A drug-loaded aqueous emulsion containing modified polymannuronic acid derivatives and its preparation method

A technology of polymannuronic acid and its derivatives, applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of large dosage, large residue, short duration, etc., to improve growth Effects of adaptability, drought resistance improvement, and property stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

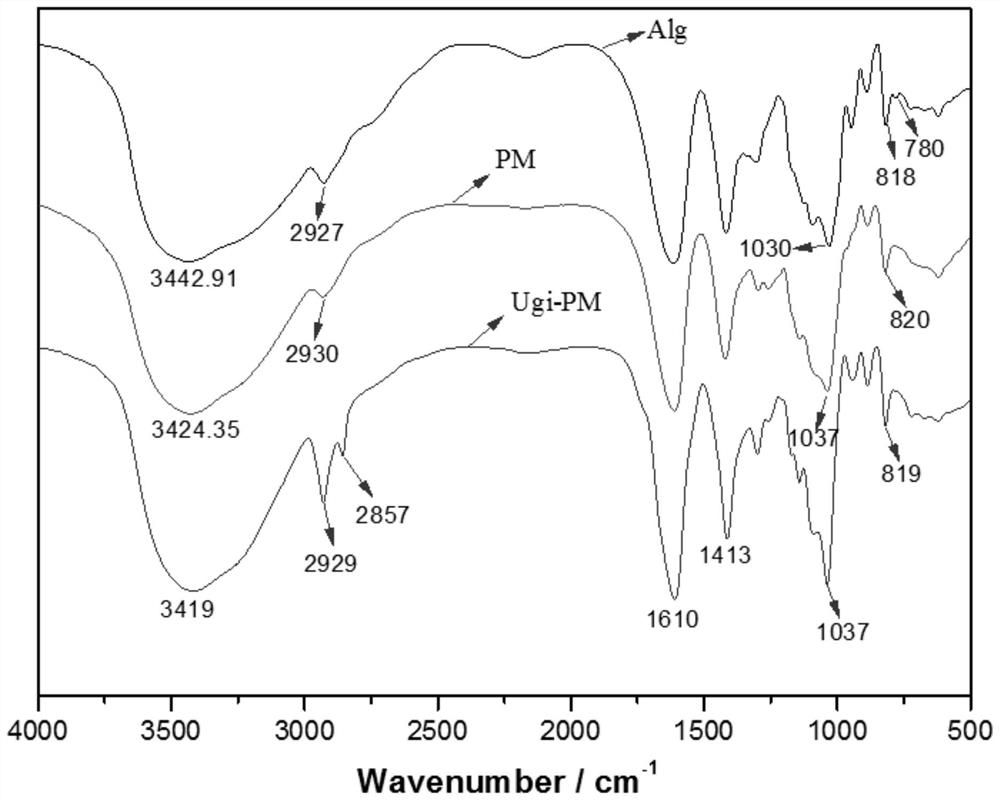

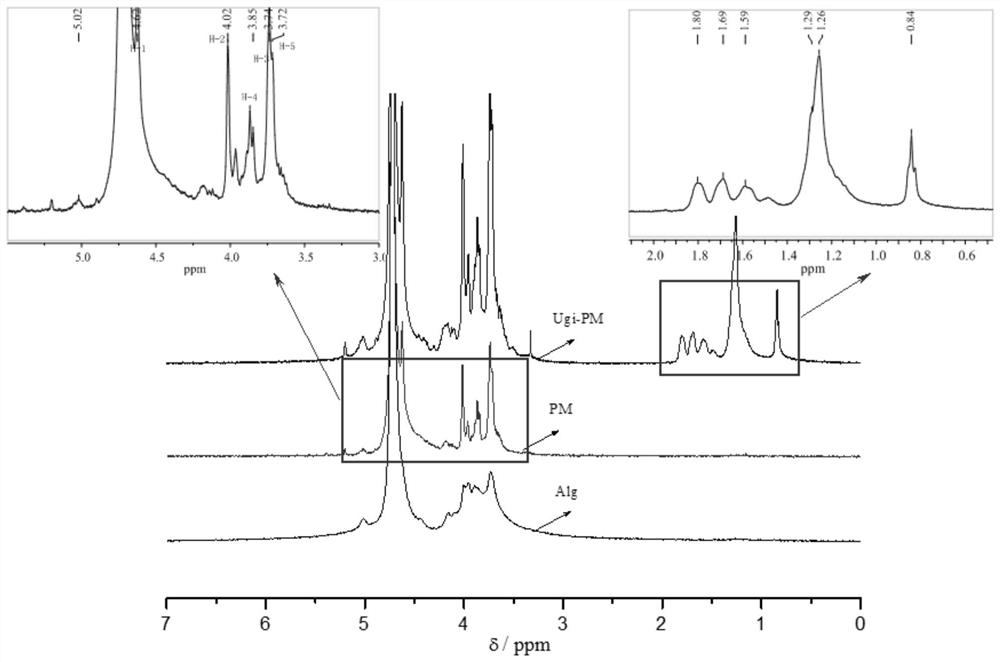

[0034] A preparation method of modified polymannuronic acid derivative (Ugi-PM), comprising the following steps:

[0035] Take polymannuronic acid and add it to a three-necked flask, add deionized water that is 35-45 times the mass of polymannuronic acid, stir it mechanically to dissolve it completely, and use dilute hydrochloric acid to adjust the pH to 2.8;

[0036] Then add formaldehyde solution and octylamine respectively to make the system fully stir and mix evenly, finally add cyclohexyl isocyanide, stir and react for 20 hours; the amount of formaldehyde solution, octylamine and cyclohexyl isocyanide is: Add, 0.03g of formaldehyde solution, 0.1g of octylamine, 0.1g of cyclohexyl isocyanide with a mass concentration of 98%; the mass concentration of the added formaldehyde solution is 35%;

[0037] After the reaction is completed, dilute the reaction solution with water to 2 times and let it stand for defoaming; place the diluted solution in a molecular weight cut-off (Mw=...

Embodiment 2

[0042] A preparation method of modified polymannuronic acid derivative (Ugi-PM), comprising the following steps:

[0043] Take polymannuronic acid and add it to a three-necked flask, add deionized water 45 times the mass of polymannuronic acid, stir mechanically to dissolve it completely, and use dilute hydrochloric acid to adjust the pH to 3.2;

