A kind of application of graphene in epoxy resin composite material

A technology of epoxy resin and composite material, applied in the field of polymer material science, can solve the problems of poor compatibility of polymer materials, low reactivity of graphene, difficult polymer materials, etc. The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

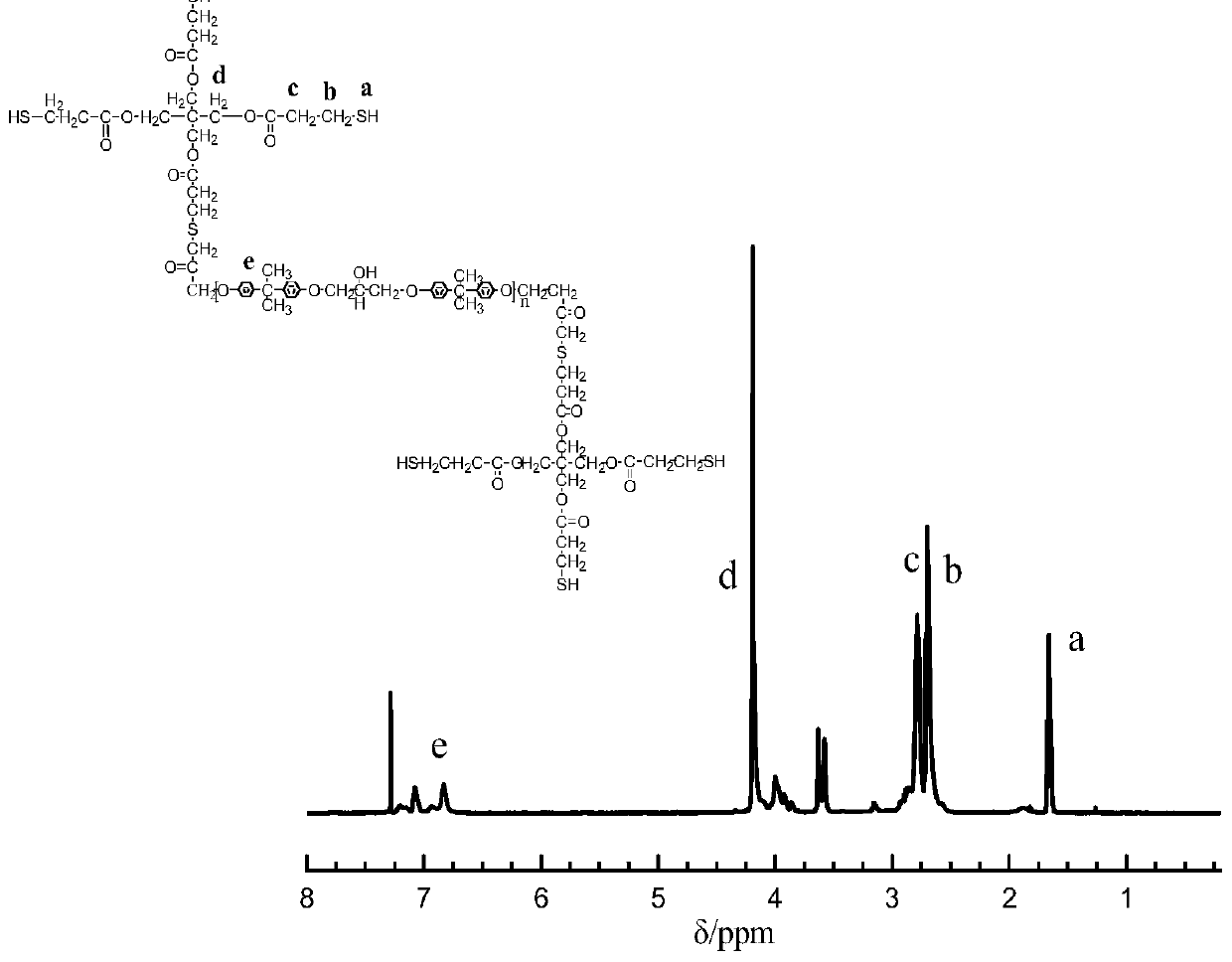

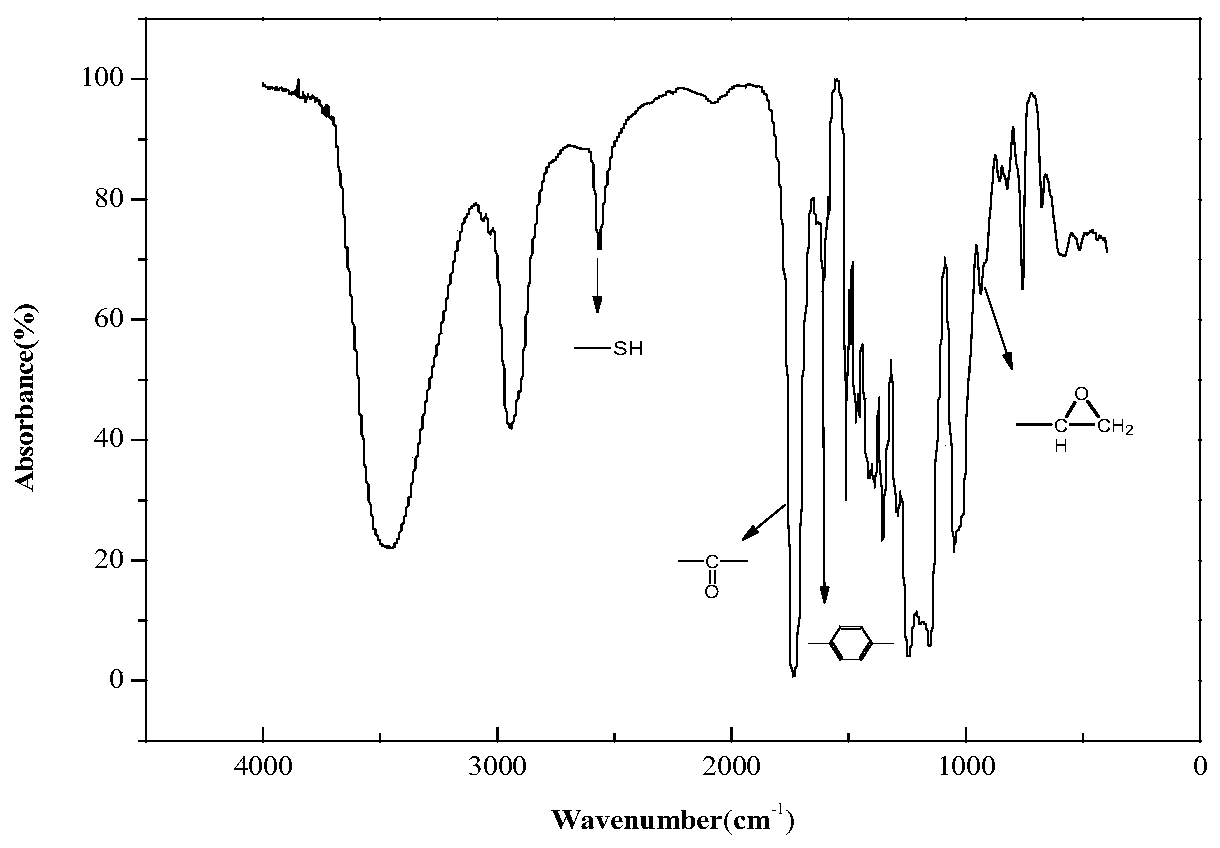

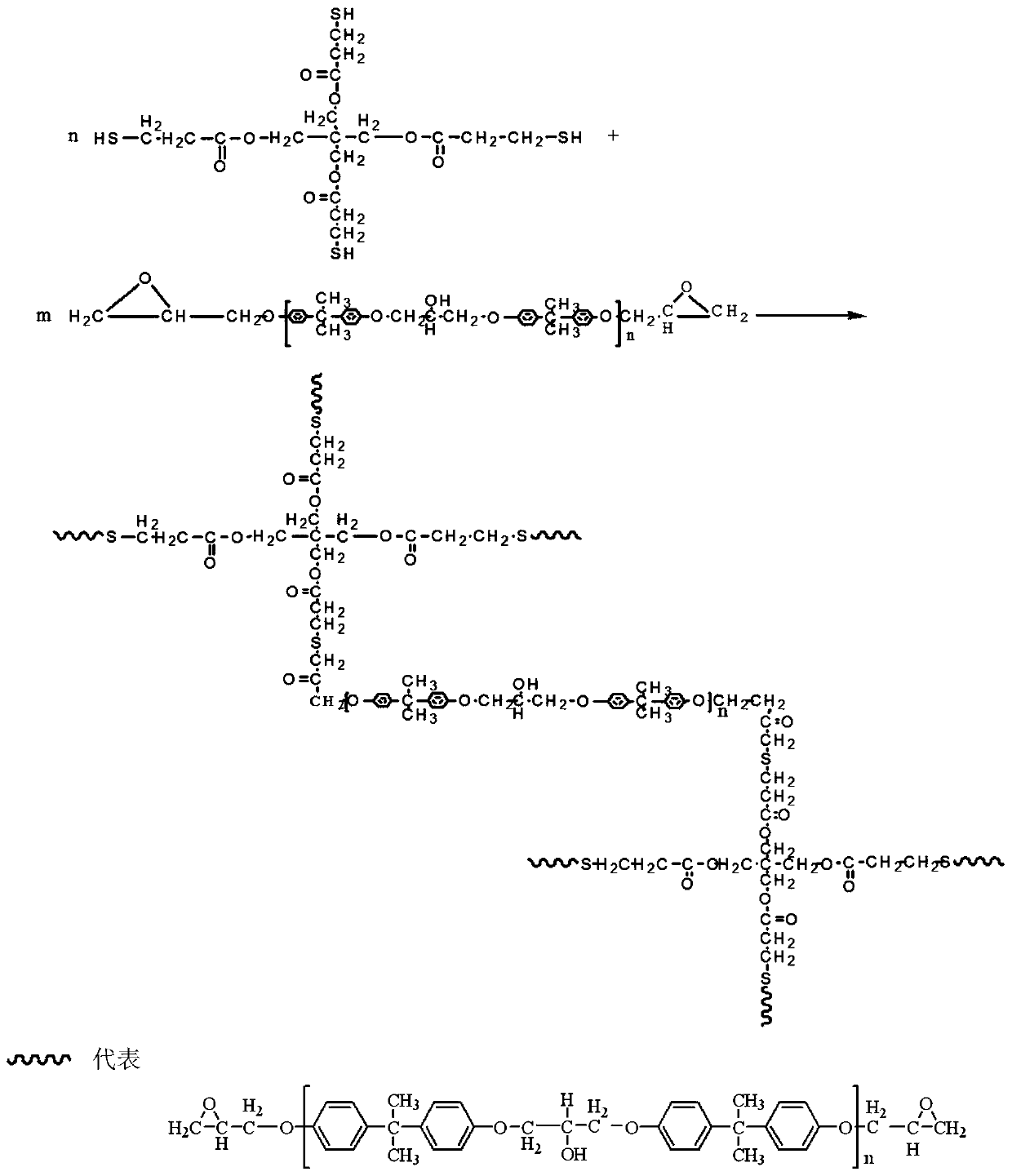

[0036] (1) Synthesis of curing agent pentaerythritol tetramercapto propionate epoxy resin prepolymer (PPTM)

[0037] Add raw material 3-mercaptopropionic acid (44.48g, 0.42mol), pentaerythritol (15.13g, 0.11mol), catalyst p-toluenesulfonic acid (0.90g, 0.0052mol), solvent toluene (90.06mL, 1.13 mol) and a stir bar. Put the three-neck flask into the oil pan, set up the oil-water separator and the spherical condenser in sequence, control the temperature in the oil pan at 110°C, and reflux for 8 hours. When the reaction proceeds to about 2 hours, water will appear in the oil-water separator, and the liquid in the flask will change from cloudy to clear as the reaction progresses. After the reaction, the solution was filtered through a funnel, and the filtered object was washed with alkali to neutrality, and then the washed solution was distilled under reduced pressure to obtain a colorless oily liquid. The solution was purified by acetic acid and petroleum ether (1:1) to obtain ...

Embodiment 2

[0042] Under the situation of not changing other proportions of Example 1, only change graphene to account for the percentage by weight of epoxy resin (128) to be 0%, component A and component B are mixed uniformly, join in the tetrafluoroethylene model plate Prepare a sample, and test the tensile properties of the prepared sample after fully curing.

Embodiment 3

[0044]Under the situation of not changing other proportions of Example 1, only changing graphene to account for epoxy resin (128) weight percentage is 5%, component A and component B are mixed uniformly, join in the tetrafluoroethylene model plate Prepare a sample, and test the tensile properties of the prepared sample after fully curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com