Nerve conduit with silk fibroin nanofiber directional guiding function and preparation method of nerve conduit

A silk fibroin and nanofiber technology, applied in the field of nerve conduits, can solve the problem of not having three-dimensional micro-nano guiding signals, and achieve the effect of a simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Soak 100g silkworm raw silk in 5L of 0.05% Na 2 CO 3 In the solution, boil at 98-100°C for 30min, repeat 3 times to degumming the silk, wash and dry it thoroughly to obtain pure silk fiber; add the silk fiber to 9.3mol / L LiBr solution, at 60°C Stir and dissolve for 1 hour to obtain a silk fibroin mixed solution; put the obtained silk fibroin mixed solution into a dialysis bag, and dialyze with deionized water for 3 days to obtain a purified silk fibroin solution;

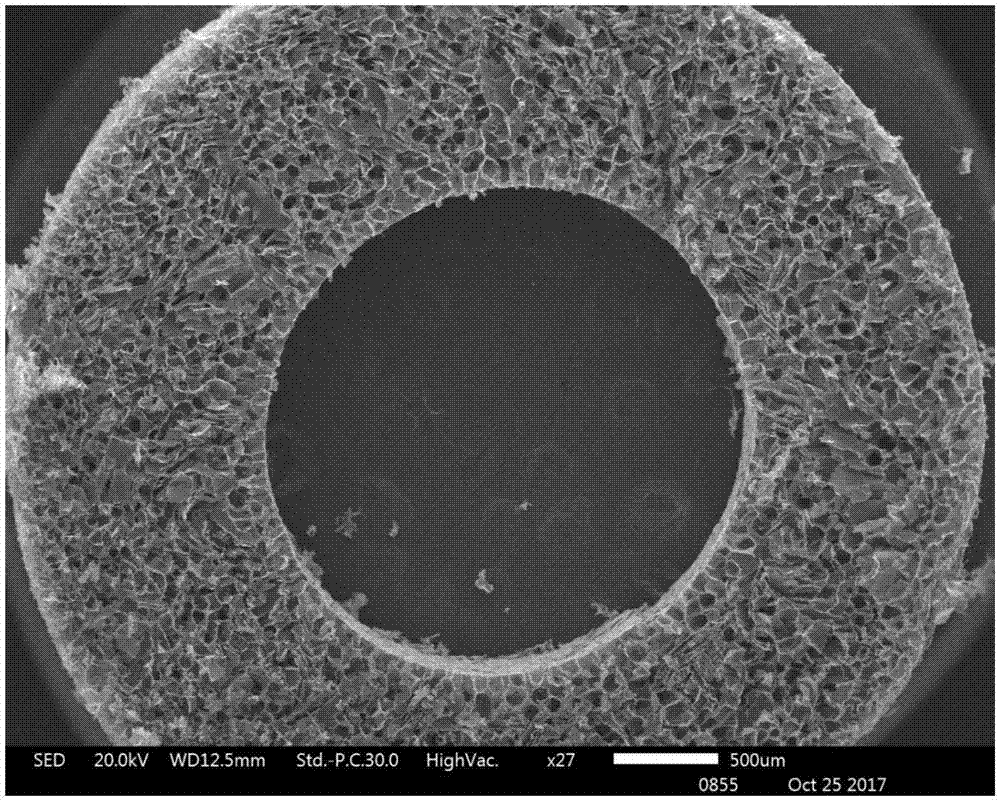

[0028] Adjust the mass concentration of silk fibroin solution to 5%, pour it into the nerve guide mold, freeze at -80°C for 24h to form a frozen solid silk fibroin, then place it at -4°C for 3 days to induce the structural transformation of silk fibroin, and then Freeze-drying was carried out to obtain the outer layer catheter.

[0029] According to the method disclosed in patent CN106421902A, a rapidly gelled silk fibroin solution is prepared.

