Stacked capacitor

A technology of multilayer capacitors and protective layers, applied in the direction of multilayer capacitors, etc., can solve the problem of easy vulcanization of silver materials, and achieve the effect of good anti-vulcanization effect, reliability and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

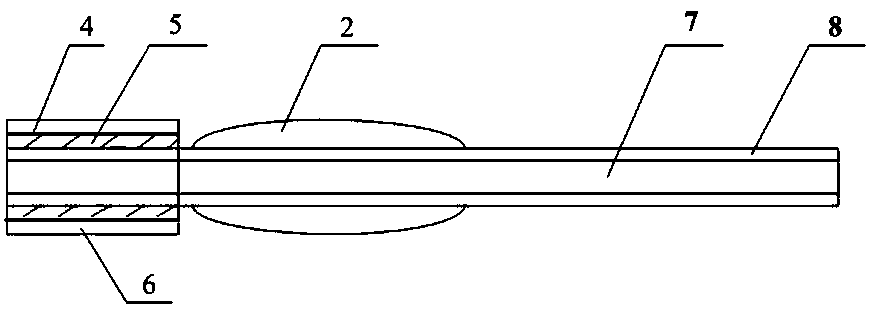

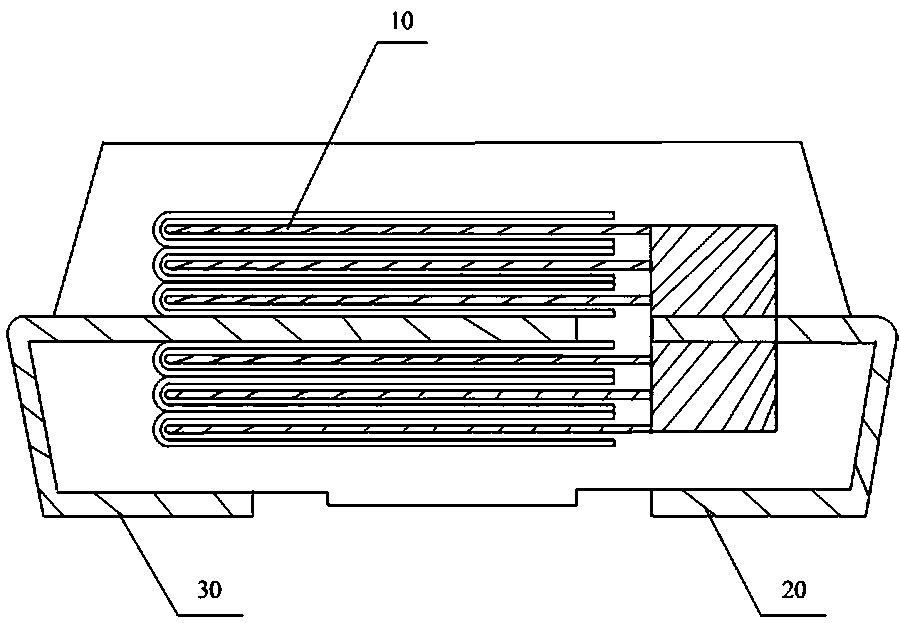

[0030] Such as Figure 6 and Figure 7 As shown, the first embodiment of the present invention proposes a multilayer capacitor proposed by the present invention, which includes a plurality of laminated cells 10, and a positive lead-out terminal 20 and a negative lead-out terminal 30 electrically connected to the cell 10, each The sheet monomer 10 includes a positive end 11, a negative end 12, and a shielding adhesive wire 13 between the positive end 11 and the negative end 12; the negative ends 12 of each sheet monomer 10 are connected together and connected to the negative lead-out terminal 30; The positive ends 11 of the single cells 10 are connected together and connected to the positive lead-out terminal 20. The negative end 12 of each single cell 10 includes a dielectric film 121, a solid electrolyte layer 122, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com