Preparation method of salt-resisting stable-type drag reducer

A stable, drag-reducing agent technology, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as poor salt resistance and drag reduction performance, and achieve enhanced salt resistance, Excellent salt tolerance and salt storage performance, the effect of slowing down the exchange rate and extent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

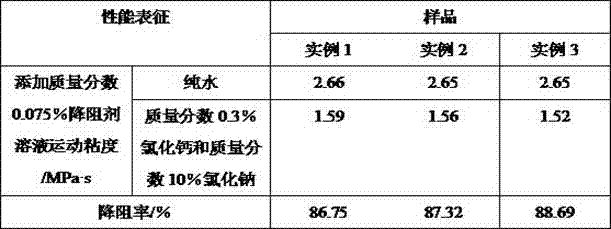

Examples

example 1

[0018] Take fresh Salicornia and wash, freeze-dry and grind through a 50-mesh sieve, collect Salicornia granules and mix Salicornis granules with a mass fraction of 5% and a pH of 6.5 sodium dihydrogen phosphate- Stir and mix the disodium hydrogen phosphate solution, ultrasonically disperse at 200W for 10min, collect the dispersion and add the mixed enzyme to the dispersion at 50U / mL, stir and mix at room temperature for 1h, heat to boil and keep warm for 3min, Use glacial acetic acid to adjust the pH to 4.0, centrifuge at 8000r / min and collect the lower precipitate, rinse with 80% ethanol solution for 3 times, vacuum freeze-dry to obtain Salicornia fiber; weigh in parts by weight Put 25 parts of acetone, 10 parts of glutaraldehyde, and 75 parts of deionized water in a beaker, stir and mix and add glacial acetic acid dropwise until the pH reaches 5.0, and control the dropping rate of glacial acetic acid to 0.2mL / min. , to obtain a modified solution, and according to the mass r...

example 2

[0020] Take fresh Salicornia and wash, freeze-dry and grind through a 50-mesh sieve, collect Salicornia granules and mix Salicornis granules with a mass fraction of 5% and a pH of 6.5 sodium dihydrogen phosphate- Stir and mix the disodium hydrogen phosphate solution, ultrasonically disperse at 250W for 12 minutes, collect the dispersion and add the mixed enzyme to the dispersion at 50 U / mL, stir and mix at room temperature for 2 hours, heat to boil and keep warm for 4 minutes, Use glacial acetic acid to adjust the pH to 4.0, centrifuge at 9000r / min and collect the lower precipitate, rinse with 80% ethanol solution for 4 times, vacuum freeze-dry to obtain Salicornia fiber; weigh in parts by weight Put 27 parts of acetone, 12 parts of glutaraldehyde, and 77 parts of deionized water in a beaker, stir and mix and add glacial acetic acid dropwise until the pH reaches 5.0, and control the dropping rate of glacial acetic acid to 0.2mL / min. , to obtain a modified solution, and accordi...

example 3

[0022] Take fresh Salicornia and wash, freeze-dry and grind through a 50-mesh sieve, collect Salicornia granules and mix Salicornis granules with a mass fraction of 5% and a pH of 6.5 sodium dihydrogen phosphate- Stir and mix the disodium hydrogen phosphate solution, ultrasonically disperse at 300W for 15 minutes, collect the dispersion and add the mixed enzyme to the dispersion at 50 U / mL, stir and mix at room temperature for 2 hours, heat to boil and keep warm for 5 minutes, Use glacial acetic acid to adjust the pH to 4.0, centrifuge at 10000r / min and collect the lower precipitate, rinse with 80% ethanol solution for 5 times, and vacuum freeze-dry to obtain Salicornia fiber; weigh in parts by weight Put 30 parts of acetone, 15 parts of glutaraldehyde, and 80 parts of deionized water in a beaker, stir and mix and add glacial acetic acid dropwise until the pH reaches 5.0, and control the dropping rate of glacial acetic acid to 0.2mL / min. , to obtain a modified solution, and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com