Hyperbranched polymer modified graphene oxide in water phase and method for preparing hyperbranched polymer modified graphene oxide

A technology of hyperbranched polymers and graphene, applied in chemical instruments and methods, medical preparations of non-active ingredients, pharmaceutical formulations, etc., can solve problems such as unfavorable large-scale applications, and achieve a simple and easy reaction process. The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific method of hyperbranched polymer modified graphene oxide is as follows:

[0024] (1) Take 30 mg of graphene oxide powder, add 30 mL of deionized water, and ultrasonically obtain a stable dispersion of 1 mg / mL graphene oxide dispersion for 4 hours;

[0025] (2) Add 2.584g 1-(2-aminoethyl)piperazine to the dispersion prepared in step (1), and stir at 30°C for 24 hours;

[0026] (3) Add 3.083g of N,N-methylenebisacrylamide to the reaction system in step (2), and continue stirring at a constant temperature of 30°C for 60 hours to obtain 1 mg / mL hyperbranched polymer / hyperbranched polymer modified A mixed solution of graphene oxide;

[0027] (4) The reaction solution prepared in step (3) is placed in a dialysis bag of 8-14kDa, and dialyzed for one week, the graphene oxide modified by hyperbranched polymer can be obtained;

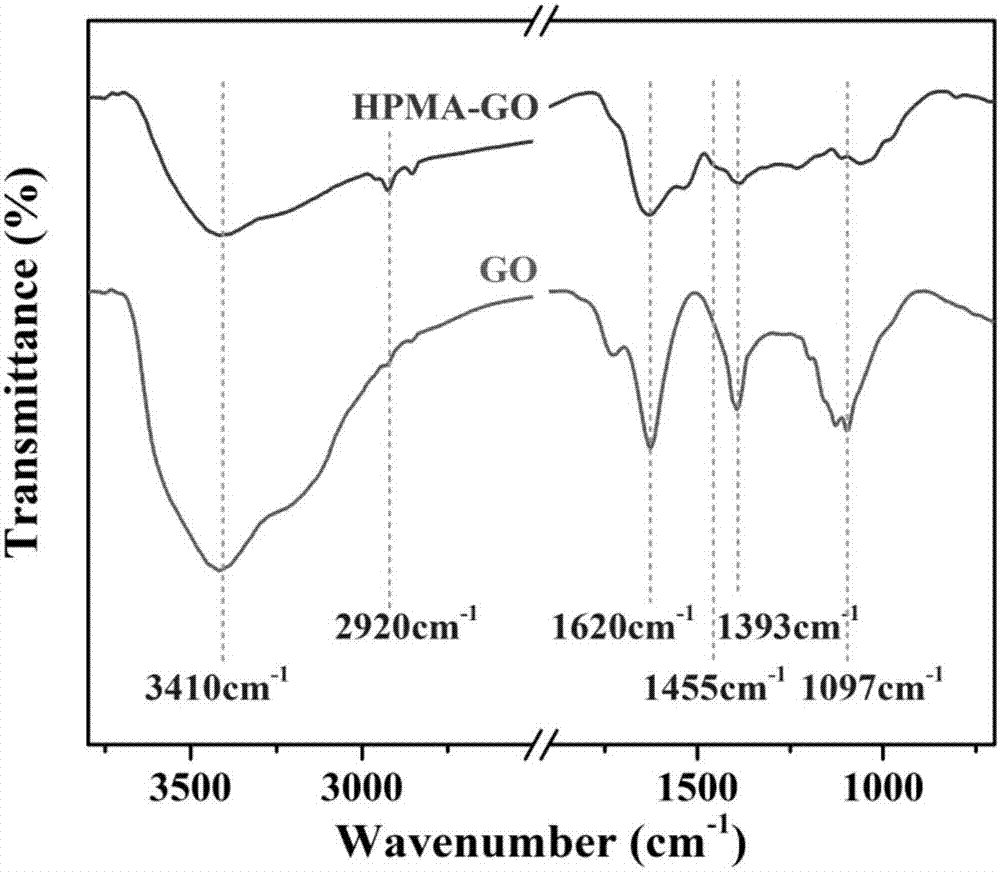

[0028] To characterize the prepared figure 1 Infrared spectra of graphene oxide materials before and after modification, where 2920cm -1 ...

Embodiment 2

[0030] The specific method of hyperbranched polymer modified graphene oxide is as follows:

[0031] (1) Prepare a 1 mg / mL graphene oxide dispersion by ultrasonication for 4 hours, take 1 mL of the dispersion and add deionized water to dilute to 30 mL;

[0032] (2) Add 2.584g 1-(2-aminoethyl)piperazine to the dispersion prepared in step (1), and stir at 30°C for 24 hours;

[0033] (3) Add 3.083 g of N,N-methylenebisacrylamide to the reaction system in step (2), and continue stirring at a constant temperature of 30°C for 48 hours;

[0034] (4) Add deionized water to the solution in step (3), and dilute to 500mL to obtain a mixed solution of hyperbranched polymer / hyperbranched polymer modified graphene oxide with a graphene oxide concentration of 2mg / L.

[0035] Use this solution to prepare pervaporation membranes on the surface of inorganic ceramic materials, and pretreat the inorganic tubular membranes: immerse the inorganic membranes in 3-amino-triethoxysilane ethanol solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com