Friction material for brake pad and preparation method of friction material

A technology of friction material and brake pad, applied in the field of friction material for brake pad and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

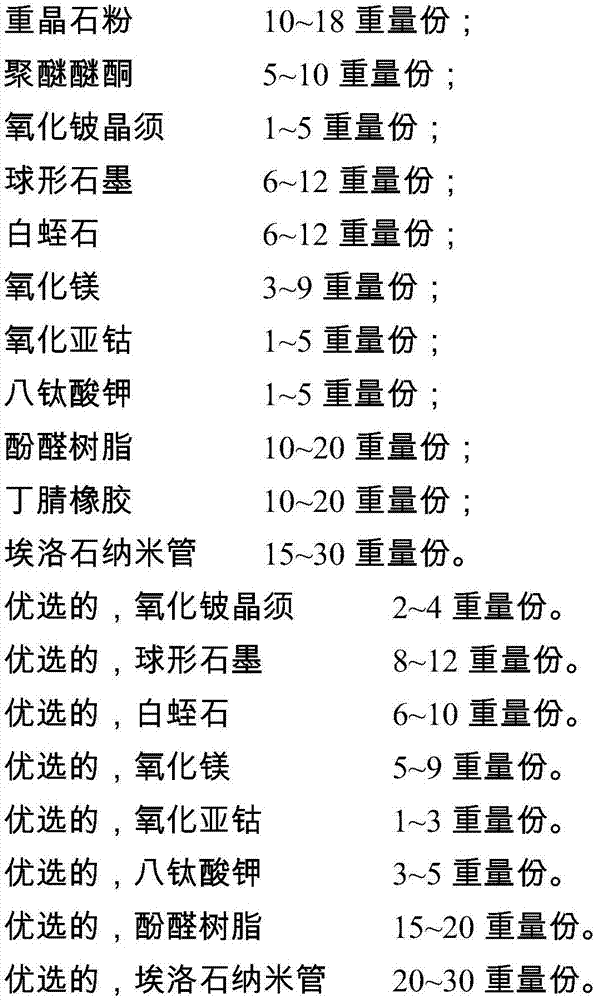

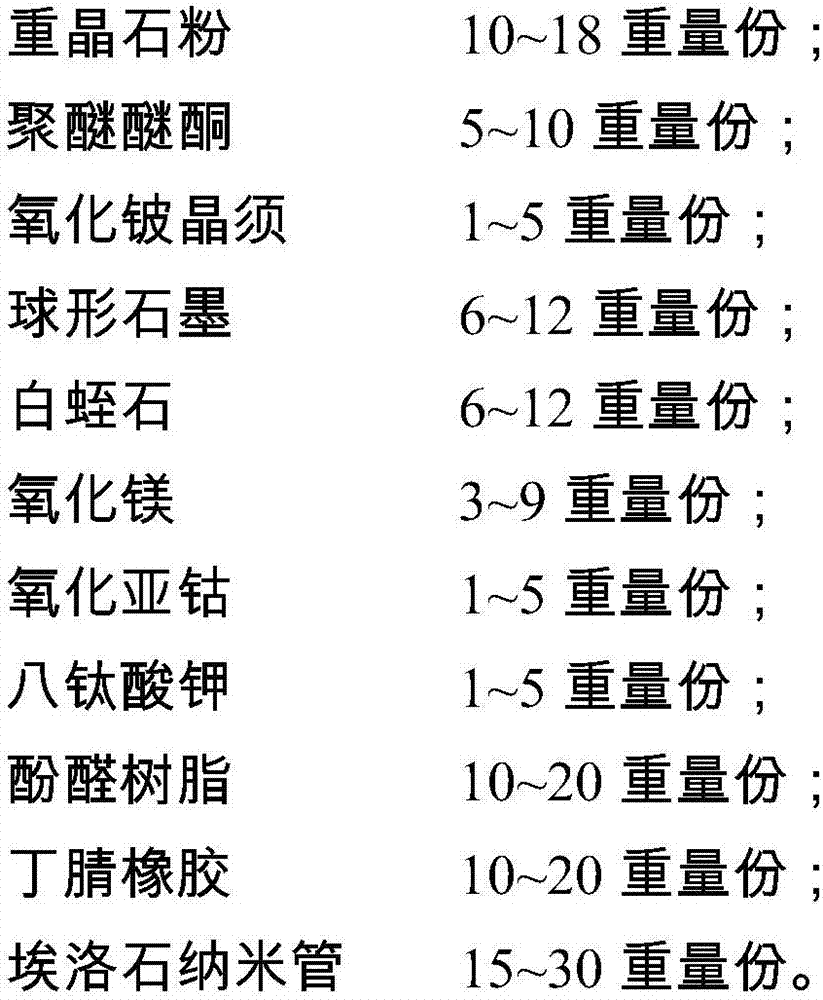

[0014] Correspondingly, the present invention also provides a method for preparing a friction material for a brake pad, comprising the following steps: mixing 10-18 parts by weight of barite powder, 5-10 parts by weight of polyether ether ketone, and 1-5 parts by weight of beryllium oxide whiskers 6-12 parts by weight of spherical graphite, 6-12 parts by weight of white vermiculite, 3-9 parts by weight of magnesium oxide, 1-5 parts by weight of cobaltous oxide, 1-5 parts by weight of potassium octatitanate, 10-5 parts by weight of phenolic resin 20 parts by weight, 10 to 20 parts by weight of nitrile rubber, and 15 to 30 parts by weight of halloysite nanotubes are mixed, stirred for 2-3 hours to obtain a uniform mixture; Under the condition of hot pressing at 160°C for 1 hour, heat treatment at 200°C for 5 hours, grinding and spraying to obtain the friction material for brake pads.

[0015] As can be seen from the above scheme, the present invention uses barite powder, polyeth...

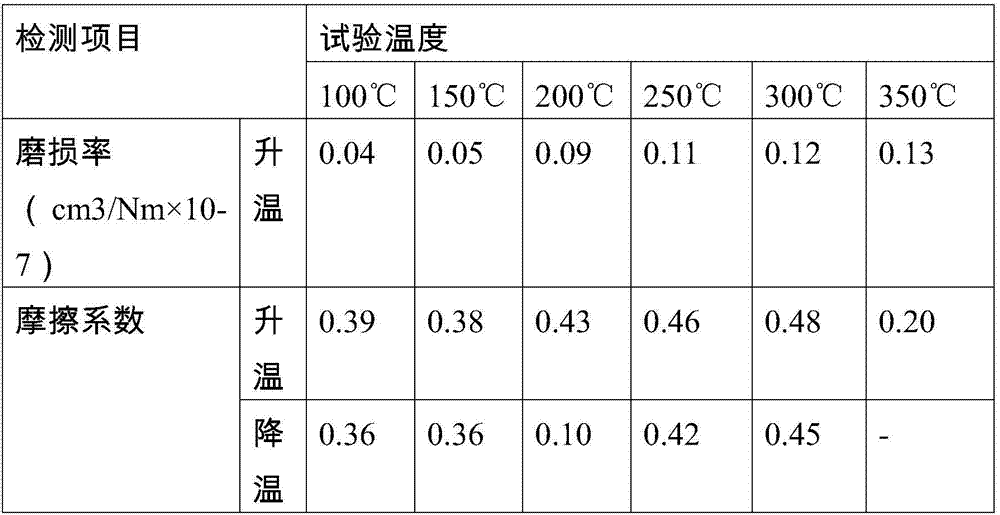

Embodiment 1

[0019] 1) First prepare a 0.06mol / L nitric acid solution, then weigh 15-30 parts by weight of halloysite and disperse it into the nitric acid solution to form a mixture. After ultrasonic treatment for 10 hours, transfer it to a hydrothermal reaction kettle for treatment at 120°C 8h, after cooling to room temperature, filter and wash with deionized water, and dry at 110°C for 15h;

