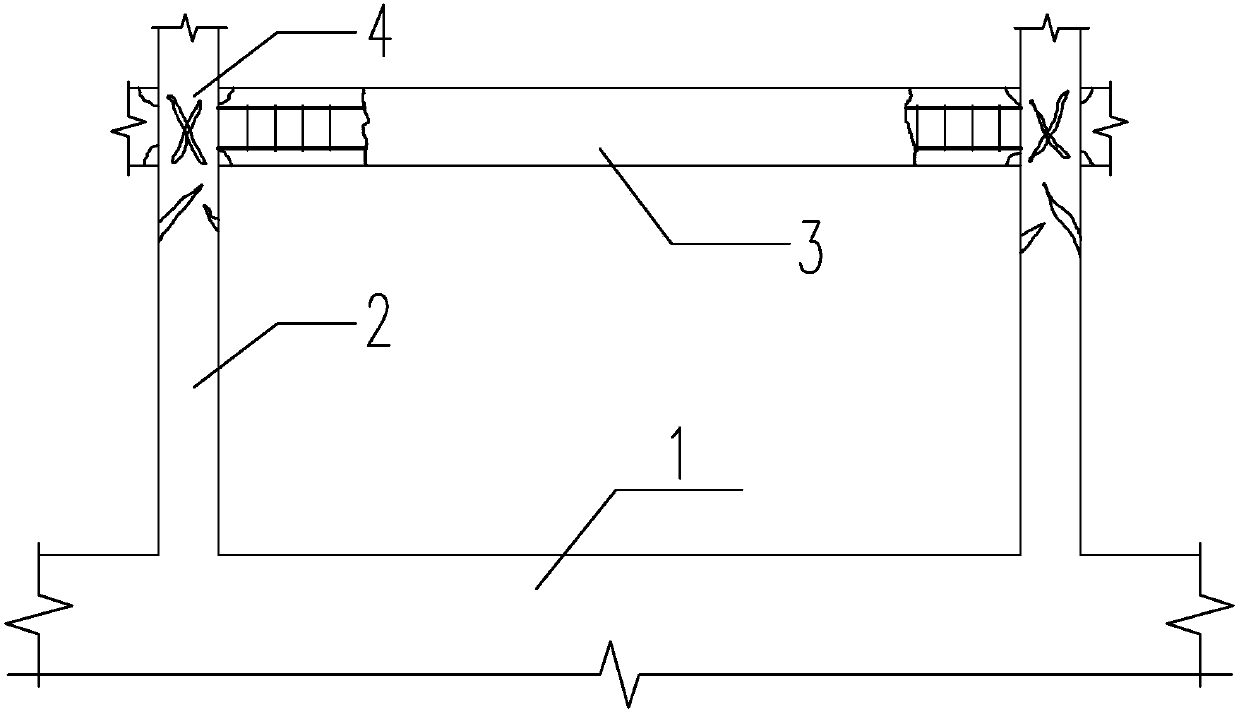

[0046] Specific implementation mode one: combine figure 1 , Figure 3 to Figure 8 and Figure 10 Describe this embodiment, a self-resetting frame-shear wall structure for strengthening the earthquake-damaged frame described in this embodiment includes an earthquake-damaged frame 1, frame columns 2, frame beams 3 and beam-column nodes 4; it also includes multiple Rear shear walls 5 on the column side and fiber cement slurry layer 7, multiple rear shear walls 5 on the column side are arranged symmetrically or on three sides or four sides and installed on the frame column 2, and the rear shear walls 5 on the column side A certain height is reserved at the bottom, and the fiber cement slurry layer 7 is formed by pressure filling within the reserved height range. The reserved height is 25mm-35mm, and the post shear wall 5 is placed on the side of the column on multiple frame column sides within the structural plane range. Arranged as needed, spanning multiple layers in the vertic...

specific Embodiment approach 2

[0049] Specific implementation mode two: combination figure 1 , Figure 7 , Figure 8 and Figure 10 Describe this embodiment, each column-side rear shear wall 5 in this embodiment includes multiple column-side tunnels 5-1, multiple column-side prestressed tendons 5-2, and multiple column-side lower anchors 5-3 , multiple anchors 5-4 on the column side, 5-5 multiple pin key reinforcement bars on the column side, 5-6 vertically distributed reinforcement bars on the column side, 5-7 horizontally distributed reinforcement bars on the column side, and 5 multiple energy-dissipating reinforcement bars on the column side -11; the column side channel 5-1 is vertically arranged parallel to the height direction of the frame column 2, the column side prestressed tendons 5-2 are pierced in the column side channel 5-1, and the lower end of the column side prestressed tendons 5-2 passes through The lower anchor 5-3 on the column side is anchored below the fiber cement slurry layer 7 at t...

specific Embodiment approach 3

[0050] Specific implementation mode three: combination figure 1 , Figure 7 , Figure 8 and Figure 10 To illustrate this embodiment, each column-side rear shear wall 5 of this embodiment also includes column-side tie bars 5-8, column-side edge-constrained longitudinal reinforcements 5-9 and column-side edge-constrained area stirrups 5- 10. The tie bars 5-8 on the column side are arranged at an interval of no more than 600mm in the horizontal direction and the vertical direction, and the double-row reinforcement mesh formed by the vertically distributed steel bars 5-6 on the column side and the horizontally distributed steel bars 5-7 on the column side The bottom of vertically distributed steel bars 5-6 on the column side and the longitudinal bars 5-9 in the restricted area on the edge of the column do not extend into the foundation, and the vertically distributed steel bars 5-6 on the column side and the top of longitudinal bars 5-9 in the restricted area on the edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com