[0044] Then add formaldehyde solution and octylamine respectively to make the system fully stir and mix evenly, and finally add cyclohexyl isocyanide, stir and react for 30 hours; the amount of formaldehyde solution, octylamine and cyclohexyl isocyanide is: Add, 0.07g of formaldehyde solution, 0.2g of octylamine, 0.3g of cyclohexyl isocyanide whose mass concentration is 98%; the mass concentration of formaldehyde solution is 40%;

[0045] After the reaction, dilute the reaction solution with water to 4 times and let it stand for defoaming; place the diluted solution in a molecular weight cut-off (Mw=1000) dialysis bag, and dialyze in d...

Embodiment 3

[0050] A preparation method of hydrophobically modified polymannuronic acid derivative (Ugi-PM), comprising the following steps:

[0051] Take polymannuronic acid and add it to a three-necked flask, add deionized water 40 times the mass of polymannuronic acid, mechanically stir to dissolve it completely, and use dilute hydrochloric acid to adjust the pH to 3.0;

[0052] Then add formaldehyde solution and octylamine respectively to make the system fully stir and mix evenly. Finally, add cyclohexyl isocyanide and fully stir for 24 hours. The amount of formaldehyde solution, octylamine and cyclohexyl isocyanide is: Add, 0.05g of formaldehyde solution, 0.17g of octylamine, 0.2g of cyclohexyl isocyanide whose mass concentration is 98%; the mass concentration of formaldehyde solution is 37%;

[0053] After the reaction, dilute the reaction solution with water to 3 times and let it stand for defoaming; place the diluted solution in a molecular weight cut-off (Mw=1000) dialysis bag, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com