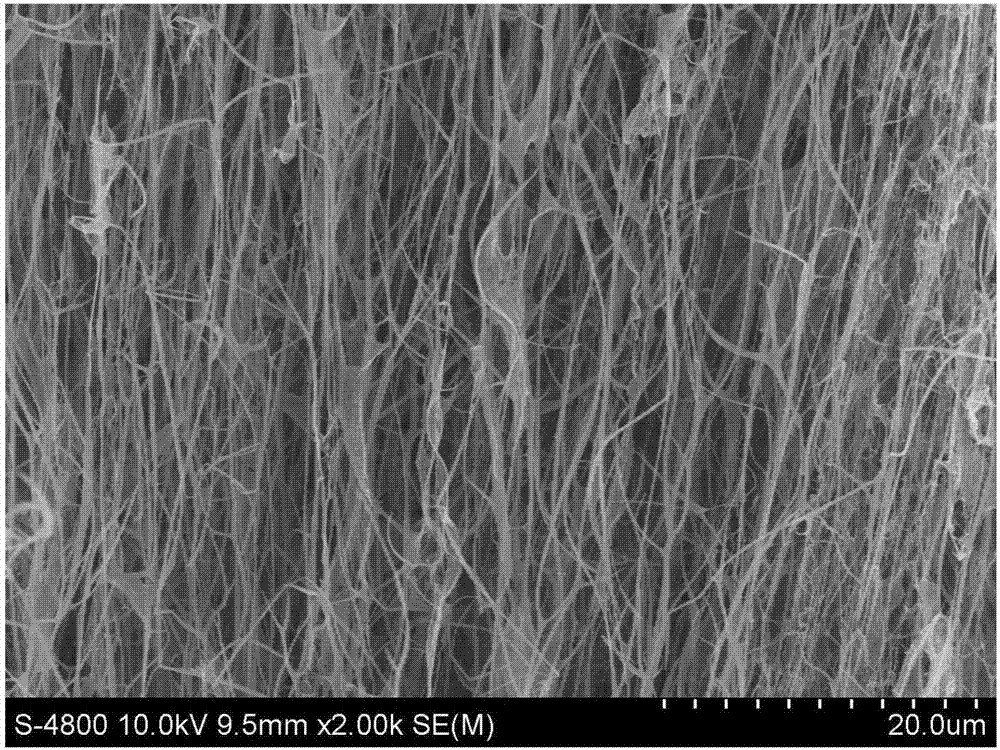

[0030] The solution was diluted to 0.2%, poured into the abo...

Embodiment 2

[0036] The 2% chitosan solution was poured into the nerve conduit mold, frozen at -80° C. for 24 hours, and then freeze-dried to obtain the outer layer chitosan conduit.

[0037] According to the method disclosed in the patent CN101502670B, a rapidly gelled silk fibroin solution is prepared.

[0038] The solution was diluted to 0.5%, poured into the above-mentioned shell conduit, and placed at 37° C. for 2 hours to induce gelation.

[0039] Insert the catheter vertically into the insulation material, along the axial direction of the catheter at a speed of 1×10 -6 m / s immersed in liquid nitrogen for directional freezing;

[0040] The frozen catheter is placed in a lyophilizer for freeze-drying, and aligned silk fibroin nanofibers are formed inside the collagen catheter to form a nerve catheter with the silk fibroin nanofiber orientation guiding function.

Embodiment 3

[0042] The 2% collagen solution was poured into the nerve conduit mold, frozen at -80° C. for 24 hours, and then freeze-dried to obtain the outer collagen conduit.

[0043] According to the method disclosed in patent CN106421902A, a rapidly gelled silk fibroin solution is prepared.

[0044] The silk fibroin solution was diluted to 0.01%, poured into the above-mentioned shell conduit, and placed at 37° C. for 24 hours to induce gelation.

[0045] Insert the catheter vertically into the insulation material, along the axial direction of the catheter at a speed of 1×10 -4 m / s immersed in liquid nitrogen for directional freezing;

[0046] The frozen catheter is placed in a lyophilizer for freeze-drying, and aligned silk fibroin nanofibers are formed inside the collagen catheter to form a nerve catheter with the silk fibroin nanofiber orientation guiding function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com