[0020] 2) 10 parts by weight of barite powder, 10 parts by weight of polyetheretherketone, 1 part by weight of beryllium oxide whiskers, 12 parts by weight of spherical graphite, 6 parts by weight of white vermiculite, 9 parts by weight of magnesium oxide, and 1 part by weight of cobaltous oxide 5 parts by weight of potassium octatitanate, 10 parts by weight of phenolic resin, 20 parts by weight of nitrile rubber and the halloysite nanotubes prepared above are mixed, and stirred for 2-3h;

[0021] 3) Put the homogeneous mixture obtained in step 2 into a hot-pressing mold and hot-press at 160°C under...

Embodiment 2

[0027] 1) First prepare a 0.06mol / L nitric acid solution, then weigh 15-30 parts by weight of halloysite and disperse it into the nitric acid solution to form a mixture. After ultrasonic treatment for 10 hours, transfer it to a hydrothermal reaction kettle for treatment at 120°C 8h, after cooling to room temperature, filter and wash with deionized water, and dry at 110°C for 15h;

[0028] 2) 18 parts by weight of barite powder, 5 parts by weight of polyether ether ketone, 5 parts by weight of beryllium oxide whiskers, 6 parts by weight of spherical graphite, 12 parts by weight of white vermiculite, 3 parts by weight of magnesium oxide, and 5 parts by weight of cobaltous oxide part, 1 part by weight of potassium octatitanate, 20 parts by weight of phenolic resin, 10 parts by weight of nitrile rubber and the halloysite nanotubes prepared above are mixed, and stirred for 2-3h;

[0029] 3) Put the homogeneous mixture obtained in step 2 into a hot-pressing mold and hot-press at 160...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com