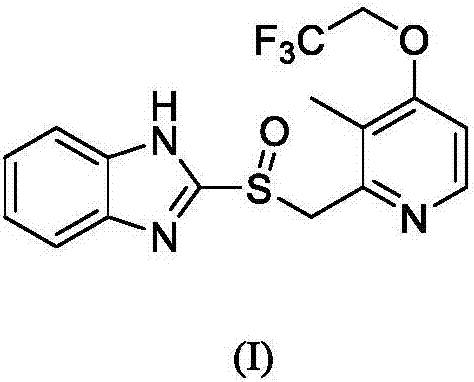

Preparation method of lansoprazole

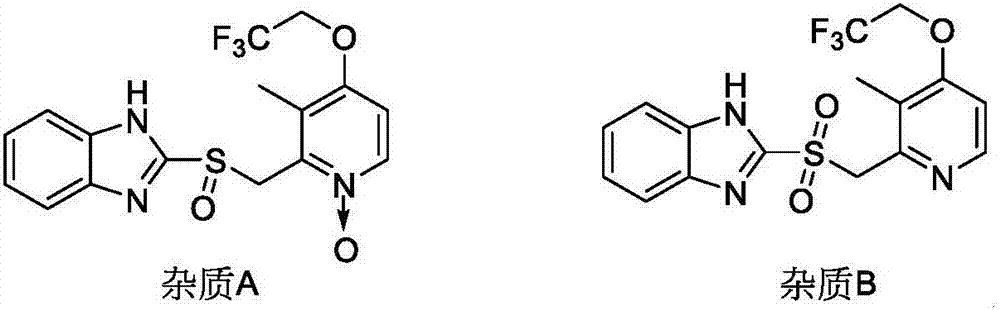

A technology of lansoprazole and solvent, applied in the field of preparation of lansoprazole, can solve the problems of difficult purification and low yield, and achieve the effect of simple process and easy control of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

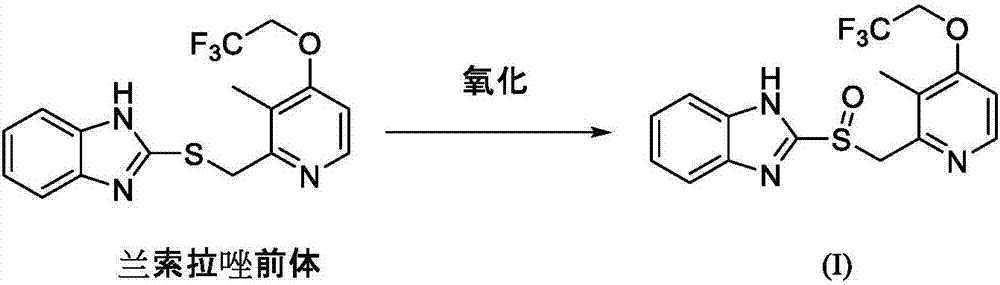

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Lansoprazole preparation

[0032] Add 44.8g of sodium hydroxide (1.12mol), 500ml of ethanol, and 640ml of water into a 3L reaction flask. After stirring and dissolving, add 100g of compound M1 (0.28mol), control the temperature at -5 to 10°C, and slowly add sodium hypochlorite solution (0.36 mol, the available chlorine content is 3.0%), after the dropwise addition is completed, it is incubated at -5 to 10°C for 1 hour, after the reaction is completed, add 10% sodium thiosulfate solution to quench the reaction, and use 20% acetic acid Adjust the pH to 7-9, then control the temperature and stir for 1 hour at 0°C, filter, wash with purified water, and dry the wet product in a vacuum oven to obtain 84.5 g of light yellow solid, which is the crude product of lansoprazole. Yield 81%, impurity A: <0.1%, impurity B: <0.1%, purity: 99.58%.

[0033] Add 80g of lansoprazole crude product into 800ml of acetone, heat and reflux until dissolved, filter the insoluble mat...

Embodiment 2

[0034] Embodiment 2 Lansoprazole preparation

[0035] Add 5.6g of sodium hydroxide (0.14mol), 50ml of isopropanol, and 60ml of water into a 250mL reaction flask, stir and dissolve, add 10g of compound M1 (0.028mol), control the temperature at -5~10°C, and slowly add sodium hypochlorite solution dropwise (0.039mol, available chlorine content 3.5%), after the dropwise addition was completed, it was incubated and reacted at -5~10°C for 1 hour, HPLC detected M1<0.5%, stopped the reaction, added 10% sodium thiosulfate solution to quench the reaction, and detected After no oxidation, use 20% acetic acid to adjust the pH to 7-9. After the adjustment, control the temperature and stir at 0°C for 1 hour, filter, wash with purified water, and dry the wet product in a vacuum oven to obtain 8.7g of light yellow The solid is crude lansoprazole, with a yield of 83%, impurity A: <0.1%, impurity B: <0.1%, and purity: 99.71%.

[0036] Add 6.0g of crude lansoprazole into 60ml of acetone, heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com