Gradient control method of fused salt chlorination system temperature

A temperature gradient, chlorination system technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of dust collector detachment, system pressure instability, titanium recovery rate decline, etc., to reduce the thermal resistance of fouling, Simple process and the effect of prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

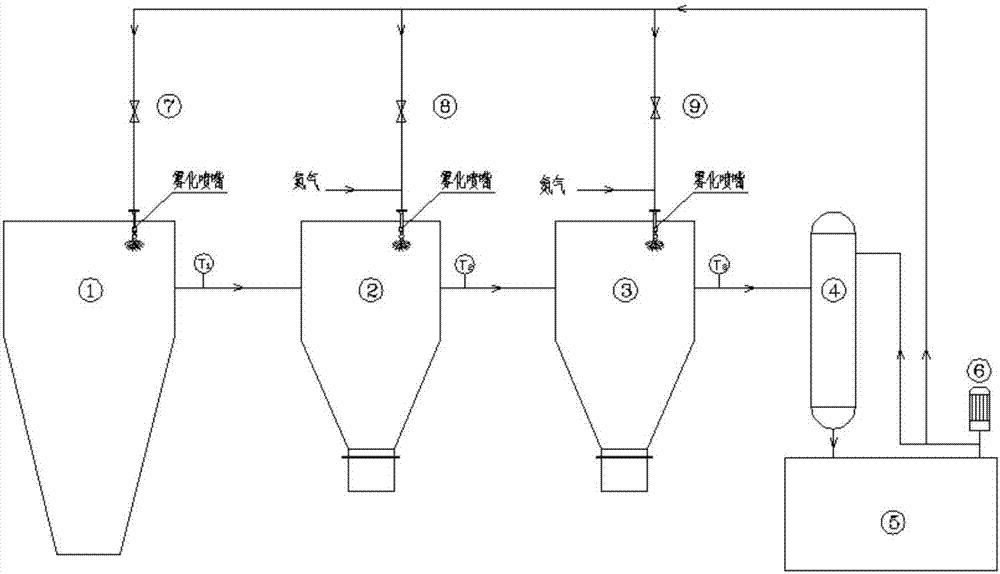

[0021] Such as figure 1 As shown, the molten salt chlorination temperature gradient control system is adopted. Under normal production conditions, the titanium tetrachloride-containing mud pump ⑥ is turned on, and the outlet pressure is controlled to 1.5MPa, and the flow rate is 100m 3 / h; control access 1 # Dust collector ② and 2 # The nitrogen pressure of the dust collector ③ is 0.5MPa, open the mud control valve ⑦ of the molten salt chlorination furnace, adjust the valve opening according to the outlet temperature T1 of the molten salt chlorination furnace ①, and control the outlet temperature T1 of the molten salt chlorination furnace ① to 450 ℃~500℃; turn on and return to 1 # Dust collector mud control valve ⑧, according to 1 # Dust collector ② outlet temperature T2 to adjust the valve opening, control 1 # The outlet temperature T2 of dust collector ② is 350℃~370℃; # Dust collector mud control valve ⑨, according to 2 # Dust collector ③ outlet temperature T3 to adjus...

Embodiment 2

[0023] Such as figure 1 As shown, the molten salt chlorination temperature gradient control system is adopted. Under normal production conditions, the titanium tetrachloride return mud pump ⑥ is turned on, and the outlet pressure is controlled to 1.2MPa, and the flow rate is 80m 3 / h m 3 / h; control access 1 # Dust collector ② and 2 # The nitrogen pressure of the dust collector ③ is 0.2 MPa, open the mud control valve ⑦ of the molten salt chlorination furnace, adjust the valve opening according to the outlet temperature T1 of the molten salt chlorination furnace ①, and control the outlet temperature T1 of the molten salt chlorination furnace ① to 600 ℃~650℃; turn on and return to 1 # Dust collector ② mud control valve ⑧, according to 1 # Dust collector ② outlet temperature T2 to adjust the valve opening, control 1 # The outlet temperature T2 of the dust collector ② is 380 ° C ~ 400 ° C; # Dust collector ③ mud control valve ⑨, according to 2 # Dust collector ③ outlet te...

Embodiment 3

[0025] Such as figure 1 As shown, the molten salt chlorination temperature gradient control system is adopted. Under normal production conditions, the titanium tetrachloride-containing mud pump ⑥ is turned on to control the outlet pressure to 1.4MPa and the flow rate to 90m 3 / h; control access 1 # Dust collector ② and 2 # The nitrogen pressure of the dust collector ③ is 0.3MPa, open the mud control valve ⑦ of the molten salt chlorination furnace ①, adjust the valve opening according to the outlet temperature T1 of the molten salt chlorination furnace ①, and control the outlet temperature T1 of the molten salt chlorination furnace ① to 500 ℃~550℃; turn on and return to 1 # Dust collector mud control valve ⑧, according to 1 # Dust collector outlet temperature T2 to adjust valve opening, control 1 # The outlet temperature T2 of the dust collector is 370 ° C ~ 380 ° C; # Dust collector mud control valve ⑨, according to 2 # Dust collector outlet temperature T3 to adjust valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com